Separated type weight balancing device

A counterweight device and separate technology, which is applied in the field of separate weight counterweight devices, can solve the problems of difficult to ensure the mass balance of the counterweight, difficulty, difficulty in installation and transportation, etc., and achieve convenient and fast weight coordination and mass balance rate Improvement, the effect that is convenient for adjustment of the weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

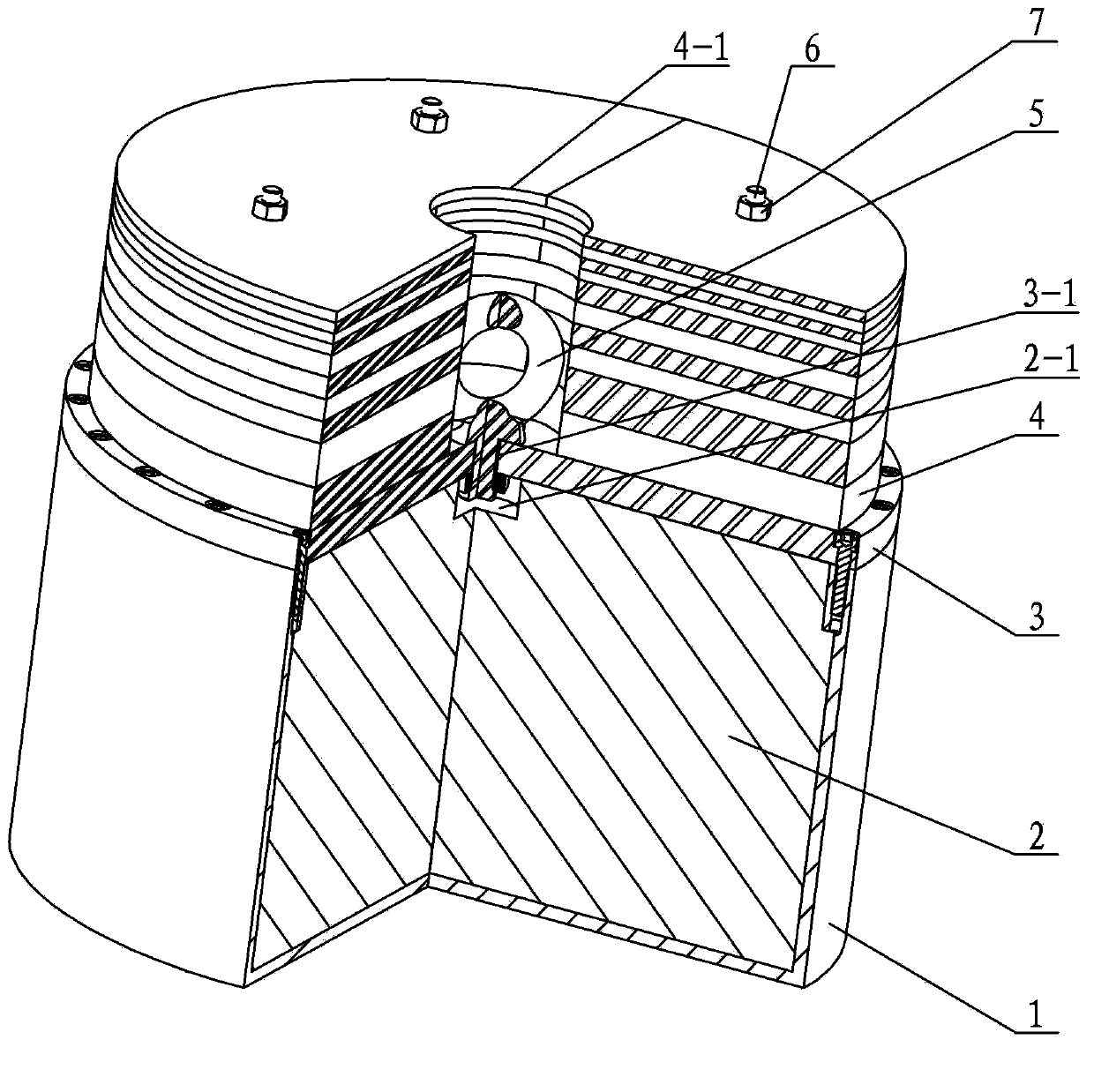

[0011] Specific implementation mode one: combine figure 1 with figure 2 Describe this embodiment, this embodiment includes counterweight container 1, counterweight lead core 2, counterweight container cover 3, eyebolt screw 5, four fixing studs 6, four fixing nuts 7 and several counterweight weights 4 , the counterweight lead core 2 is installed in the counterweight container 1, the counterweight container cover 3 is installed on the upper end of the counterweight lead core 2 and fixed with the counterweight container 1 with connecting elements, and several counterweight weights 4 are stacked sequentially from bottom to top Placed on the upper end of the counterweight lead core 2, four fixed studs 6 are evenly distributed on the upper end surface of the counterweight container cover 3 along the same circumference, and the lower end of each fixed stud 6 is threadedly connected with the counterweight container cover 3. The upper end of a fixed stud 6 passes through several cou...

