Blast furnace sintering linked low-cost molten iron preparation method

A production method and low-cost technology, applied in the field of ironmaking production, can solve the problems of low cost and inability to balance the positive and negative effects of using cost-effective iron ore powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

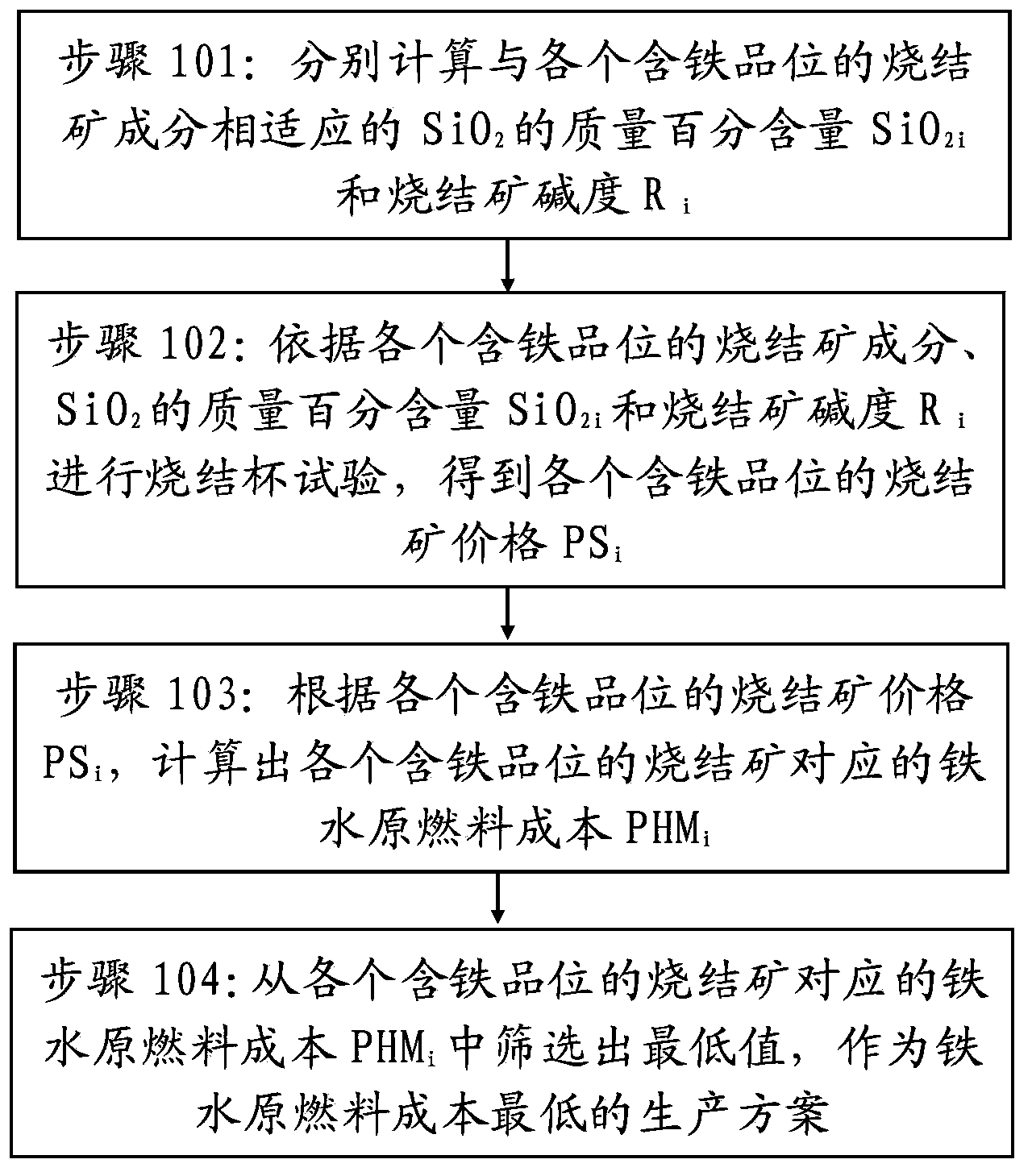

[0045] see figure 1 , a low-cost molten iron production method linked to blast furnace sintering provided by an embodiment of the present invention, comprising the following steps:

[0046] Step 101: According to the different iron-containing grades of sinter, slag basicity, the proportion of furnace charge, and the chemical composition of raw materials other than sinter, respectively calculate the composition of sinter suitable for each iron-containing grade. SiO 2 The mass percentage of SiO 2i and sinter basicity R i ;

