A kind of photocatalyst and its preparation method for removing condensed water trace steam turbine oil

A photocatalyst and turbine oil technology, which is applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc., can solve the conditions of low load rate and photocatalytic degradation that are difficult to achieve , There is no such problem as an ideal material, and the effect of high load rate, low density and small grain size is achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

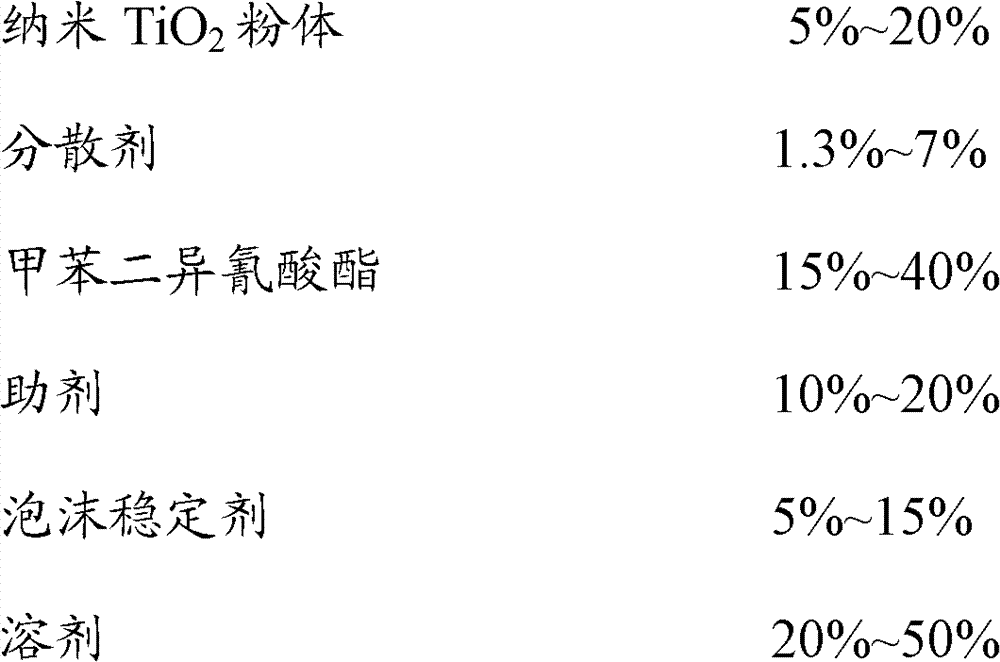

[0034] A photocatalyst for removing trace amounts of steam turbine oil, consisting of the following components:

[0035]

[0036]

[0037] The preparation method of the coating of Example 1 is:

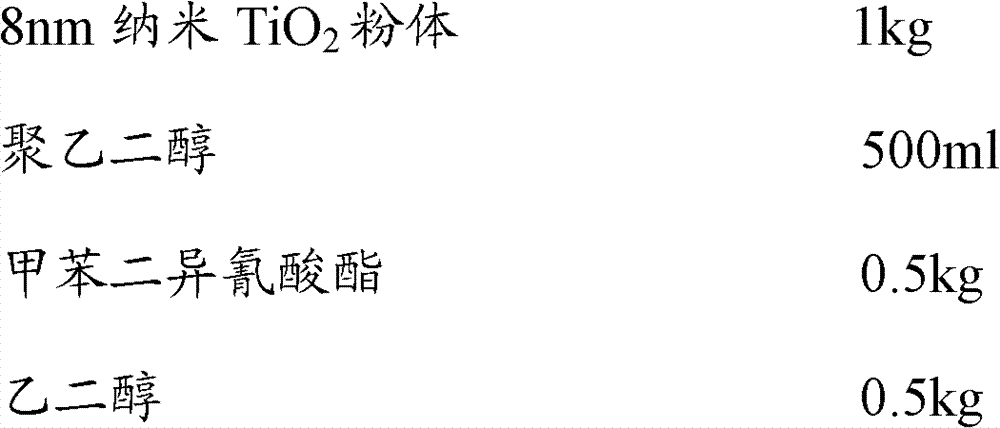

[0038] (1) Put 1kg of 8nm nano TiO 2 The powder was added to 4kg of deionized water and dispersed by ultrasonic for 0.5h to obtain nano-TiO with good dispersion 2 ;

[0039] (2) Add polyethylene glycol to the concentrated slurry, stir and disperse for 1 hour, and cool to room temperature;

[0040] (3) After cooling, add 0.5kg of toluene diisocyanate and stir at a certain temperature for 0.5h at a high speed to obtain a prepolymer;

[0041] (4) Add ethylene glycol, glycerol and polysiloxane to the prepolymer, and continue to stir for 0.25 hours;

[0042] (5) The mixture prepared in (4) is heated and kept for 12 hours for curing to obtain.

[0043] The photocatalyst of Example 1 was analyzed by SEM image of TiO 2 The particles are filled in the pores of the foam to ensure nano-TiO 2 The photocataly...

Embodiment 2

[0045] A photocatalyst for removing trace amounts of steam turbine oil, consisting of the following components:

[0046]

[0047]

[0048] The preparation method of the coating of Example 2 is:

[0049] (1) Put 15kg of 8nm nano TiO 2 The powder was added to 60kg of deionized water, and ultrasonically dispersed for 0.8h to obtain nano-TiO with good dispersion 2 ;

[0050] (2) Add polyethylene glycol to the concentrated slurry, stir and disperse for 1 hour, and cool to room temperature;

[0051] (3) After cooling, add 30kg of toluene diisocyanate, stir at a high speed for 0.8h at a certain temperature to obtain a prepolymer;

[0052] (4) Add ethylene glycol, glycerol and polysiloxane to the prepolymer, and continue to stir for 0.5h;

[0053] (5) The mixture prepared in (4) is heated and kept for 12 hours for curing to obtain.

[0054] The catalytic efficiency of the photocatalyst of Example 2 is above 90%, the number of repetitions is more than three times, and the catalytic efficiency is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com