Gas channeling prevention system of screw feeder

A screw feeder, anti-channeling technology, which is applied in the direction of fuel supply, fuel burning in a molten state, and combustion method, etc., to achieve the effect of simple structure, preventing poor feeding, and timely blocking of channeling gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

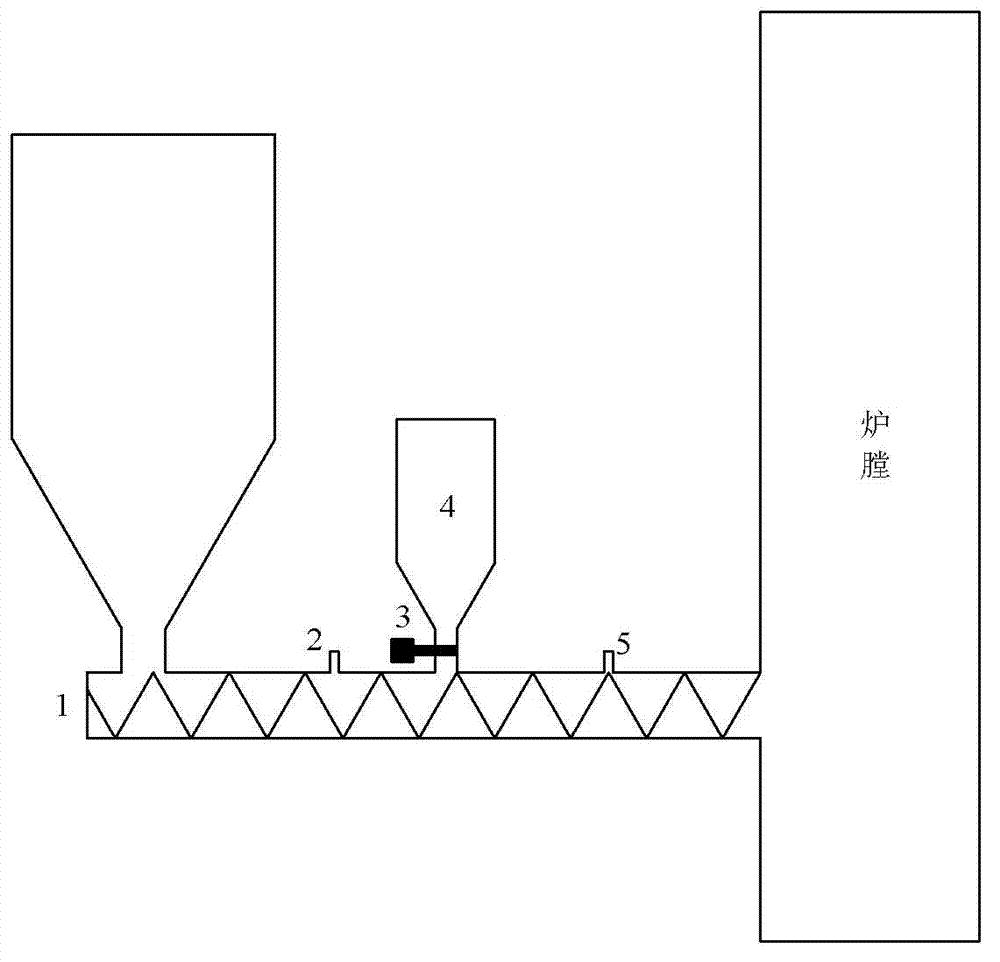

[0039] Such as figure 1 As shown, a single-stage screw feeder 1 feeds biomass molding particles into a circulating fluidized bed furnace, and is equipped with a sensing device, a control device 3, and a storage bin 4 for an anti-channeling gas medium. The anti-channeling gas medium storage silo 4 is filled with sieved kaolin whose average particle size is smaller than the average particle size of biomass molding particles.

