Thermosetting cutting knife

A cutting knife and support tube technology, applied in the field of medical devices, can solve the problems of easy burnout of hot wires, small hinge size, scalding of intra-abdominal tissue, etc., and achieve the effects of preventing local resistance from increasing, stabilizing the holding force, and being convenient to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

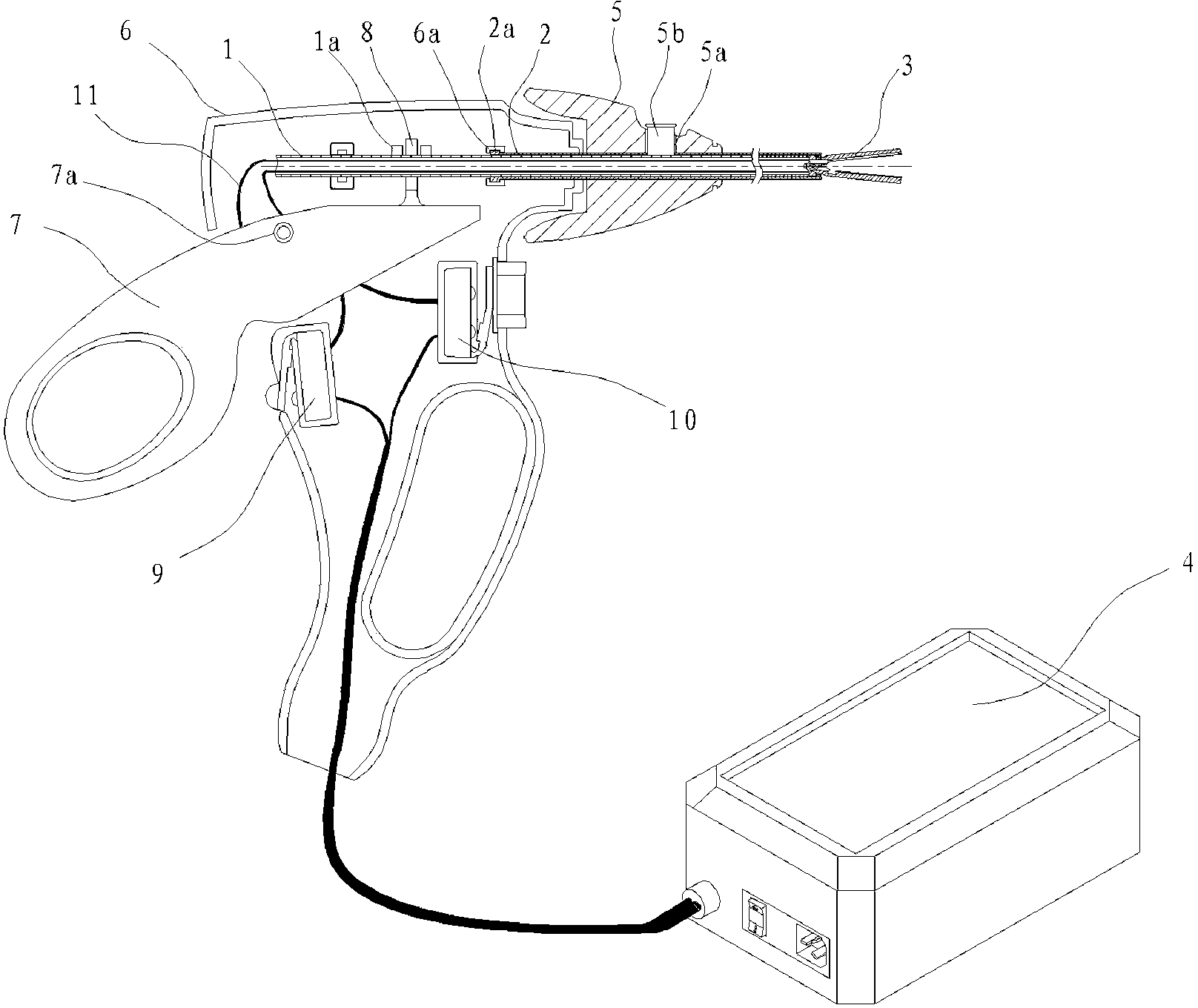

[0027] like figure 1 As shown, a thermocoagulation cutting knife provided by the present invention includes a casing 6, a wrench 7 is connected in the casing 6, the front end of the wrench 7 is connected to the support tube 1, and the front end of the support tube 1 is connected with the clamping claws 3 that cooperate with each other. , characterized by:

