Method and system for measuring battery plate surface density based on capacitive transducer

A technology of capacitive sensor and density measurement, which is applied in the direction of electric/magnetic thickness measurement, electromagnetic measuring device, and device for coating liquid on the surface, etc. It can solve the problems of increased production cost, large hysteresis, waste of materials, etc., and achieve production efficiency The effect of improving, improving consistency, and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is described in detail below in conjunction with accompanying drawing:

[0038] The surface density of the polar piece is the mass of the positive piece per unit surface, with ρ 面 to express, that is, the formula:

[0039]

[0040] In the formula: m is the mass, S is the area of the pole piece, V is the volume of the pole piece, and ρ is the density of the pole piece.

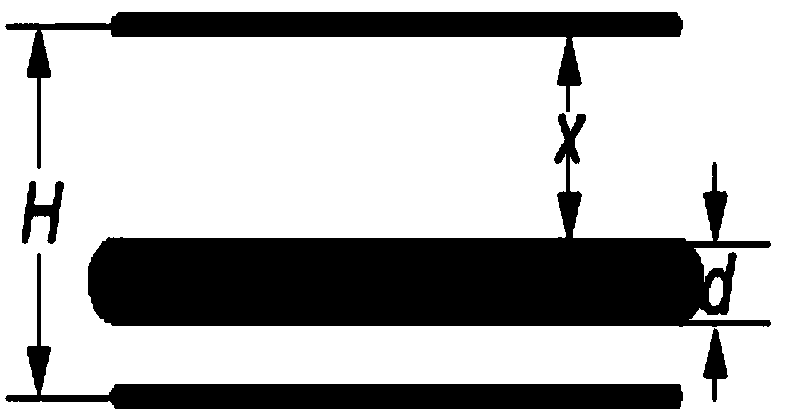

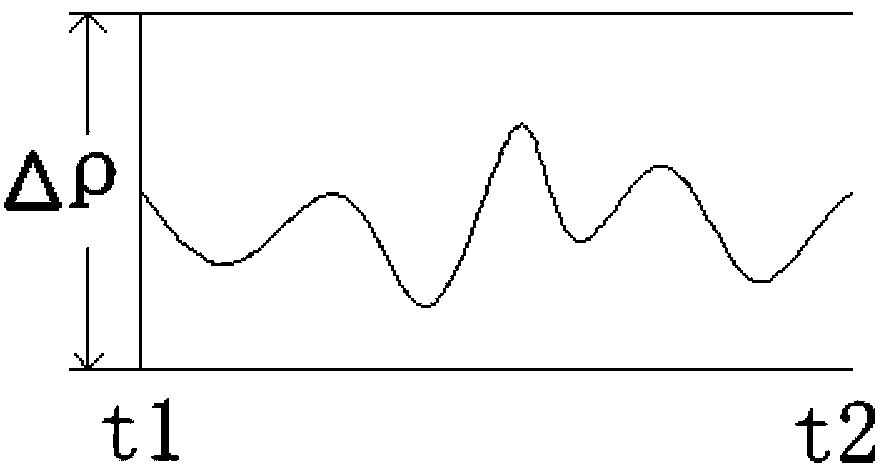

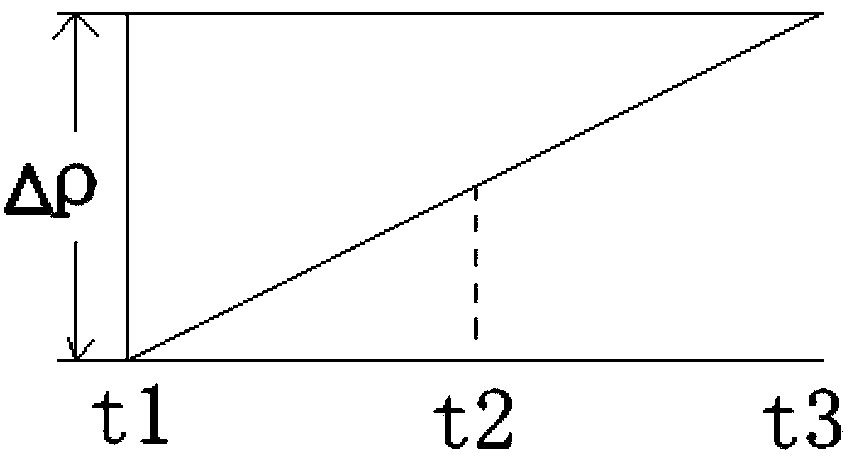

[0041] It can be seen from the formula that there is a proportional relationship between the surface density value and the thickness d of the pole piece and the density ρ of the pole piece material. It can be seen from the formula of the surface density value that the measurement of the surface density not only needs to measure the thickness d, but also measures the density ρ of the pole piece material, and the measurement of the capacitive sensor 5 in this system can meet the above requirements. The ideal model of the capacitive sensor 5 probe and the lower plate is a parall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com