Milling machine connection device

A connecting device and milling machine technology, which is applied to milling machine equipment, milling devices that can be installed on machine tools, large fixed members, etc., can solve the problems of low equipment performance and utilization rate, small equipment processing range, and high equipment cost. , to achieve the effects of widening equipment processing methods, compact structure, and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

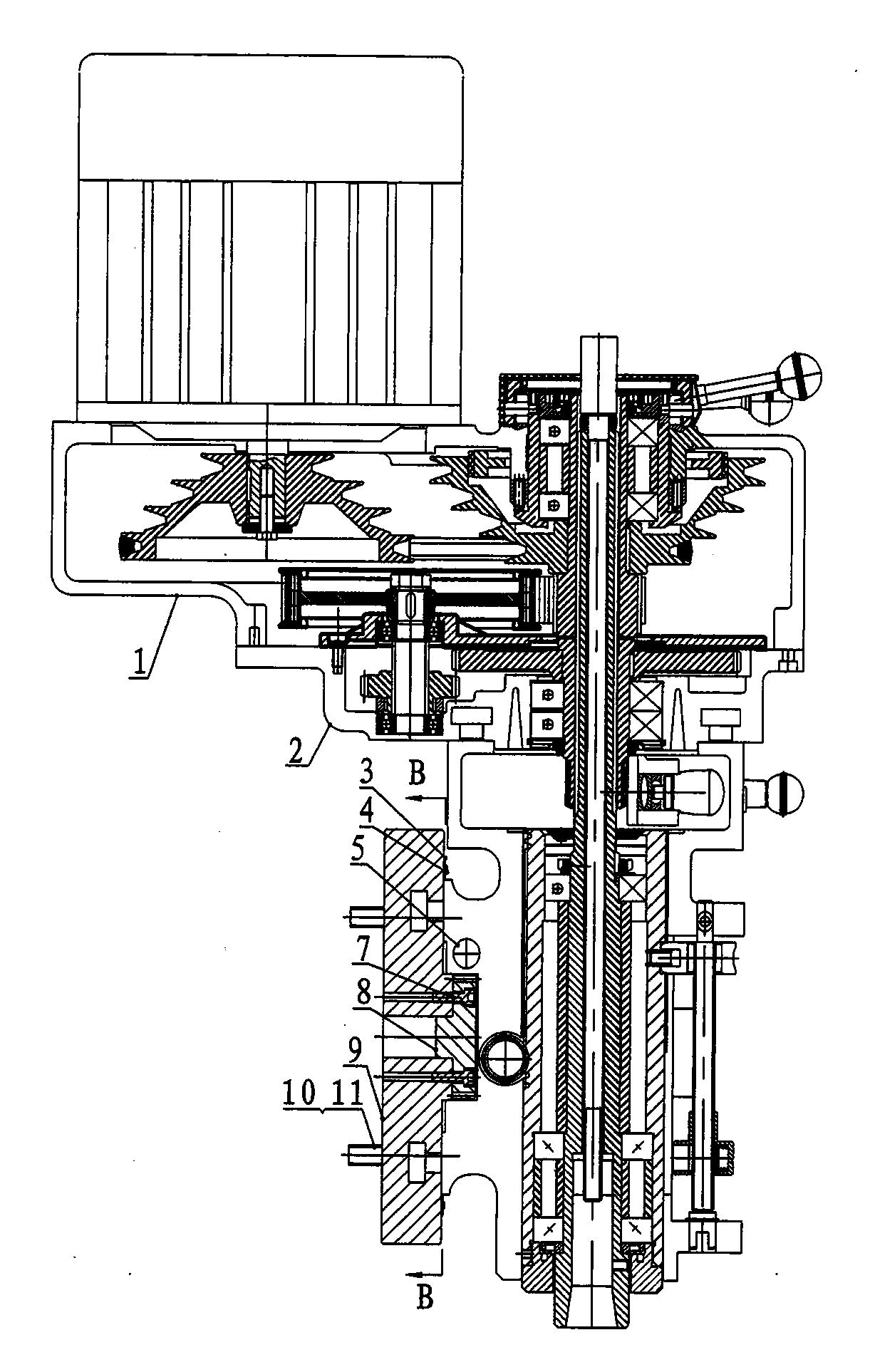