specific Embodiment approach 2

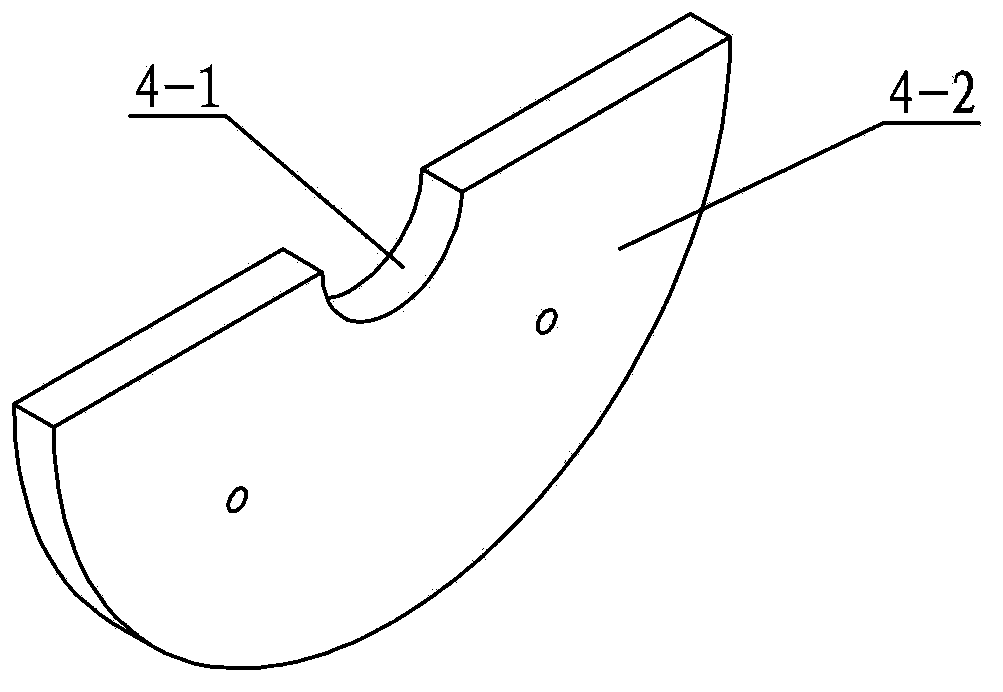

[0012] Specific implementation mode two: combination figure 1 This embodiment is described. In this embodiment, two groups of semicircular counterweights 4 are formed into a complete circle with the eye screw 5 as the center, and are stacked on the upper end surface of the counterweight container cover 3. Each The semicircular joints of the counter weights 4 of two adjacent layers are staggered. Such a design can ensure the overall stability of the weight, and is also convenient for the disassembly of the counter weight 4. Since each weight is divided into two semicircles, the weight of the transport unit is also reduced. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0013] Specific implementation mode three: combination figure 1 To illustrate this embodiment, in this embodiment, the semicircular joints of each adjacent two layers of counterweights 4 are staggered by 90°, so that the design can ensure the overall stability of the counterweights and facilitate the disassembly of the counterweights 4 , since each weight is divided into two semicircles, the weight of the transport unit is also reduced. The other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com