A multi-speed transmission transmission mechanism

A transmission mechanism and transmission technology, which is applied to transmissions, gear transmissions, mechanical equipment, etc., can solve problems such as unsatisfactory power and economy of automobiles, unfavorable structural layout design of automobiles, and large changes in engine speed. Achieve the effect of flexible structural layout design, economical ideal, and improved shifting smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example ( 7

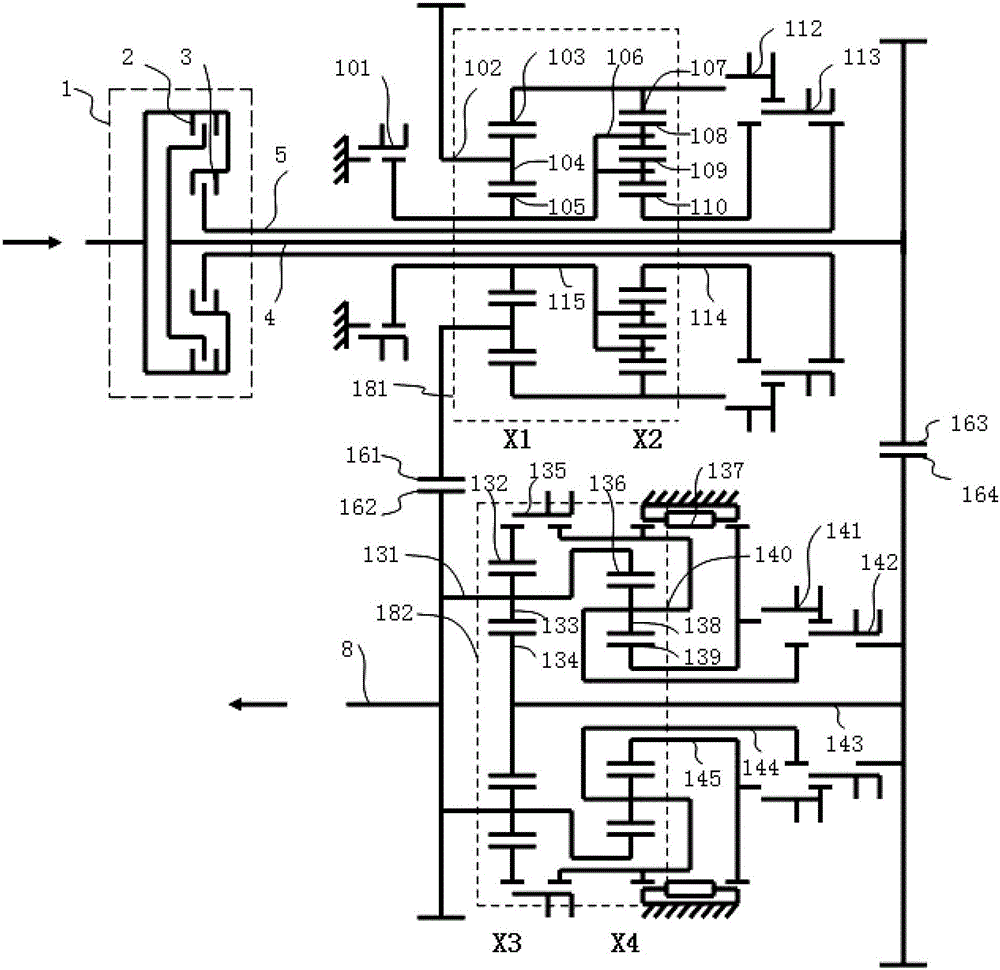

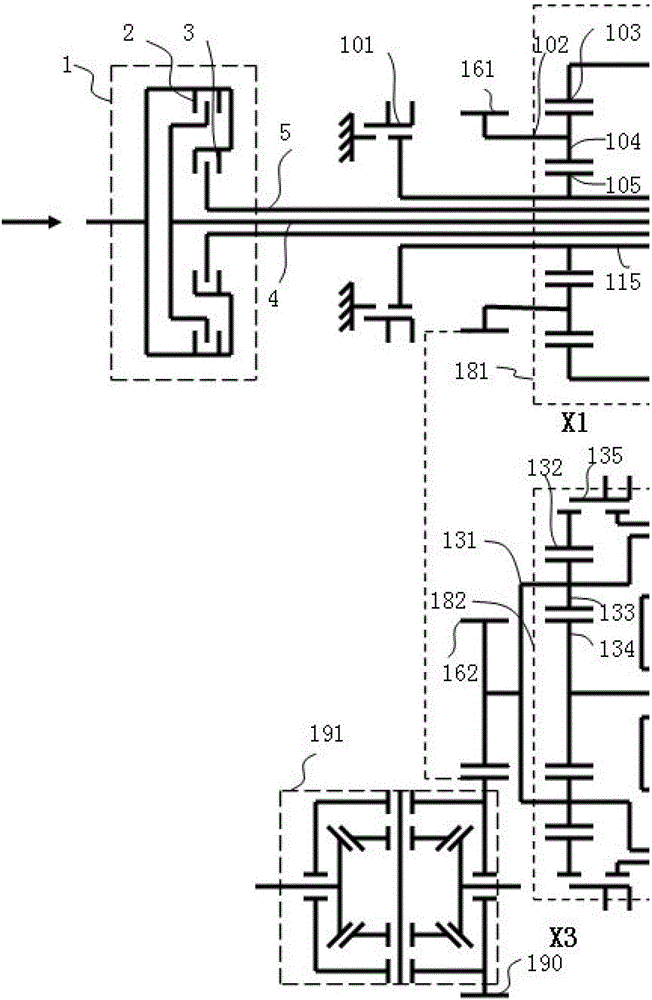

[0018] see figure 1 , the dual clutch of the present invention comprises a dual clutch assembly 1 (comprising a first clutch 2 and a second clutch 3, respectively corresponding to the first input shaft 4 and the second input shaft 5 of the two clutches, the first double-row planetary gear train 181, the second Two double-row planetary gear trains 182, output shaft 8 and multiple synchronizers. The first double-row planetary gear train and the second double-row planetary gear train are arranged in a vertical structure, and the first double-row planetary gear train adopts new double planetary gears Transmission mechanism, the second double-row planetary gear train adopts CR-CR gear transmission mechanism, the first double-row planetary gear train includes the first planetary row X1 and the second planetary row X2, and the second double-row planetary gear train includes the third planetary gear row X3 and the fourth planet row X4.

