Quick mold changing device, injection molding machine, and quick mold changing method for injection molding machine

An injection molding machine, fast technology, applied in the field of quick mold change, can solve the problem of reducing the time of fastening bolts, etc., and achieve the effect of improving the efficiency of mold change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

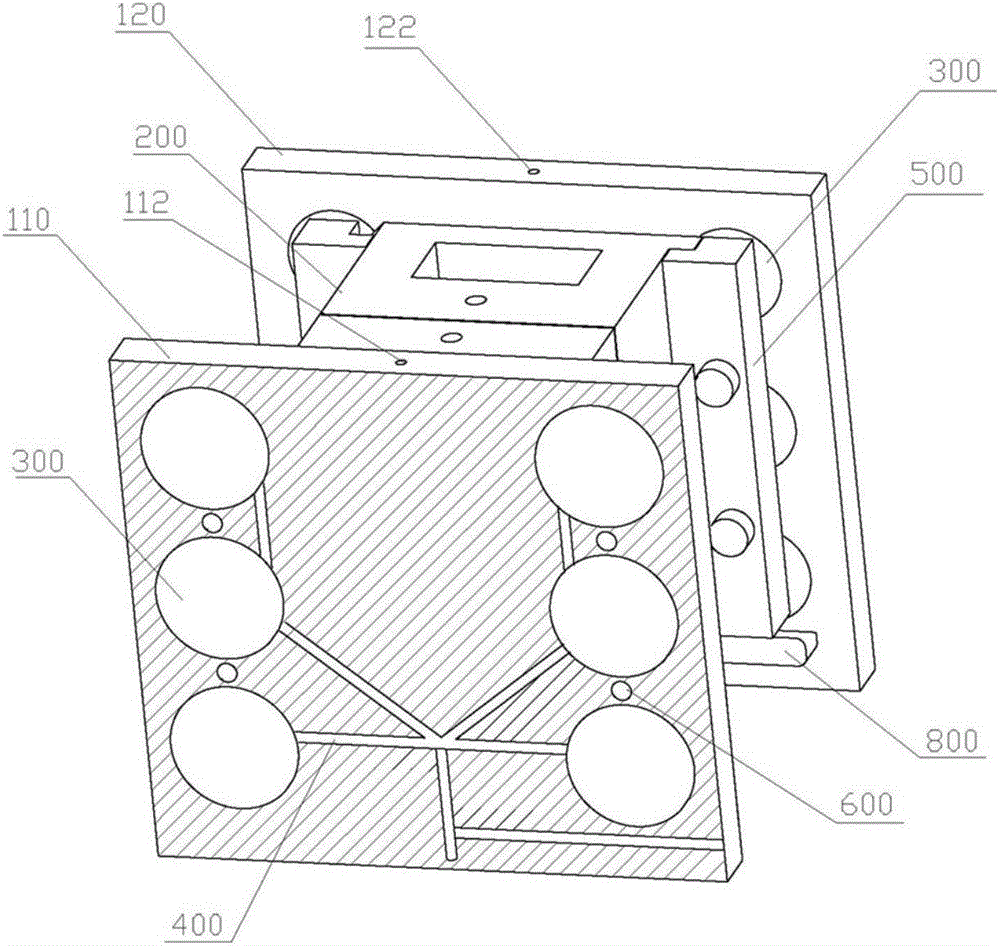

[0042] like figure 1 As shown, the mold loading tooling in this embodiment includes two mold backing plates for clamping the mould, which are respectively a front mold backing plate 110 and a rear mold backing plate 120, and the mold 200 is loaded on the two mold backing plates 110 , 120, the two mold backing plates 110, 120 are provided with a pneumatic device that can fix or unfix the mold 200 on the plate body.

[0043] Preferably, the pneumatic device includes a pneumatic chuck 300 and a chuck air passage 400 communicating with it for introducing gas, such as figure 2 Shown; Pneumatic chuck 300 is respectively placed on the plate body of mold backing plate 110,120;

[0044] Pneumatic chuck 300 is a standard part, which penetrates and is arranged on the plate body of formwork backing plate 110, 120, and its inner end surface is provided with a horizontal drag hook located between two formwork backing plates 110, 120; use standard pneumatic chuck 300 , easy to design and ...

