Bake frying machine

A frying machine and baking pan technology, applied in frying pans, household appliances, applications, etc., can solve the problems of discontinuous screw adjustment, power consumption, unsightly electric baking pans, etc., to reduce the loss of heat and food moisture, Easy to package and store, simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

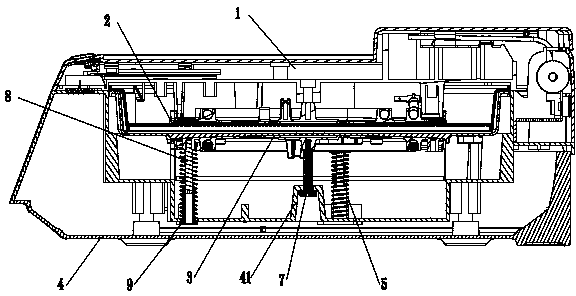

[0029] Such as figure 1 with figure 2 As shown, a grilling machine includes an upper shell assembly 1, an upper grill assembly 2, a lower grill assembly 3, and a lower shell assembly 4. The upper grill assembly 2 is placed in the upper shell assembly 1, and the lower grill assembly The disk assembly 3 is placed in the lower housing assembly 4, and the upper housing assembly 1 and the lower housing assembly 4 are hinged at one end and buckled at the other end to form a cavity with a fixed height.

[0030] Such as Figure 4 with Figure 5 As shown, the bottom of the lower baking pan assembly 3 is fixed with a guide post 8, and the bottom of the lower housing assembly 4 is fixed with a guide sleeve 9. The guide post 8 can slide freely and smoothly in the guide sleeve 9, and is a clearance fit. The outer side of the guide sleeve 9 is covered with a spring 5 , the lower end of the spring 5 is supported on the lower shell assembly 4 , and the upper end of the spring 5 is support...

Embodiment 2

[0036] A grilling machine, comprising an upper shell assembly (not shown in the figure), a lower shell assembly 4 , an upper grill assembly (not shown in the figure), and a lower grill assembly 3 . Wherein the upper grill assembly is placed in the upper shell assembly, and the lower grill assembly 3 is placed in the lower shell assembly 4 . Such as Image 6 , Figure 7As shown, the lifting device in this embodiment is a screw pair and a gear 12; the screw pair includes a screw 11 and a screw nut 16, wherein the screw 11 is fixed on the bottom of the lower baking pan assembly 3, and the lower baking pan assembly 3 Floating up and down, the screw nut 16 is fixed in the lower housing assembly 4, and the gear 12 is installed in the lower housing assembly 4 so as to be horizontally rotatable. The gear 12 includes a driving disc 122 and an adjusting disc 121, and the gear driving disc 122 meshes with the screw nut 16 , a portion of the adjusting disc 121 is exposed from the lower ...

Embodiment 3

[0039] The basic structure of this embodiment is the same as that of Embodiment 2, the difference is that Figure 8 As shown, the lifting device in this embodiment is a rack 13 and a gear 14 arranged between the lower shell assembly 4 and the lower grill assembly 3; the rack 13 is vertically arranged, and its top end is fixed on the bottom of the lower grill assembly 3 The gear 14 is axially rotatably installed in the lower housing assembly 4, and the gear 14 meshes with the rack 13. The rotation of the gear 14 can drive the rack 13 to move up and down, thereby realizing the floating of the lower grill assembly 3 up and down. The center of the gear protrudes from the adjustment rod, and the adjustment rod is exposed from the side of the lower housing assembly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com