Sensor circuit and calibration method

A sensor circuit and sensor technology, applied in the field of microphones, can solve the problems of no significant improvement in CMOS noise, options and cooling costs or high power, and increased input noise of CMOS readout circuits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

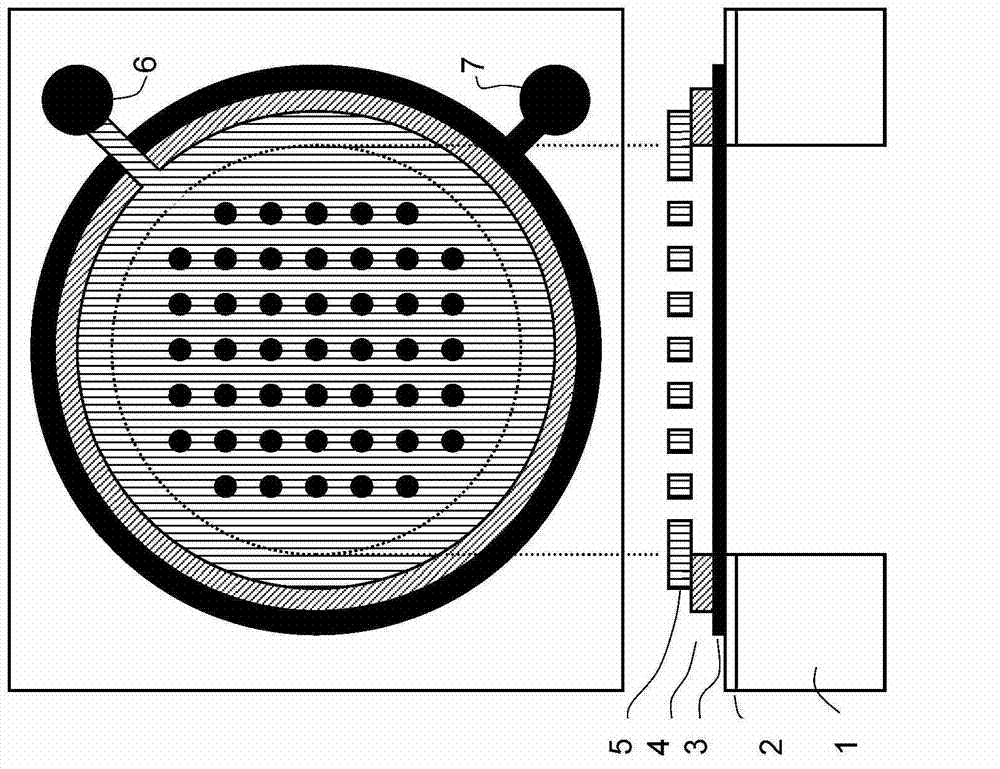

Image

Examples

Embodiment Construction

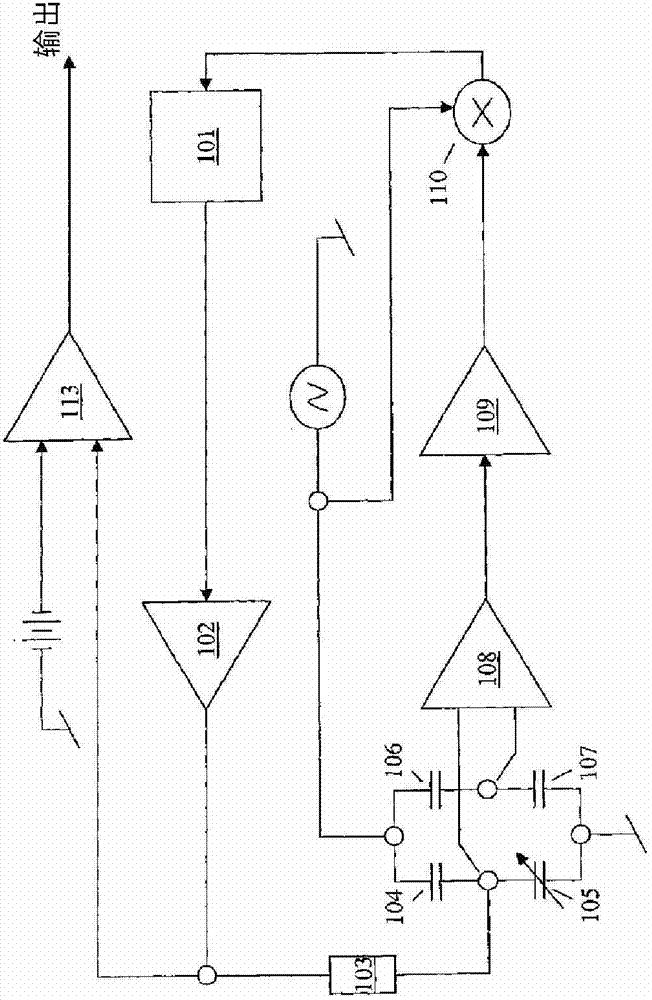

[0060] The present invention provides a sensor circuit using an AC signal source for generating a bias signal. A sensor having an impedance sensitive to the physical property to be measured is coupled between the signal source and the amplifier. A feedback loop structure around the amplifier controls the bias