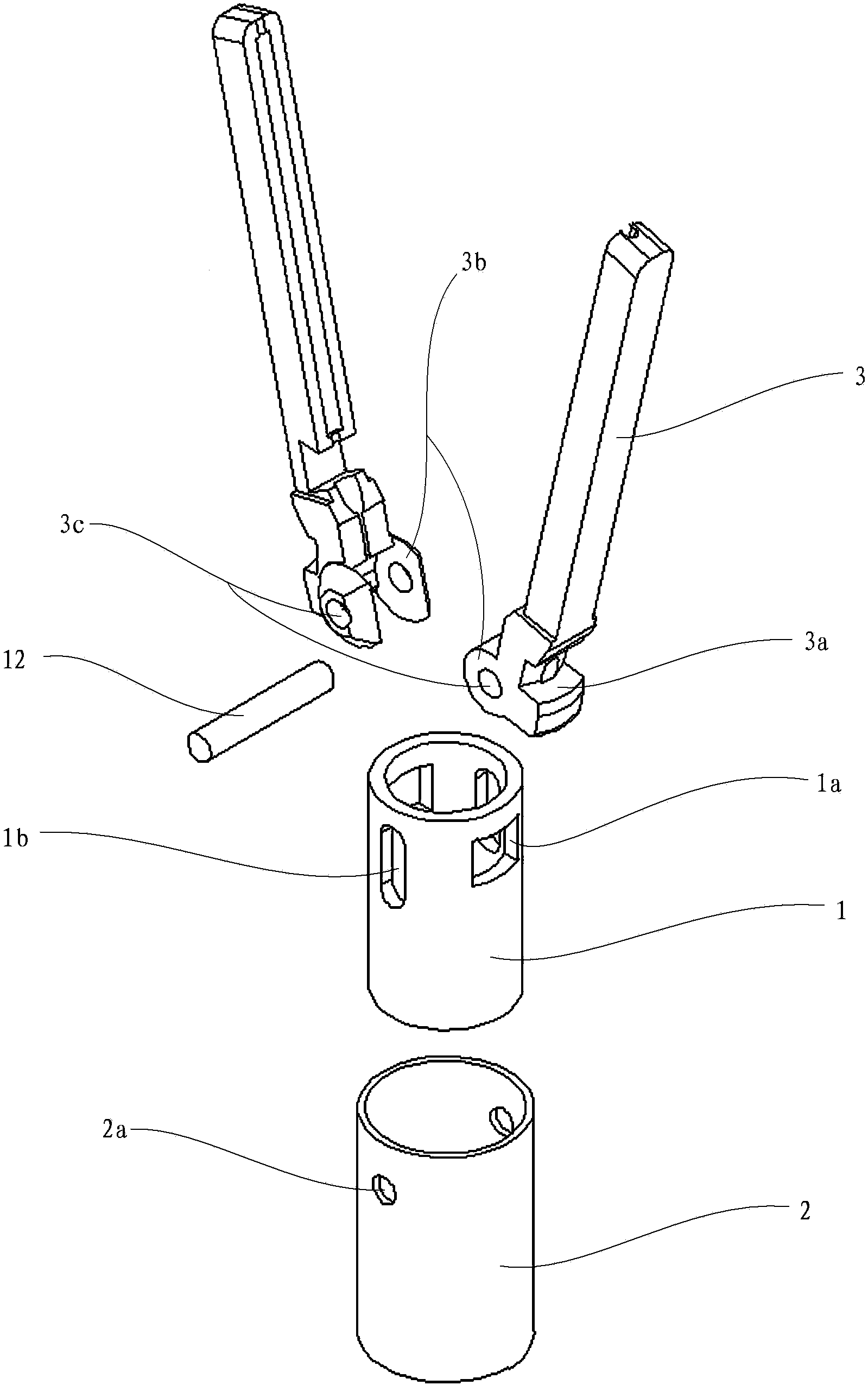

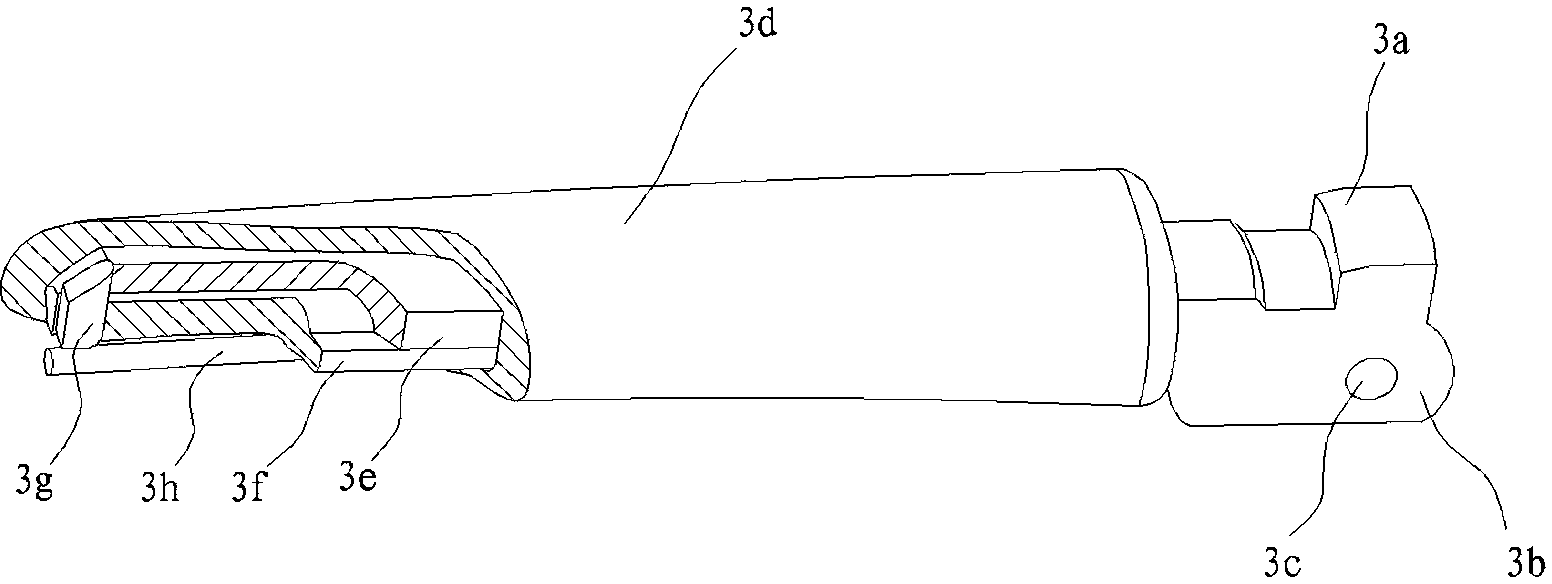

[0028] a. to combine figure 2 As shown, a section of outer tube 2 is sleeved on the support tube 1, and a flange 2a is provided at the rear end of the outer tube 2. There are two symmetrical square openings 1a, and two symmetrical rectangular chute 1b are also provided at the front end of the support tube 1, and the penetration lines of the two chute 1b and the penetration line of the overlapping opening 1a are perpendicular to each other , There are two symmetrical circular fixing holes 2a at the front end of the outer tube 2, each fixing hole 2a is matched with the corresponding chute 1b, and a square strap is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com