Non-welded car frame

A technology without welding and car frames, which is applied to elevators, transportation and packaging in buildings to avoid gas and light pollution, reduce logistics costs and prolong life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention are described in detail below:

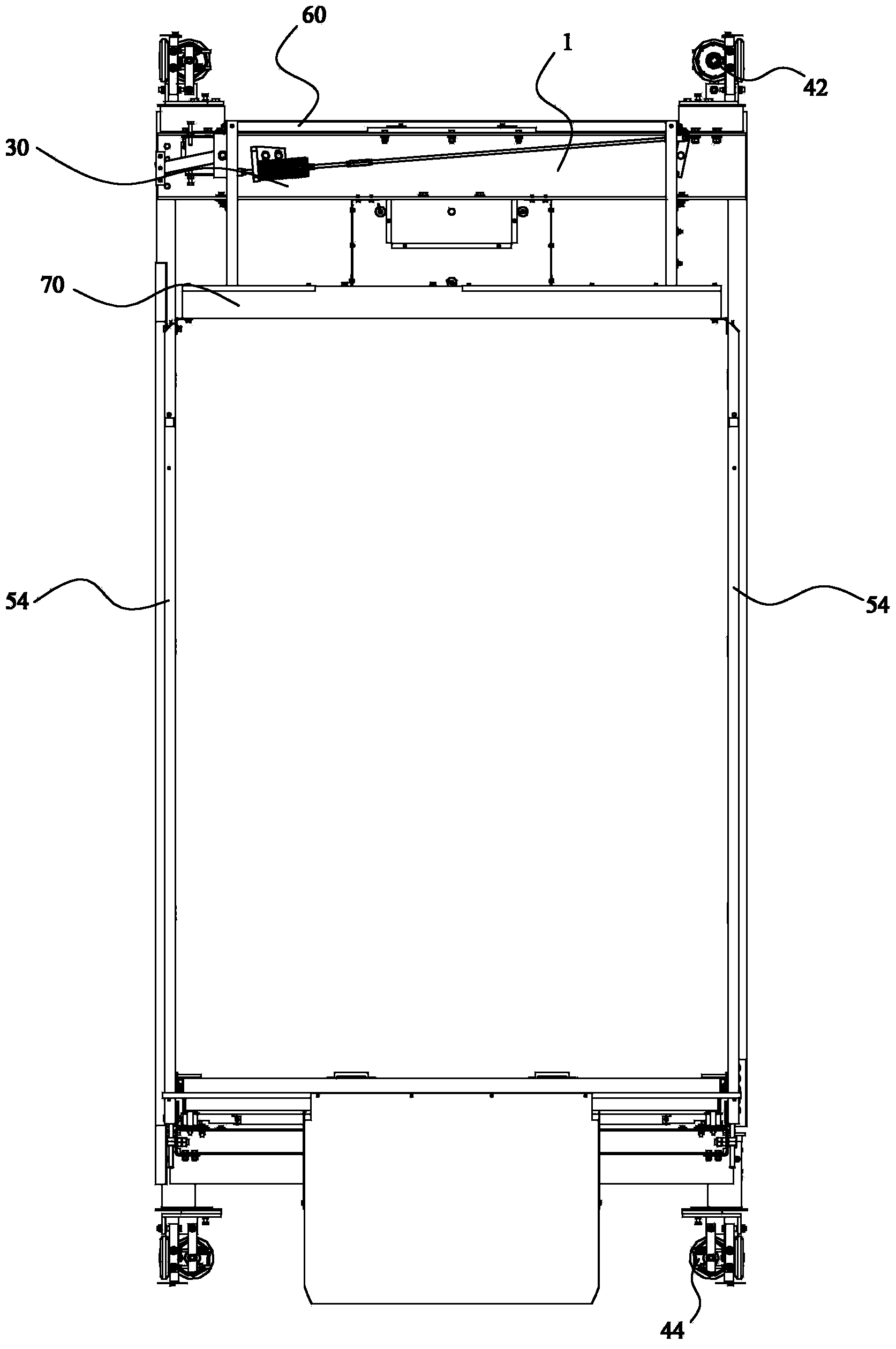

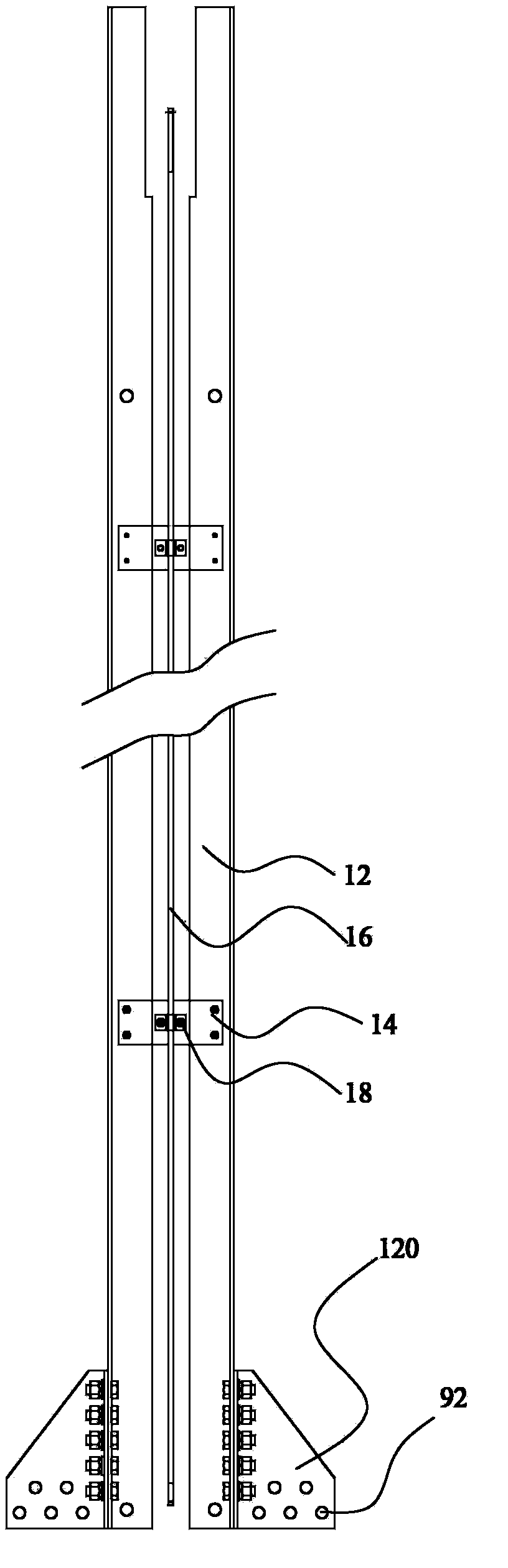

[0028] Such as Figure 1-2 The non-welded car frame 1 shown is a single-opening middle door car frame, which includes a column assembly 10 , a car floor assembly 20 , an upper beam assembly 30 and a guide shoe assembly 40 . In this embodiment, the guide shoe assembly 40 includes a first guide shoe assembly 42 and a second guide shoe assembly 44 . The non-welded car frame 1 also includes a plurality of fixing pieces 90 . The column assembly 10 has a plurality of first assembly parts 92 . The car floor assembly 20 , the upper beam assembly 30 , and the guide shoe assembly 40 each have a second assembly portion 94 . The plurality of fixing members 90 can assemble the car floor assembly 20 , the upper beam assembly 30 and the guide shoe assembly 40 on the column assembly 10 by correspondingly fixing the first assembly portion 92 and the second assembly portion 94 . It can be understood that the non-w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com