Novel workbench driven by friction pull rod

A workbench, a new type of technology, is applied in the fields of cutting-edge industrial production and scientific research, which can solve the problems of low positioning accuracy and achieve the effects of high positioning accuracy, good rigidity and long working stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

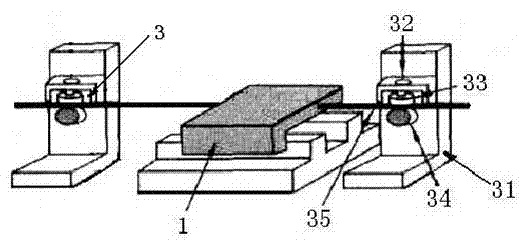

[0012] refer to figure 1 As shown, a novel workbench driven by a friction pull rod includes a light workbench 1, a granite guide rail 2 and a drive mechanism 3, and the light workbench 1 is floatingly arranged above the granite guide rail 2. The drive mechanism 3 includes an L-shaped base plate 31, a C-shaped pre-loaded plate 32 is installed on the vertical plate of the L-shaped base plate 31, and an air cushion 33 and a motor friction wheel are sequentially installed below the C-shaped pre-loaded plate 32. 34. A traction rod 35 is arranged between the air cushion 33 and the motor friction wheel 34, and the traction rod 35 is connected with the lightweight workbench 1.

[0013] Further, the inner surface of the lightweight workbench 1 is in sliding contact with the side surface of the granite guide rail 2, the opening of the C-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com