[0019] The front sun gear 105 and the rear pla...

no. 2 example ( 6

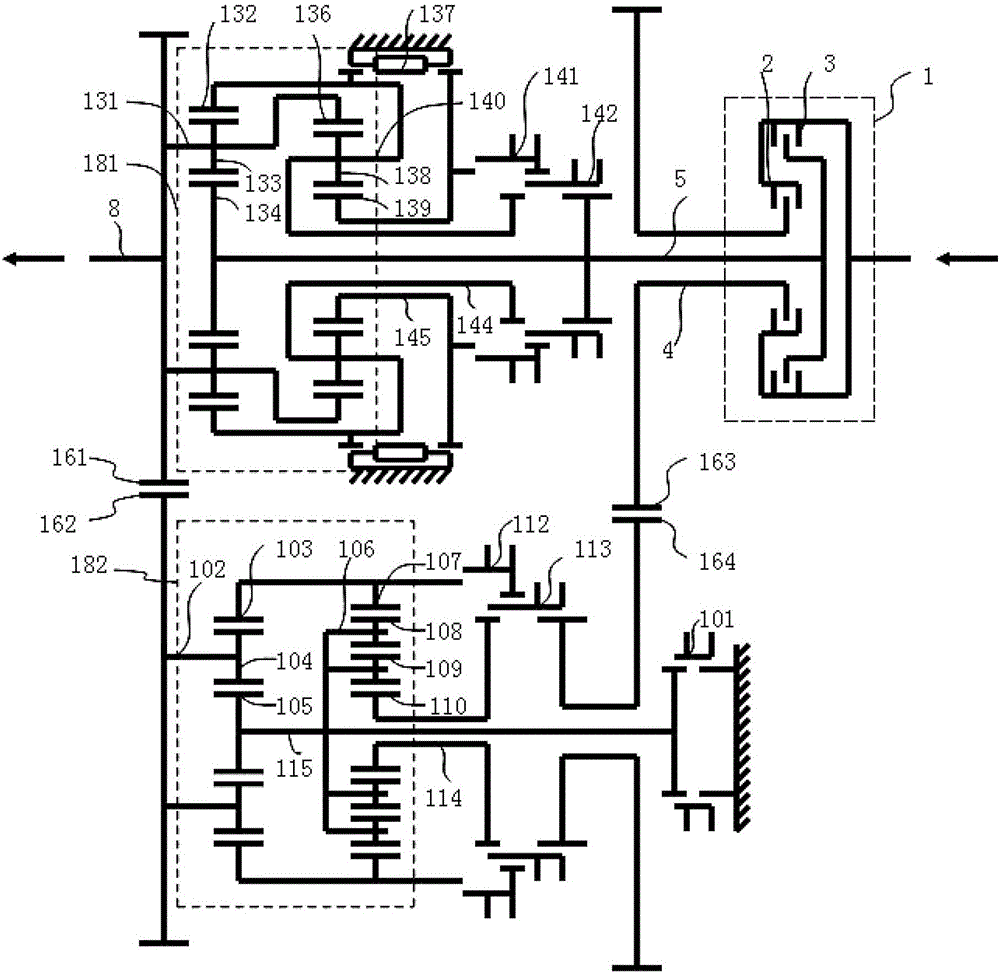

[0046] see figure 2 , on the basis of the first embodiment, the positions of the first double-row planetary gear train and the second double-row planetary gear train are interchanged, the second constant mesh synchronizer 135 is canceled, and the dual-clutch assembly 1 is set in the first double-row planetary gear train On the right side of the planetary gear train 181 , the output shaft 8 is arranged on the first double-row planetary gear train 181 on the same axis as the dual clutch assembly 1 but on a different side. According to the transmission ratio setting of gears, the transmission ratios of the first gear 161 and the second gear 162 , the third gear 163 and the fourth gear 164 , and the value a of each planetary row need to be appropriately changed. The first double-row planetary gear train 181 realizes 1.3.5 and reverse gears like this, and the second double-row planetary gear train 182 realizes 2.4.6 gears.

[0047] It can be known from the above embodiments that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com