Hydraulic pressing tool for machining elbow bevel

A groove processing and hydraulic technology, which is applied to metal processing equipment, metal processing machine parts, positioning devices, etc., can solve the problems of high labor intensity, low production efficiency, and long working hours for operators, and achieve simple structure and high working efficiency. The effect of improving efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

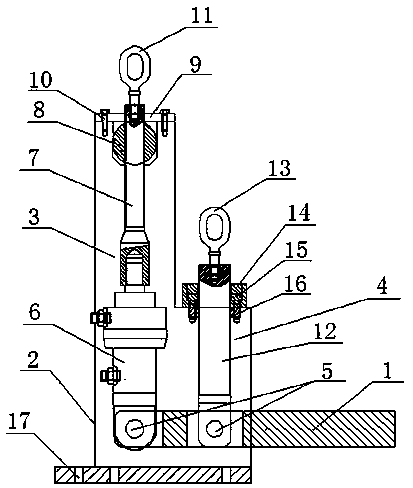

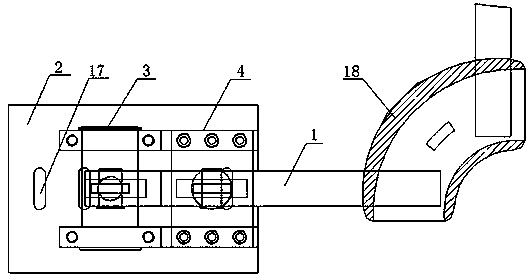

[0019] refer to Figure 1-Figure 2 , the hydraulic pressure tooling for elbow bevel processing in this embodiment includes a pressure plate 1, a support seat 2, a hydraulic mechanism 3 and a support mechanism 4, one end of the pressure plate 1 is arranged in the support seat 2, and the hydraulic mechanism 3 The bottom end and the bottom end of the support mechanism 4 are respectively movably connected with the pressure plate 1 extending into the support seat 2 through cylindrical pins 5; 10 and a lifting chain link 11, the working end of the oil cylinder 6 is screwed firmly connected with one end of the oil cylinder adjusting screw rod 7 to form a whole that runs through the inside of the support seat 2, and the other end of the oil cylinder adjusting screw rod 7 extends out of the support seat 2, and screwed The lifting chain ring 11 is fixedly connected, the nut pin 8 is set in the top groove of the support seat 2 and is threadedly connected with the oil cylinder adjustment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com