[0047] Step 102: According to the sinter composition, SiO 2 The mass percentage of SiO 2i and sinter basicity R i Carry out the sinter cup test to get the sinter price PS of each iron grade i ;

[0048] Step 103: According to the sinter price PS of each iron grade i , to calculate the cost of hot metal raw fuel PHM corresponding to the sinter of each iron grade i ;

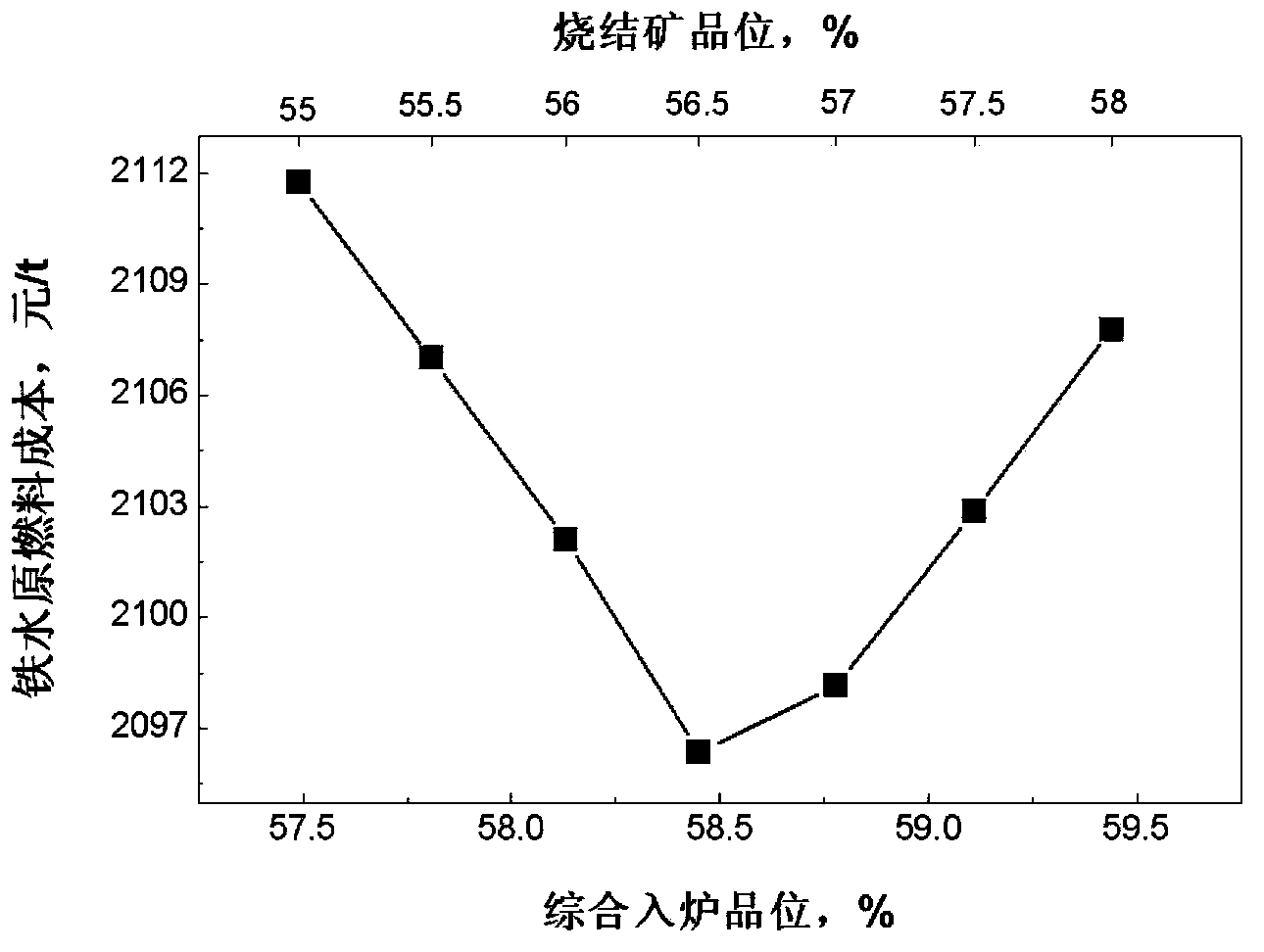

[0049] Step 104: From the raw material cost PHM of hot metal corresponding to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com