Carrier roller

A technology of idler and body, applied in the field of material transportation device accessories, can solve the problems of easily damaged mesh belt and increased cost, and achieve the effect of reducing friction and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

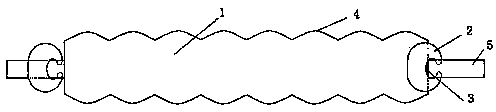

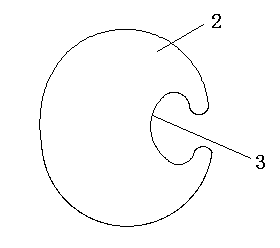

[0017] Such as figure 1 with figure 2 As shown, an idler roller of the present invention includes an idler body 1 and circular inserts 2 arranged on both sides of the idler body 1, and several protrusions 4 are provided on the idler body 1, preferably, the protrusions 4 Make it eight, the length of the protrusion 4 is 5-8cm, preferably 6cm, the size and shape of the protrusion 4 are consistent, the protrusion 4 is arranged side by side on the idler body 1 in sequence, and the setting of the protrusion 4 solves the problem caused by the large contact surface in the past. The problem of large friction force reduces the contact surface, reduces the friction force, reduces the damage to the mesh belt due to friction, and prolongs the service life of the mesh belt. , so it does not affect the operation balance of the mesh belt on the idler roller, the insert piece 2 is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com