Special ground conducting wire hydraulic compression connector for transmission line

A technology of power transmission lines and ground wires, which is applied in the direction of connection and connection by deformation, connection/termination of cables, etc., which can solve the problem that it is difficult to ensure the long-term safe use of crimping points, no public patent documents have been found, and the quality of righting cannot be guaranteed, etc. Problems, to achieve reliable crimping, low cost and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings. It should be noted that this embodiment is descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

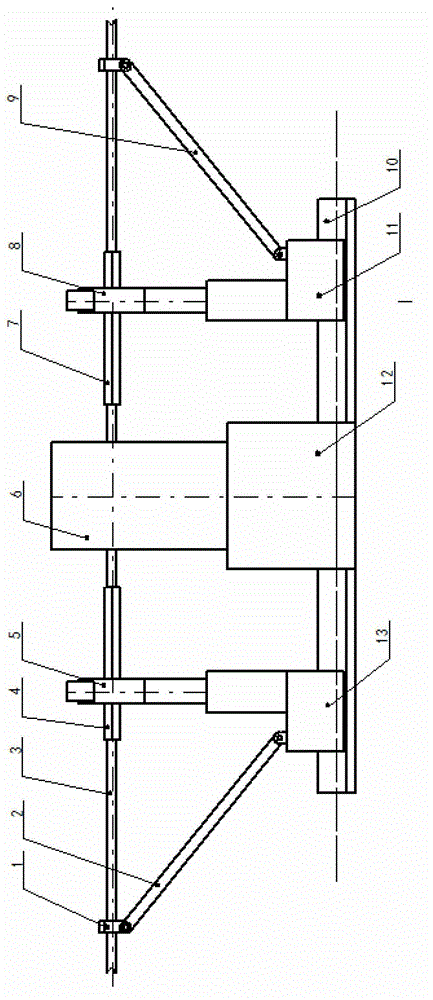

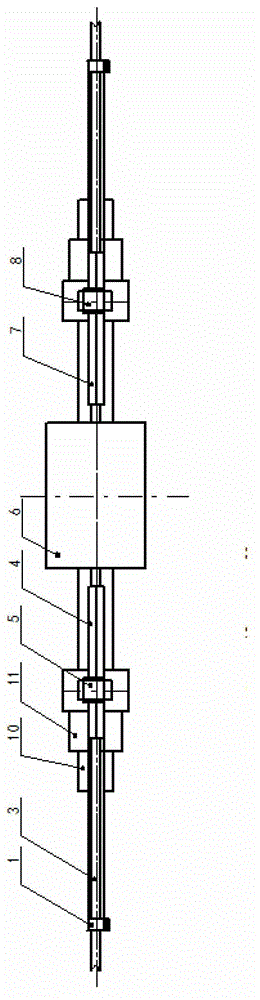

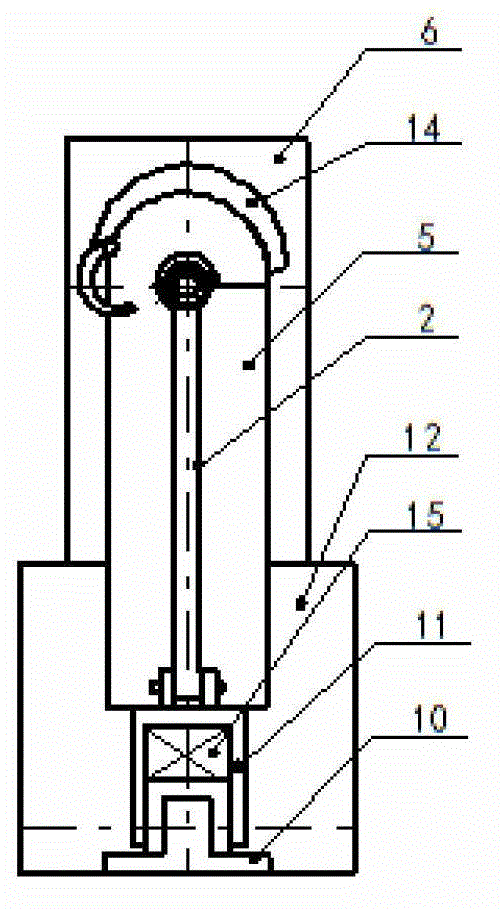

[0019] A hydraulic crimping device for ground wires dedicated to power transmission lines, including hydraulic clamps 6, left clamps 5, right clamps 8, left lifting rods 2, right lifting rods 9 and channel steel guide rails 10, the hydraulic clamps pass through the positioning seat 12 Positioning is installed in the middle of the channel steel guide rail, and the left and right clamps are symmetrically arranged on the left and right sides of the hydraulic pliers. Sliding operation, the mounting holes made by the left jig, hydraulic pliers and right jig are on the same axis. Bearing 15 is all installed between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com