Photovoltaic junction box

A technology of a volt junction box and a box body is applied in the field of photovoltaic junction boxes, which can solve the problems of scattered core wires, difficulty in threading, and inability to fully penetrate the cable slot, etc., and achieves the effect of improving assembly efficiency and facilitating installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

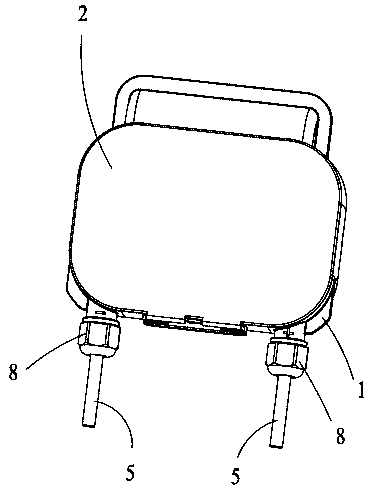

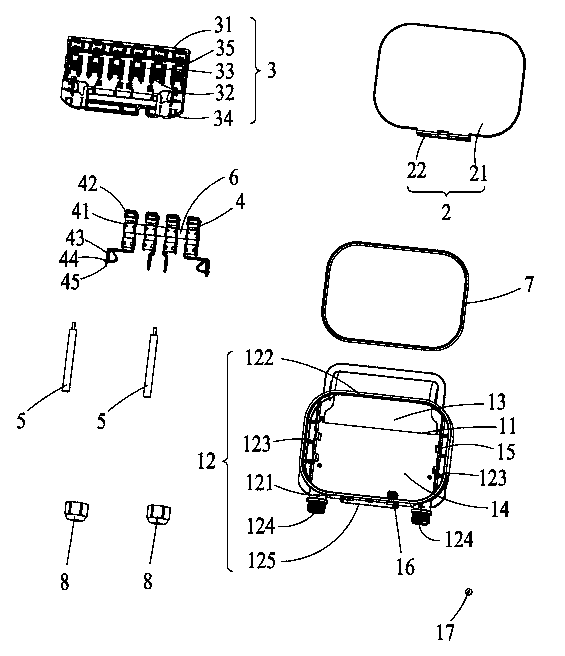

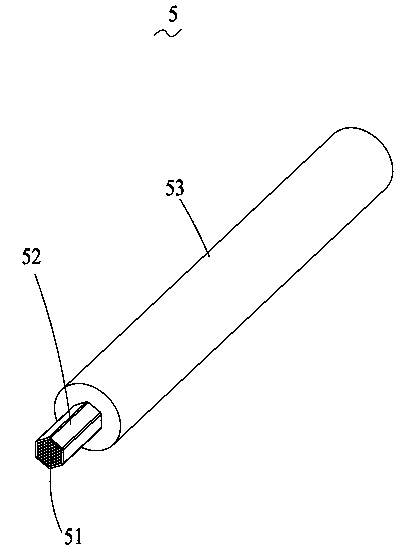

[0021] See figure 1 , 2 4. A photovoltaic junction box according to an embodiment of the present invention includes a box body 1, a box cover 2 matched with the box body 1, a terminal fixing member 3 and a terminal 4 installed in the box body 1, and a terminal 4 electrically connected to the box body 1 respectively. Connected bus strips (not shown), cables 5 and diodes 6. The box body 1 includes a mounting portion 11 , a side portion 12 extending upward from the mounting portion 11 , an opening portion 13 passing through the mounting portion 11 to realize the electrical connection between the busbar and the terminal 4 , and the mounting portion 11 and the side portion 12 . The above-mentioned terminal 4 is fixed on the terminal fixing member 3 , and the terminal fixing member 3 is fixed in the cavity 14 . The side portion 12 includes a rear wall 121, a front wall 122 opposite to the rear wall 121, two side walls 123 connecting the front wall 122 and the rear wall 121, penetr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com