[0040] The middle part of the casing of the screw feeder 1 is provided with a first temperature sensor 2 , and the monitored temperature signal is transmitted to the control device 3 . On the casing of the screw feeder 1, an anti-channeling gas medium inlet is provided between the material outlet and the first temperature sensor 2, and the distance between it and the material outlet of the feeder is 4 times the pitch of the screw blade. There is also a plugging detection temperature sensor 5 between the anti-channeling gas medium inlet and the material ou...

Embodiment 2

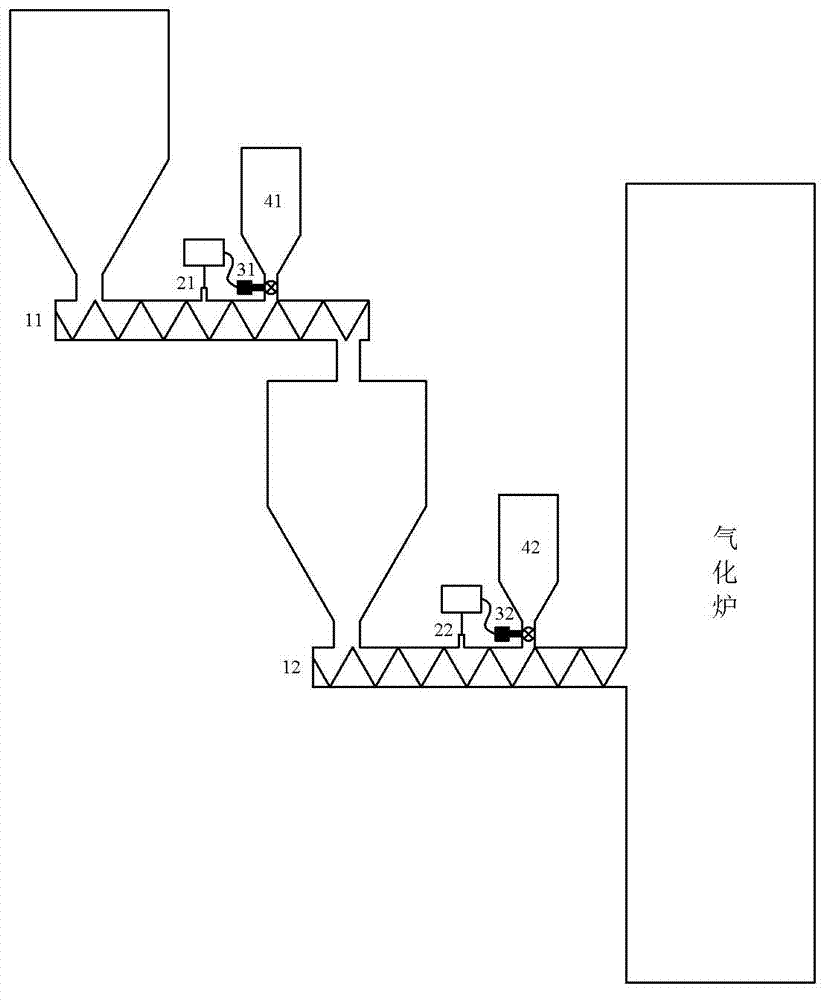

[0043] Such as figure 2 As shown, the two-stage screw feeder feeds coal to the gasifier, the first-stage screw feeder 11 feeds the material to the hopper of the second-stage screw feeder 12, and the second-stage screw feeder 12 is connected to the gasifier. It is the final feeder; screw feeders 11 and 12 are equipped with anti-blow-by gas devices, including sensing devices, control devices 31 and 32, and anti-blow-by gas medium storage bins 41 and 42, respectively. The temperature sensors 21 and 22 of the sensing device are respectively arranged on the casing of the two-stage screw feeder and the rear side of the inlet for the anti-blow-by gas medium. The control valve is a star valve, the distance between the inlet of the anti-channeling gas medium and the material outlet of the feeder is twice the pitch of the helical blade, and the anti-channeling gas medium in the storage bins 41 and 42 of the anti-channeling gas medium and the feed material The materials in the machine ...