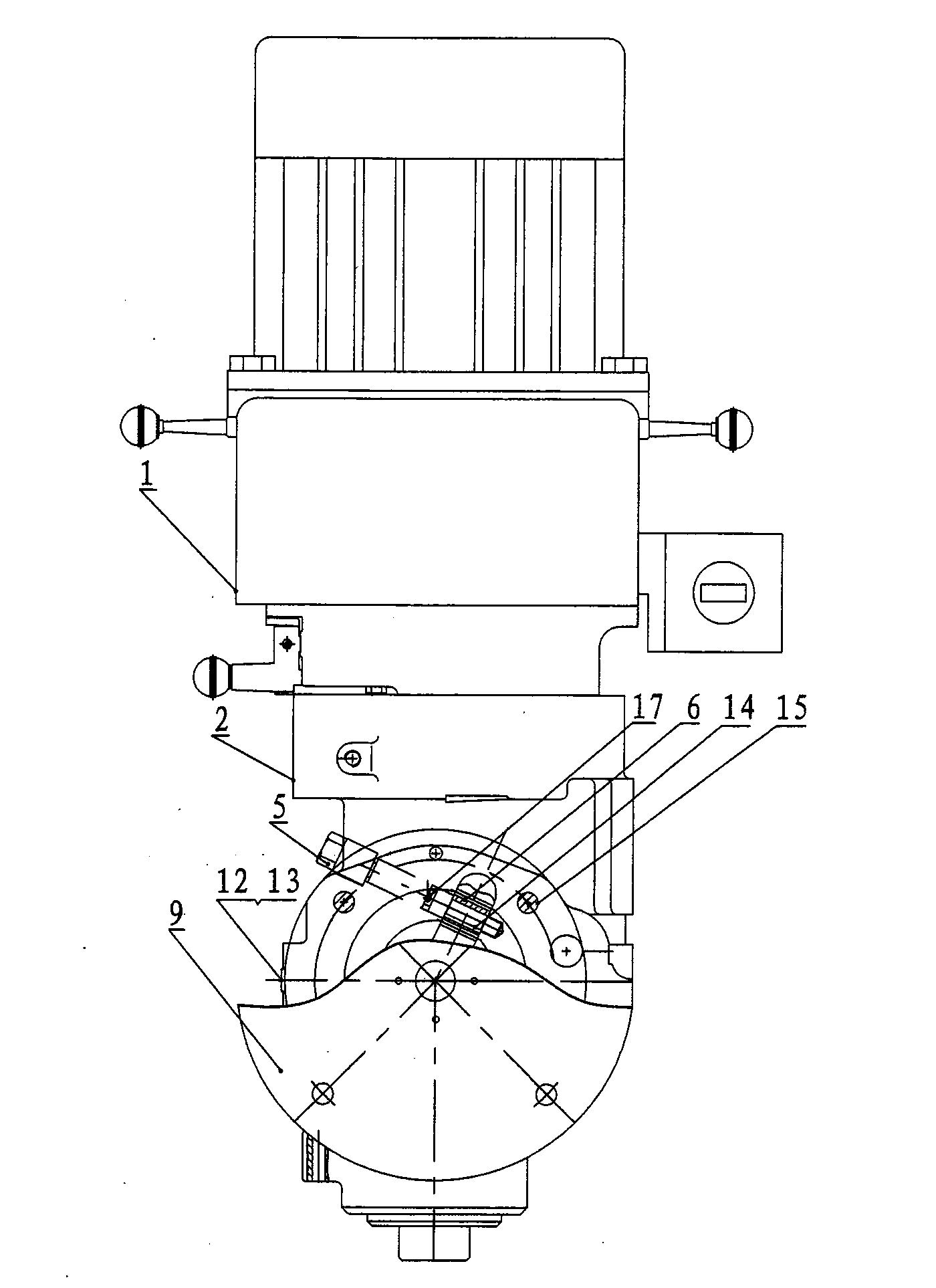

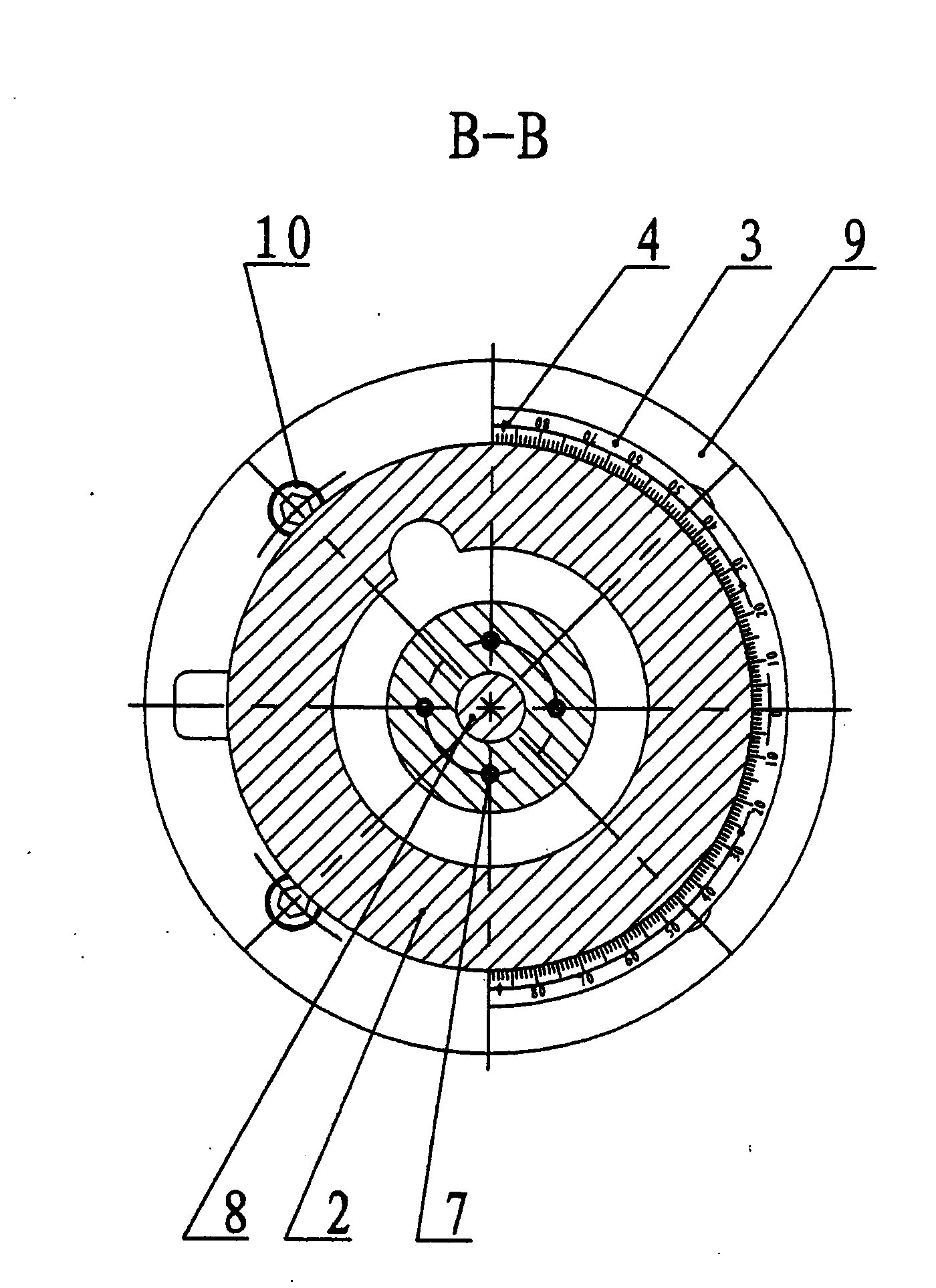

[0014] The preferred embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0015] A connection device for a vertical milling machine, which includes an end milling head 1, a connecting seat 9 connected to the end milling head body 2, an indexing helical gear 8 connected to the right middle part of the connecting seat 9, and a scale connected to the right side of the connecting seat 9 Disk 3, the worm axis 5 fixed on the end milling head body 2, the indexing worm 6 which is inserted into the worm axis 5 and meshed with the indexing helical gear 8, and fixed on the right side of the middle part of the end milling head body 2 Point to the indicator plate 12 at the "0" degree on the dial 3.

[0016] See attached figure 1 , figure 2 , image 3 , use the fastening screw 7 to fasten the indexing helical gear 8 on the connecting seat 9, use the mounting screw 4 to fasten the dial 3 on the connecting seat 9, use the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com