applied to the sensor element, wherein the feedback loop structure includes a first feedback control path for setting the bias level to a reference bias level, and a second feedback A control path for setting the reference bias level, wherein the first feedback control is faster than the second feedback control. Such a two-stage feedback system makes it possible to quickly set the bias point as a reference value in order to provide stable operation, and to adjust the reference point so that it can, for example, be closer to the limit of stability.

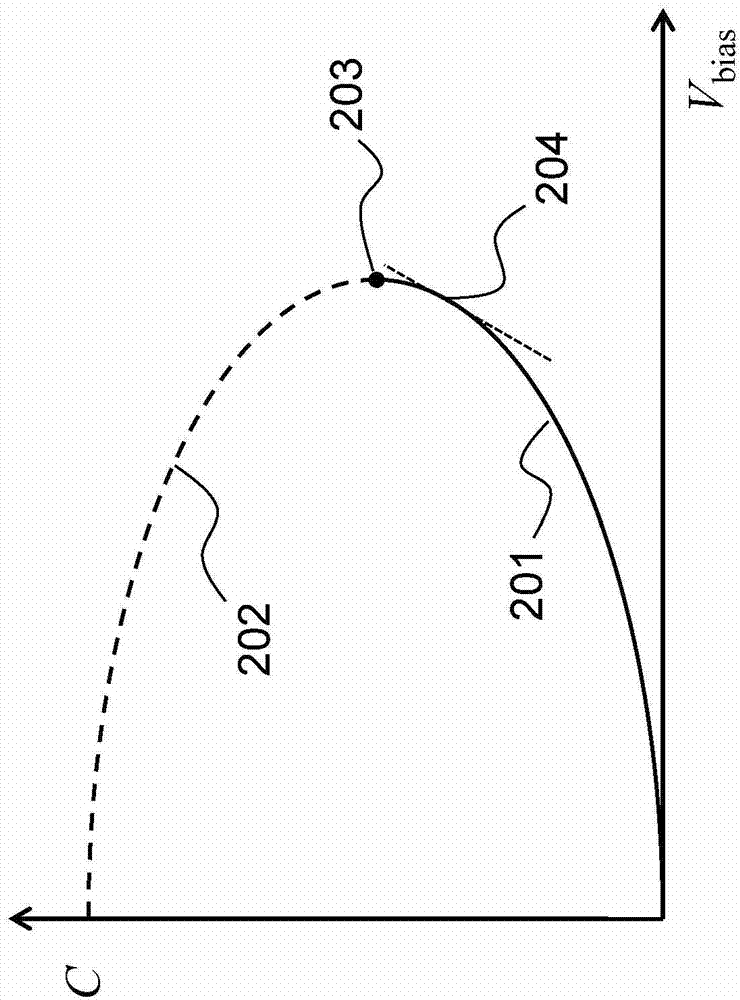

[0061] The noise level is reduced by increasing the electromechanical gain of the sensor. This is achieved by biasing clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com