Conductive connecting body structure of connector

A conductive connection and connector technology, applied in the field of conductive connector structure, can solve the problems of insufficient clamping force, high manufacturing cost, copper wire falling off, etc., and achieve stable clamping force, low implementation cost, simple, reasonable and compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

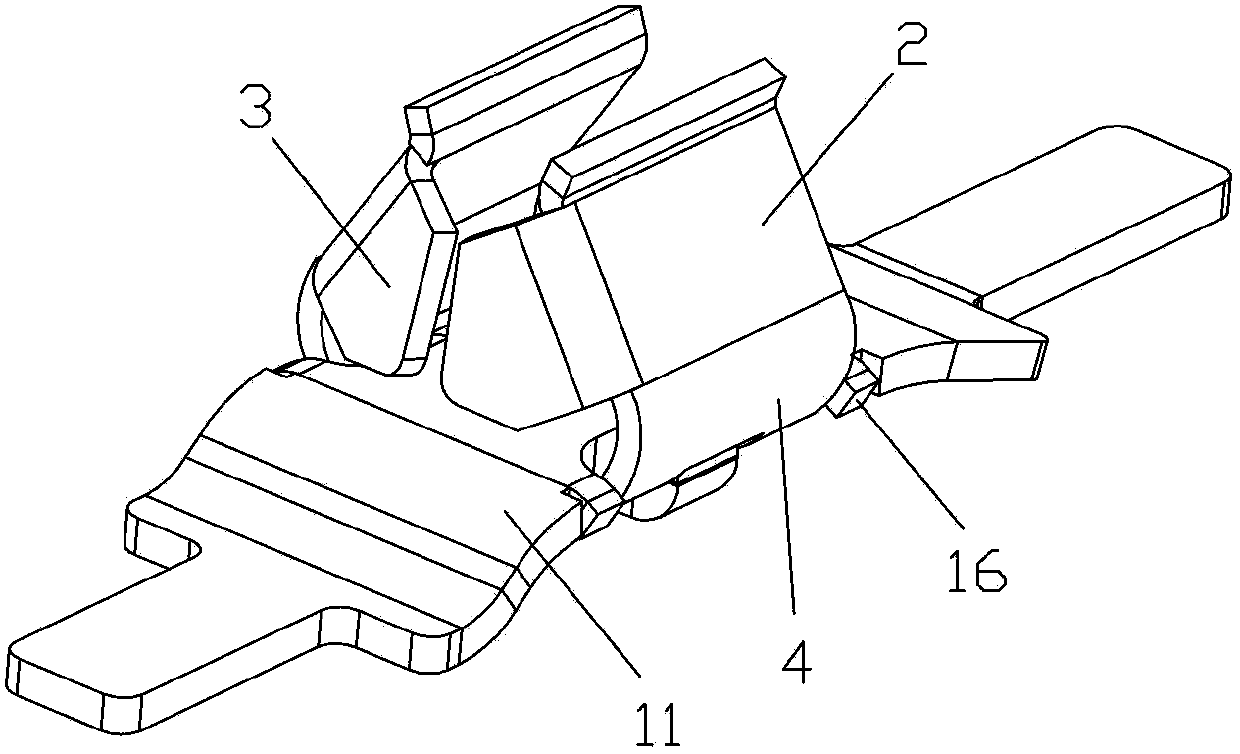

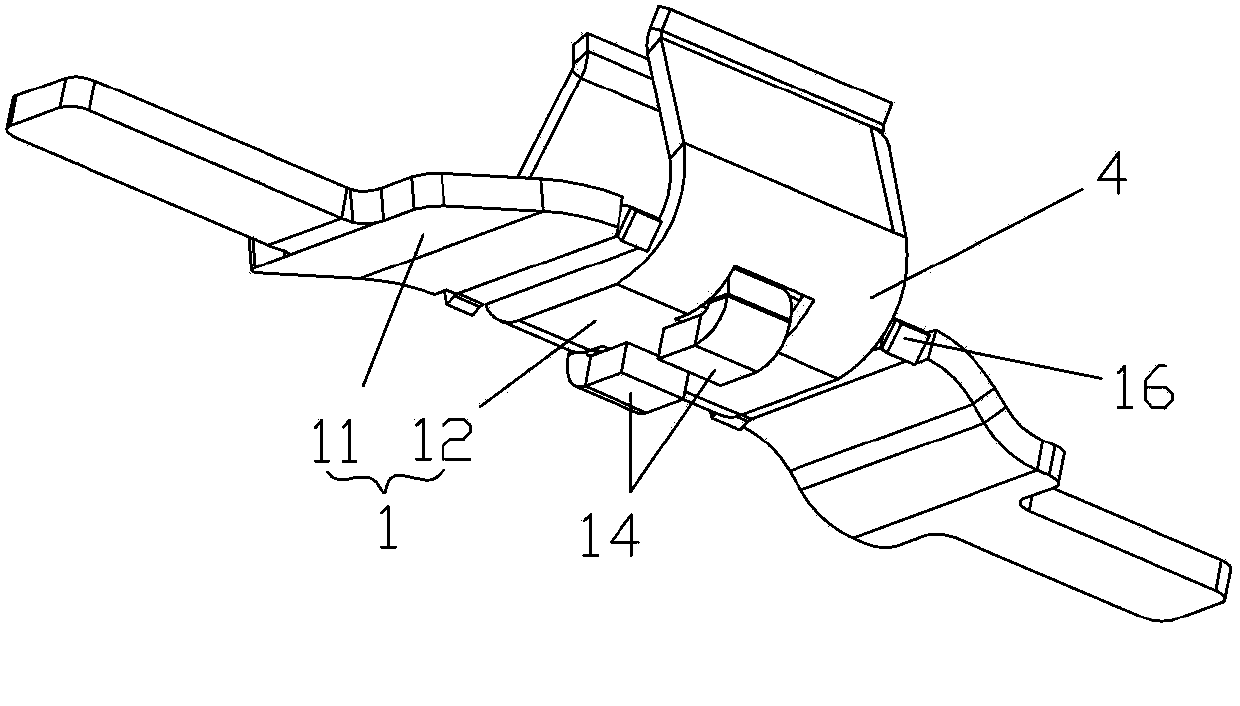

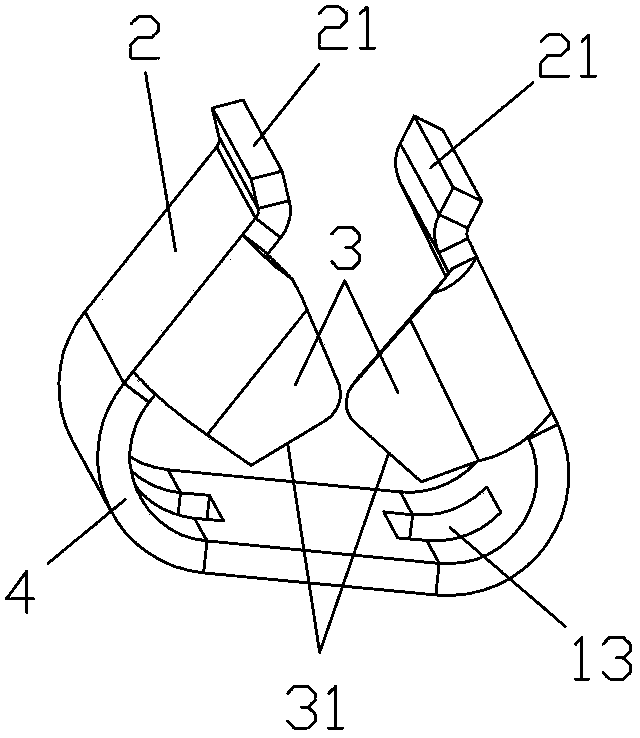

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0026] refer to Figure 1~Figure 11 , the conductive connector structure of the connector of the present invention includes a connecting body 1, and elastic clamping edges 2 are provided on opposite sides of the connecting body 1, and the elastic clamping edges 2 can be integrally formed on the connecting body 1, and the two The above-mentioned elastic clamping sides 2 are configured in a way that moves upward and closer together, so that the pressure block 53 on the connector housing 5 can easily push back the two elastic clamping sides 2, and the elastic clamping sides 2 can produce sufficient elastic reset after being pushed apart force, the elastic clip edge 2 is provided with a block 3, the block 3 can be integrally formed or welded on the elastic clip edge 2, the block 3 is provided with a bevel 31 or a gap 32 for clamping the wire 6, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com