Automatic pet feeding machine

A pet and automatic technology, applied in animal feeding devices, poultry industry, program control in sequence/logic controllers, etc., can solve problems such as insufficient sanitation, overfeeding, small capacity of pet feeding machines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

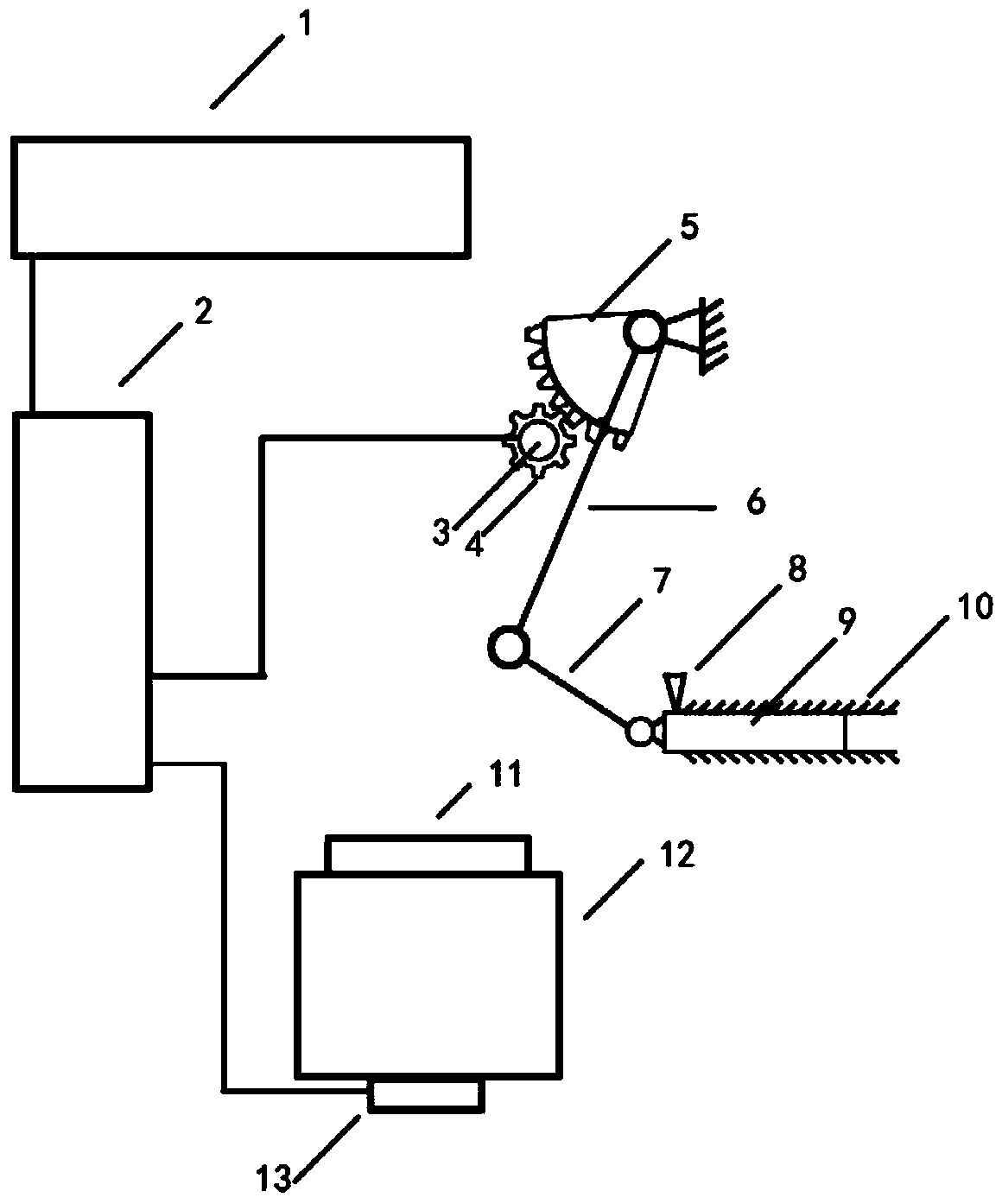

[0016] Such as Figure 1-3 As shown, an automatic pet feeding machine includes a stepping motor 3, a small gear 4, a large gear 5, a rocker 6, a connecting rod 7, a food box cover 11, a food box 12, and a food box valve 13; it also includes a control panel 1. PLC controller 2. Cleaning scraper 8. Slider bottom plate 9. Chute 10. Dirt tray 14. The control panel 1 is connected with the PLC controller 2, and the input command is transmitted to the PLC controller 2 through the control panel 1; the PLC controller 2 is connected with the stepping motor 3. Food box valve 13 is connected with PLC controller 2 simultaneously. Rocking bar 6, connecting rod 7, slider bottom plate 9, and chute 10 form a crank slider mechanism and are fixed inside the pet feeding machine. Wherein the small gear 4 is connected with the stepping motor 3, and rotates with the rotation of the stepping motor; the rocking bar 6 is connected with the large gear 5, and the rocking bar 6 swings with the rotation ...

Embodiment 2

[0025] In order to facilitate the disassembly of the dirt tray 14, the dirt tray 14 can be made into a strip-shaped protrusion on one side and a through hole on the other side; the corresponding side of the slider bottom plate 9 is a groove, and the other side is a groove. Threaded hole. Its fastening method is that the protrusion on one side of the dirt tray 14 is snapped into the groove on one side of the slider bottom plate 9, and the other side is fastened with bolts. . Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com