Embodiment 2

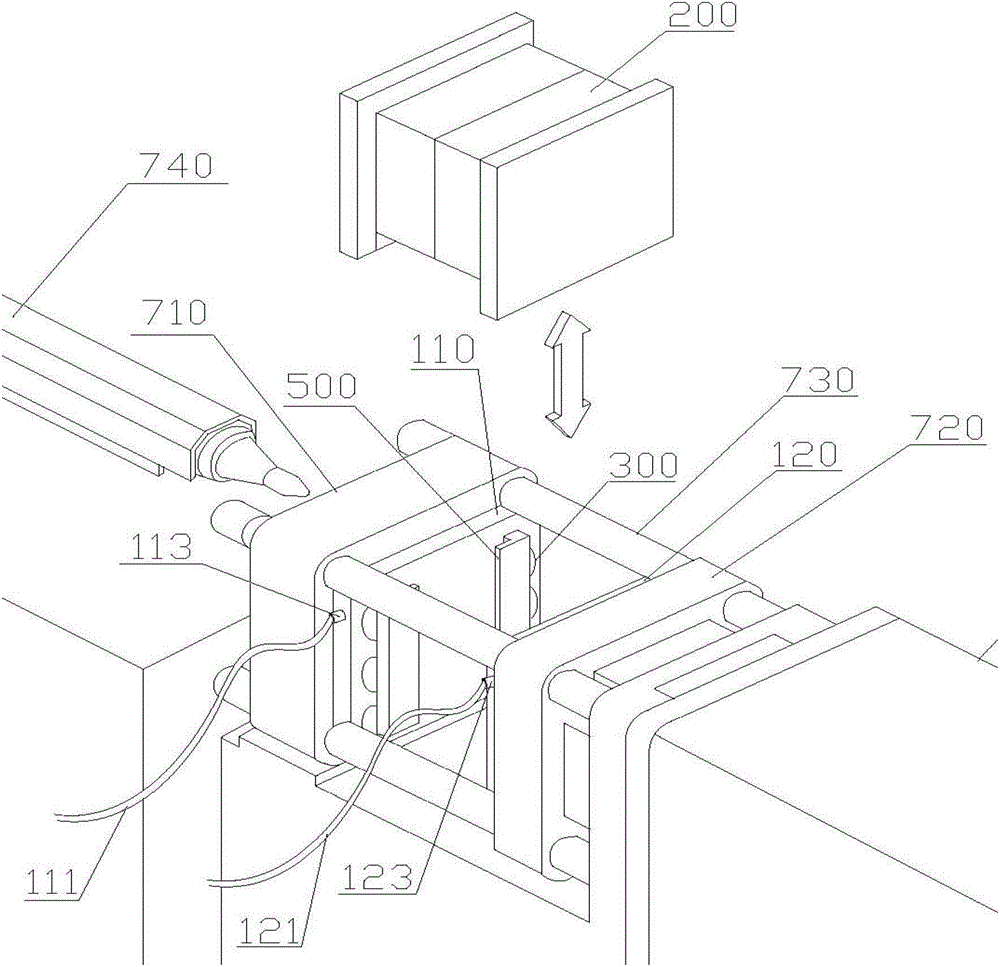

[0049] like figure 2 As shown, the injection molding machine in this embodiment includes a front size template 710 and a rear size template 720, and four guide positioning columns 730 are arranged between the front size template 710 and the rear size template 720; the injection molding machine also includes the first embodiment. The quick mold changing device and the high-pressure air pipes 111, 121 for inputting high-pressure gas;

[0050] The output ends of the high-pressure air pipes 111, 121 respectively penetrate into the plates of the two mold backing plates 110, 120 of the mold loading tooling, and communicate with the chuck air passage 400;

[0051] The two mold backing plates 110, 120 of the quick mold changing device are respectively fixed on the inner sides of the front and rear code templates 710, 720 of the injection molding machine.

[0052] Preferably, the two mold support plates 110, 120 of the quick mold change device are smaller than the front and rear code t...

Embodiment 3

[0057] The quick mold change method of the injection molding machine in this embodiment uses the injection molding machine in Embodiment 2; wherein, the injection molding machine also includes a mold ejector rod and a heating nozzle console 740;

[0058] The method includes the steps of dismantling old molds and loading new molds;

[0059] Wherein, the content of the operation of described loading new mold comprises:

[0060] Slowly open the front and rear mold plates 710 and 720 of the injection molding machine, adjust the position of the ejector rod of the injection molding machine to return, and withdraw the heating nozzle console 740 of the injection molding machine from the front mold plate 710, the push-out distance is 15 to 20 mm; the new mold is hoisted between the mold backing plates 110, 120 fixed on the inside of the front and rear code templates 710, 720; The joints 113 and 123 are connected, and the high-pressure gas is input to the pneumatic chuck 300 through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com