Flexible package container for solid fluid and clamp assembly thereof

A technology of solid fluid and flexible packaging, which is applied in the direction of containers, packaging, flexible containers, etc., which can solve the problems that quantitative access cannot be realized, and stable flow channels or temporary storage chambers cannot be formed, so as to maintain space utilization and reliable fluid volume Take, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

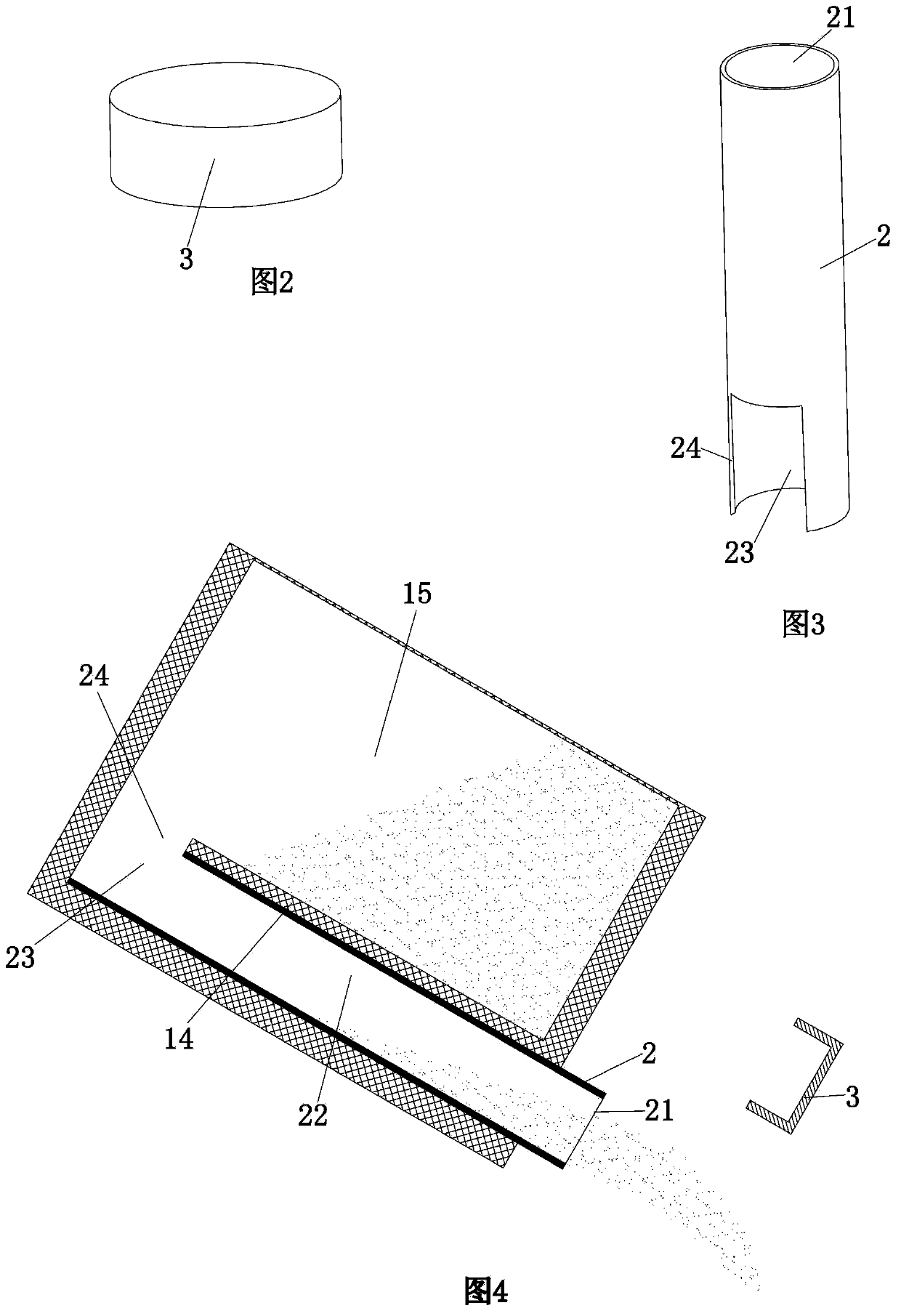

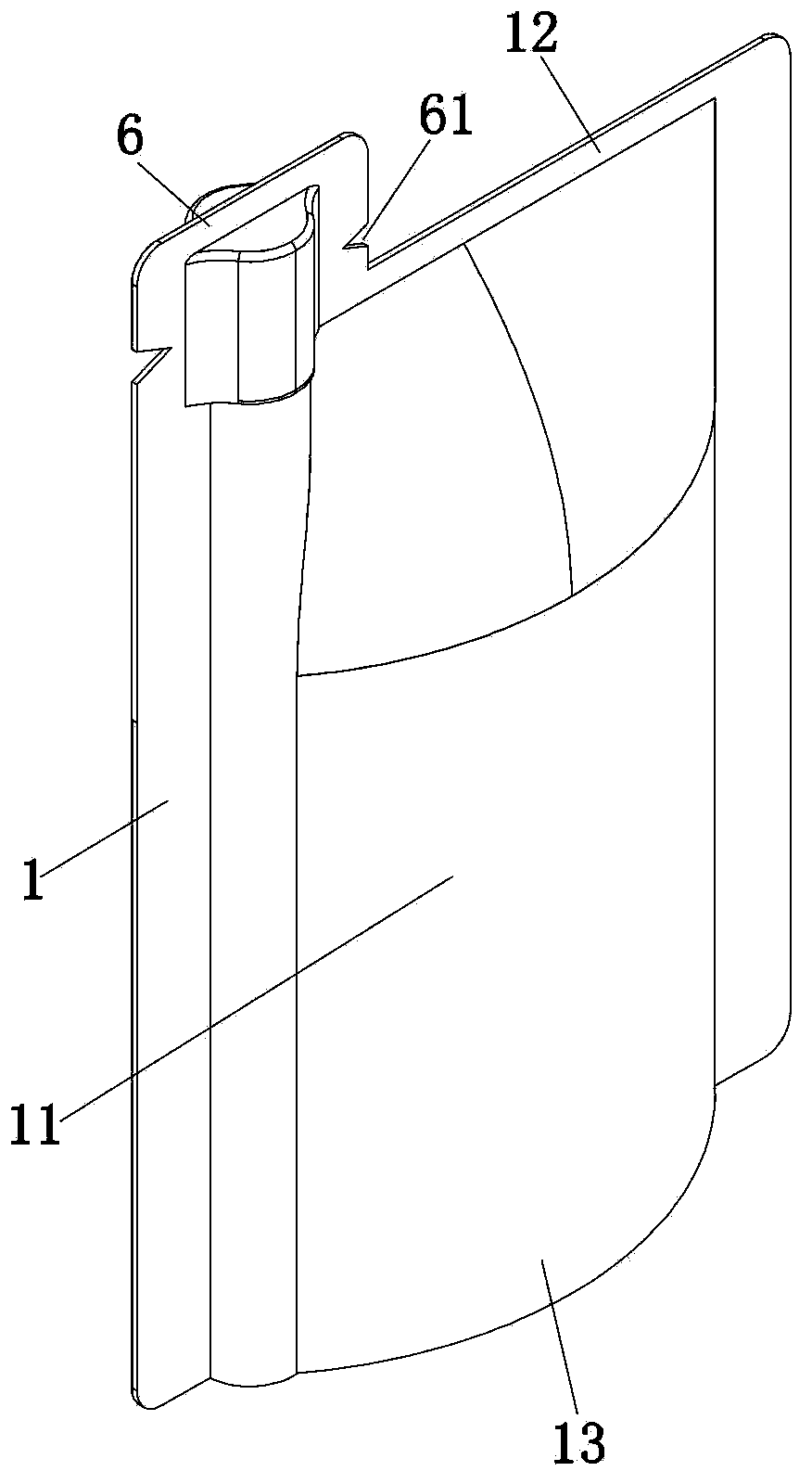

[0075] Such as Figure 1 to Figure 4 Shown, it is the first embodiment of flexible packaging container. The flexible packaging container includes a main body 1 , a hard support tube 2 and a closing body 3 . The main body 1 includes a surrounding wall 11 , a top sealing edge 12 closing the top end of the surrounding wall, and a bottom edge 13 closing the bottom end of the surrounding wall. The peripheral wall 11 has a vertical barrier line 14, the top of the barrier line 14 is connected to the top edge 12, the bottom end of the barrier line 14 extends to the bottom edge 13 and is located above the bottom edge 13, the barrier line 14 connects the main body The interior is divided into left and right parts. The support tube 2 is a tubular body that penetrates up and down, is located inside the main body and is fixed to the peripheral wall 11 of the main body. The upper part of the support tube 2 is fixed to the top edge 12 of the main body, and the lower part of the support tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com