Full-automatic assembly machine for mobile phone screens

A mobile phone screen and assembly machine technology, applied in hand-held tools, metal processing, metal processing equipment, etc., can solve the problems of low assembly consistency and precision, high labor intensity of employees, and high proportion of misoperations, and achieve good consistency , Reduce labor intensity, high assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing:

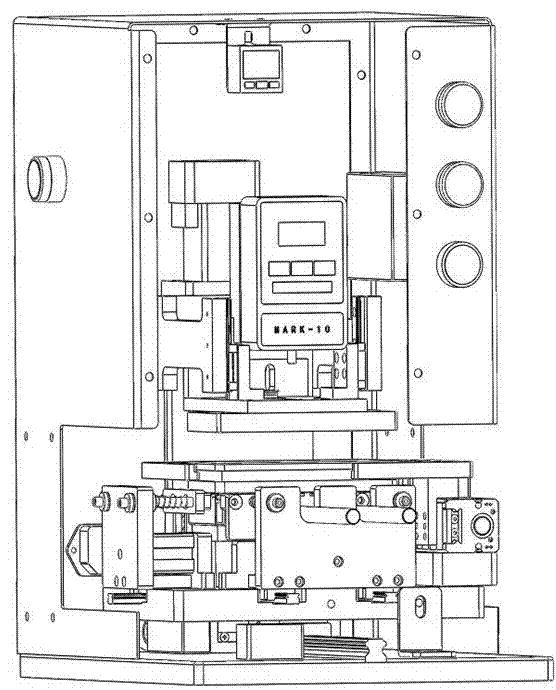

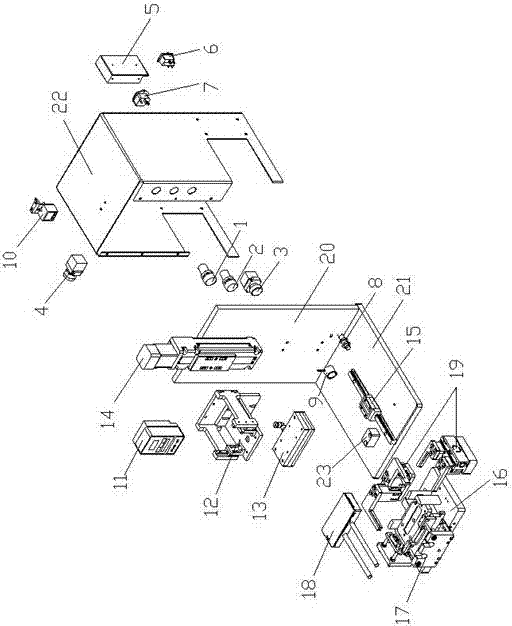

[0011] Such as figure 1 , 2 , 3, 4, the power indicator light 1, the work indicator light 2, the start button 3 are installed on the front of the shell 22, the reset / emergency stop button 4 is installed on the side outer wall of the shell 22, the power switch 6, the power jack 7 is fixed on the rear outer wall of the housing 22, the actuator fixing plate 20 is vertically fixed on the rear end surface of the bottom plate 21, the electric actuator 14 is fixed on the inner surface of the actuator fixing plate 20, and the pressing connection mechanism 12 is fixed on the electric actuator 14. On the fixed plate that comes with it, the pressure gauge 11 is fixed on the upper end surface of the lower connection mechanism 12 base, the vacuum pressure head 13 is fixed on the lower end surface of the lower connection mechanism 12 base, and the vacuum sensor 10 is fixed on the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com