Vertically-inserting-type ceramic tile locating horizontal mounting device

A technology for installing devices and ceramic tiles, which is applied in the direction of architecture and building construction, etc., can solve the problems of easily damaged tiles, low work efficiency, and waste, and achieve the effects of reducing use costs, improving work efficiency, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

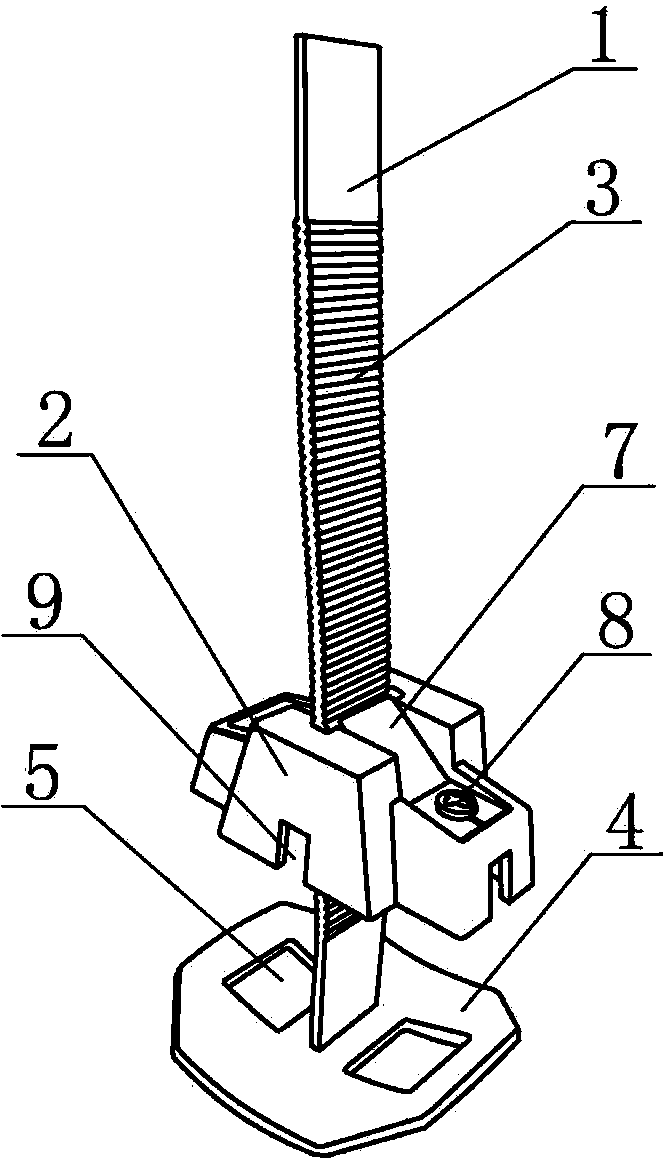

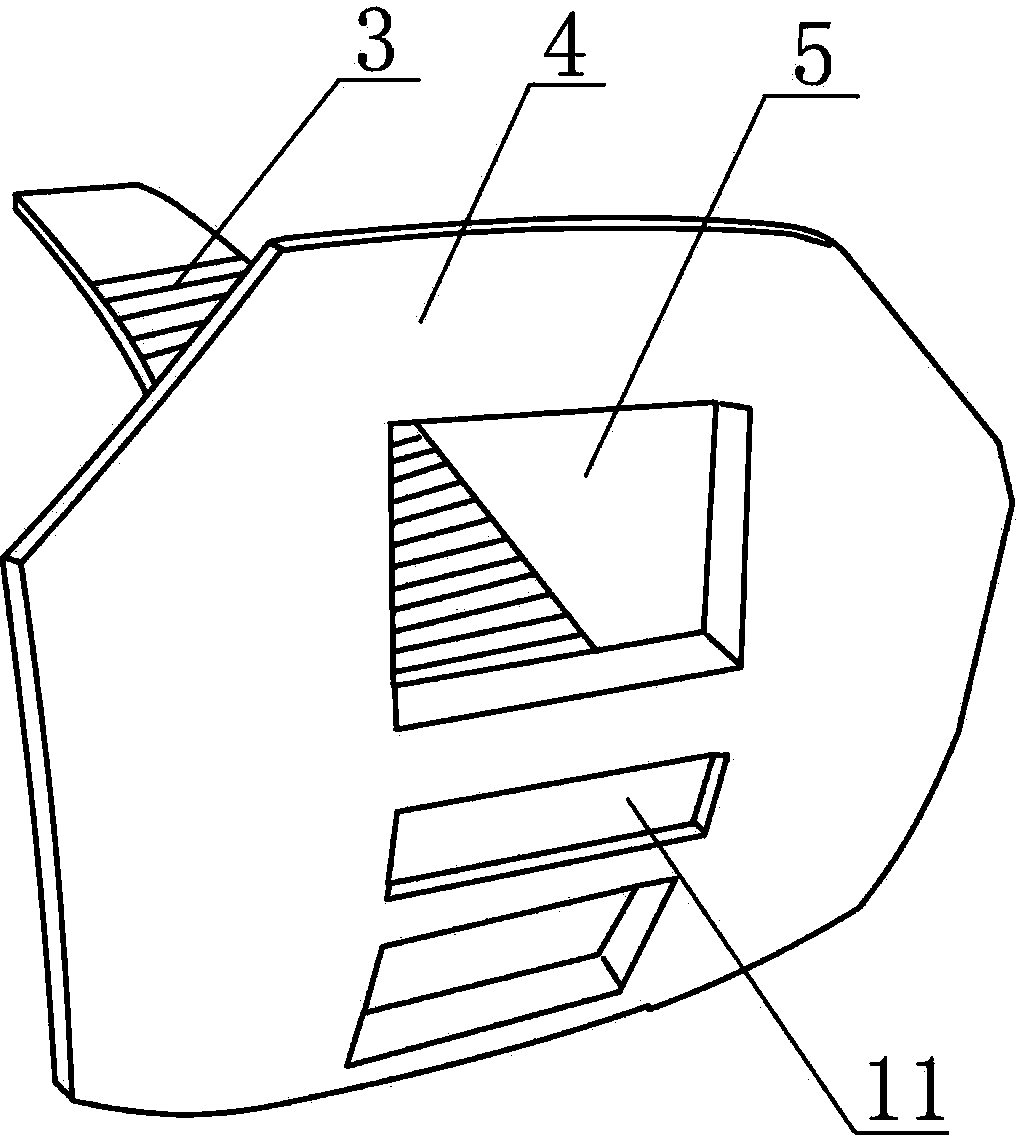

Embodiment 1

[0024] Embodiment 1: as Figure 5 As shown: spread the well-mixed cement on the wall or the ground where the ceramic tile 10 needs to be laid, set the positioning seat 1 according to the size of the ceramic tile 10, place two ceramic tiles 10 symmetrically on the bottom plate 4 on both sides of the rack 3, and then place the The rectangular hole 6 of the compression block 2 is put on the rack 3, and the compression block 2 is pressed firmly, and the two ceramic tiles 10 are pushed down simultaneously. Now one end of the pressing plate 7 bears against the rack 3, and the upward elastic force at the two ends of the curved bottom plate 4 keeps the surfaces of the two tiles 10 flat, and adjusts the gap between the two tiles 10 to keep them parallel. 10 After the paste is laid and dried, lightly kick the positioning seat 1 sideways with your foot or pull the positioning seat 1 with a special tensioning tool, the connection between the rack 3 and the bottom plate 4 will break, and r...

Embodiment 2

[0025] Embodiment 2: as Figure 6 Shown: spread the well-mixed cement on the wall or the ground where the tiles 10 need to be laid, set the positioning seat 1 according to the size of the tiles 10, and place four tiles 10 symmetrically on the rack 3 based on the center line of the rack. On the bottom plates 4 on both sides, then put the rectangular hole 6 of the pressing block 2 on the rack 3, press the pressing block 2 firmly, and press the four corners of the four ceramic tiles 10 at the same time, at this time, one end of the pressing plate 7 is on the top Hold the rack 3, add the upward elastic force at both ends of the arc-shaped bottom plate 4, keep the surfaces of the four tiles 10 flat, and adjust the gap between the tiles 10 and the tiles 10 with reference to the square gap 9 on the pressing block 2, keep it parallel. The recovery method of the compacted block 2 is the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com