Embodiment 3

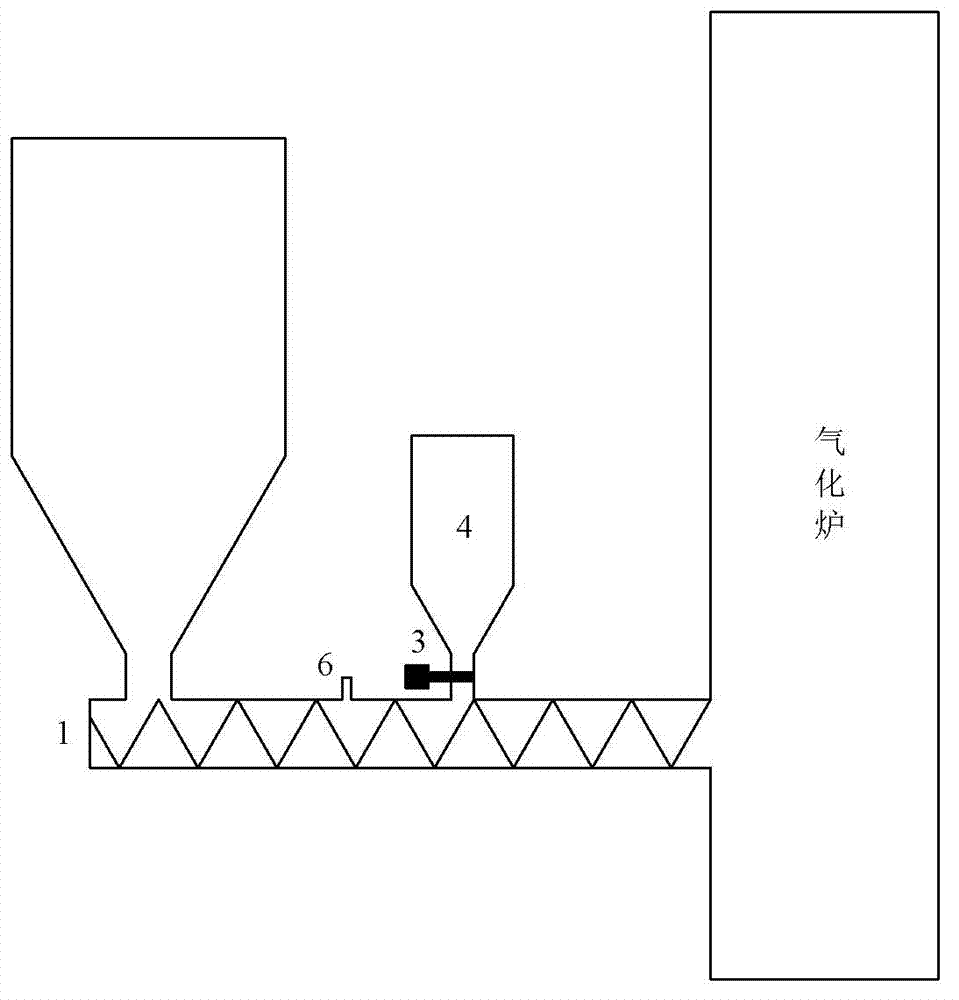

[0047] Such as image 3 As shown, screw feeder 1 feeds fine coal with a particle size of 0-8mm into the gasification furnace. Since the pressure in the gasification furnace is higher than atmospheric pressure, in order to prevent high-temperature gas from entering the feed material under normal feeding conditions In the machine, the protective gas whose pressure is higher than the pressure in the furnace is passed into the screw feeder 1.

[0048] The anti-blow-by device includes a sensing device, a control device 3, and an anti-blow-by gas medium storage bin 4. The sensing device includes an air pressure sensor 6, which is located on the casing of the screw feeder 1 and behind the inlet of the anti-blow-by gas medium. The distance between the inlet of the anti-channeling gas medium and the material outlet of the screw feeder is 3 times of the pitch of the screw blade. The anti-blow-by gas medium inlet is connected with the anti-blow-by gas medium storage bin 4 above it throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com