Electric motor and method for mounting the electric motor

A technology of installation direction and armature, which is applied in the direction of engine starting, machine/engine, engine motor starting, etc., which can solve problems such as expensive starter installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

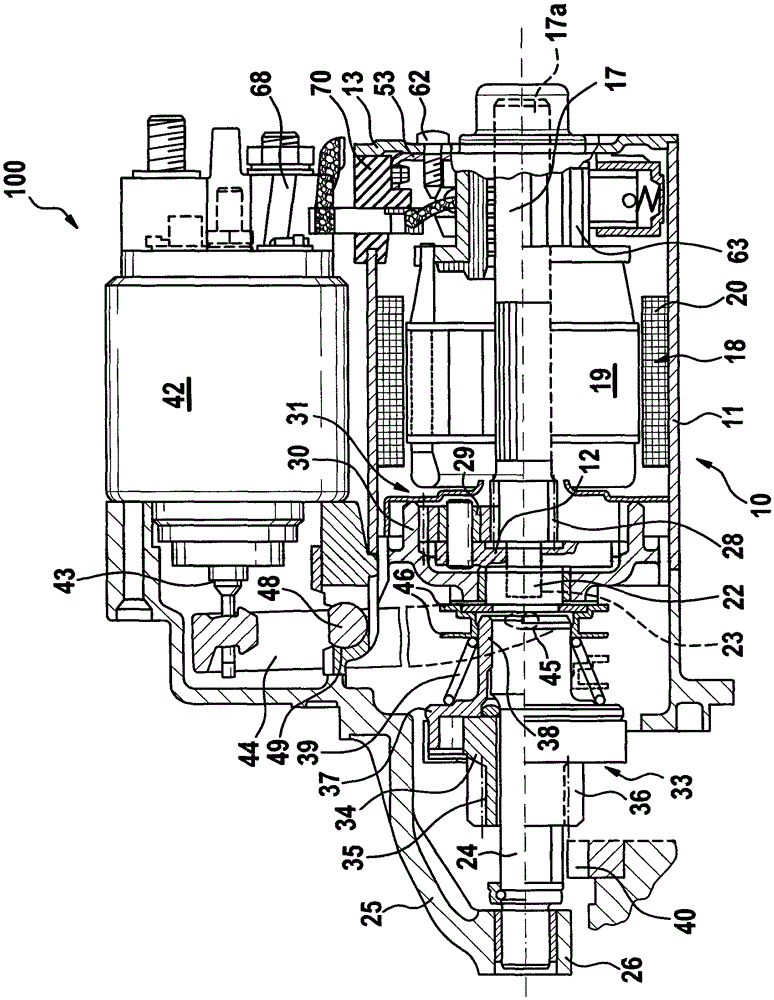

[0028] figure 1 Shown is a cross-sectional view of an electric machine 100 of an internal combustion engine designed as a starter with a relay 42 , which can also be embodied as a distribution relay or as a switch-on relay. The starter housing 10 comprises a cylindrical housing part 11 and a cover 13 , which are connected to each other by screws, not further shown. The cylindrical housing part 11 is closed at the rear by a cover 13, the middle part of which forms an outwardly pointing hub (not shown in detail here). In the hub there is a journal which bears the rear end 17a of the armature shaft 17 of the starter motor 18 , the armature of which is indicated by 19 . Radially on the outside of the armature 19 there are a plurality of (permanent) magnets 20 of the starter motor 18 on the wall of the housing part 11 . The front end of the armature shaft 17 is supported with a reduced-diameter end section 22 in a blind hole 23 of a coaxially extending output shaft 24 , not shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com