A frame structure of a car-carrying disc lifting device

A technology of lifting device and car-carrying tray, which is applied in the direction of buildings, building types, buildings, etc. where cars are parked, and can solve the problem of unfavorable overall rigidity and geometric accuracy of the lifting frame body, difficult control of geometric dimensions and shape and position tolerances, and affecting lifting loads. To improve product quality and operational stability, overcome static and dynamic geometric deformation, and improve the accuracy of overall geometric dimensions and shape and position tolerances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings.

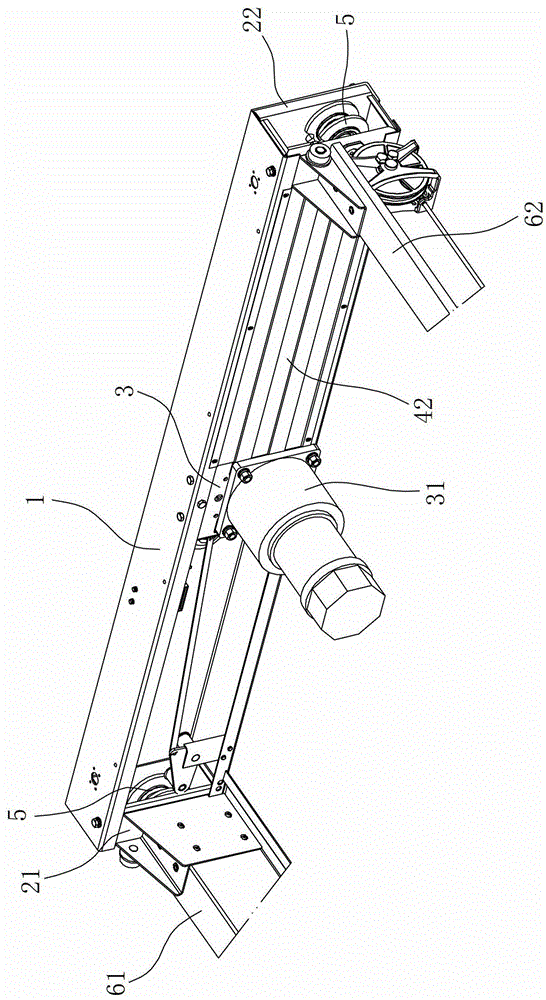

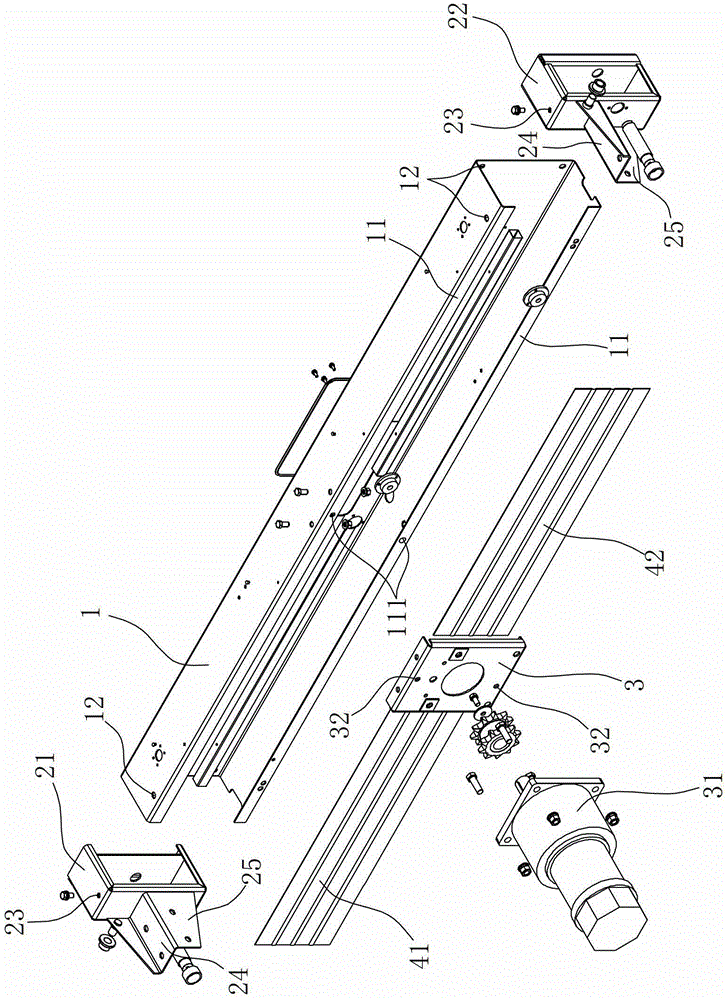

[0018] Such as Figure 1 ~ Figure 2 As shown, this embodiment discloses a frame structure of a vehicle-carrying disc lifting device, the frame structure includes a main beam 1 and a left box frame 21 and a right box frame 22 arranged on both sides of the main beam 1 .

[0019] Wherein, the main girder 1 is an integral part formed by bending and forming a steel plate. The cross section of the main girder 1 is U-shaped. The lifting mechanism (not shown in the figure), the main beam 1 is vertically bent and formed on the edge of the U-shaped opening to form opposite flanges 11, the flanges 11 are provided with mounting holes 111, and the mounting plate 3 is provided with There is a through hole 32 corresponding to the mounting hole 111, and the mounting plate 3 is fixedly arranged on the main beam 1 through a fastener (such as a screw, a bolt, or a pin shaft, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com