Dual-cured scratch-resistant wear-resistant water-based black luster finish coat

A dual-curing, water-based black paste technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problem of difficult-to-curing non-planar components, fullness, scratch resistance, hardness and anti-blocking resistance, and limited use. and other problems, to achieve the effect of fast drying and curing paint film mechanical properties, excellent paint film mechanical properties, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

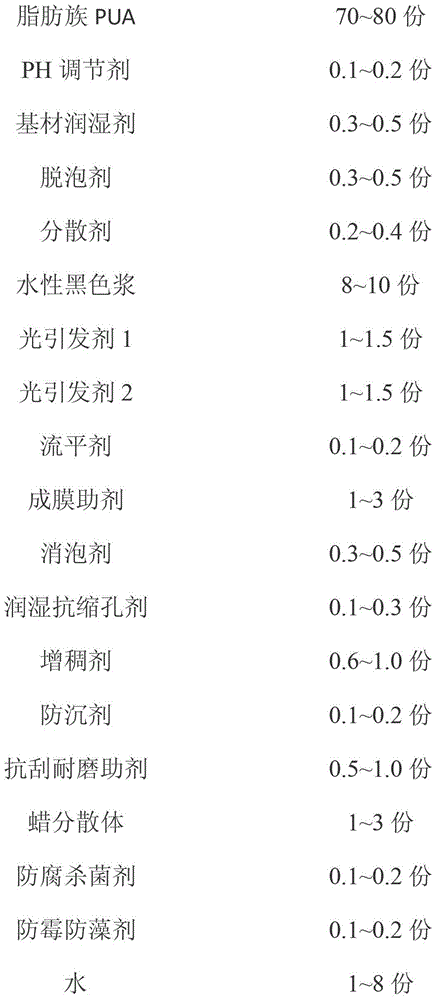

Method used

Image

Examples

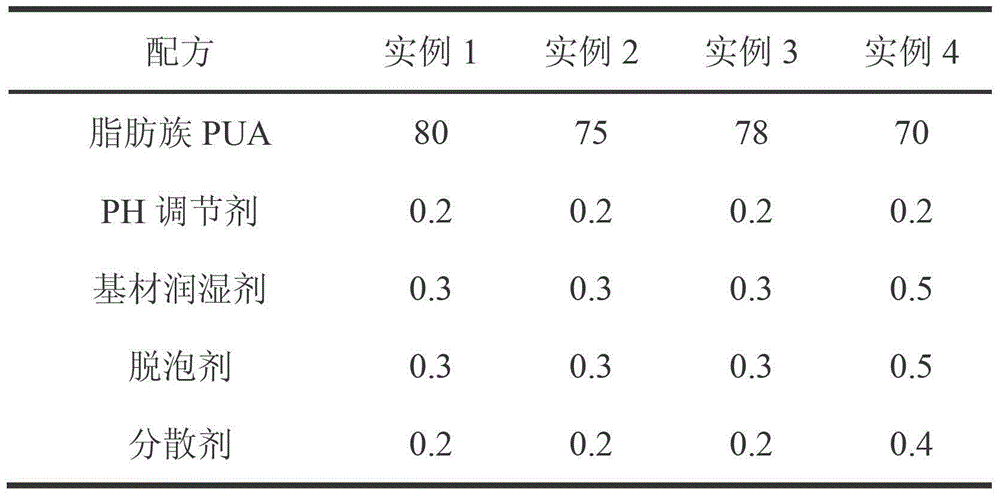

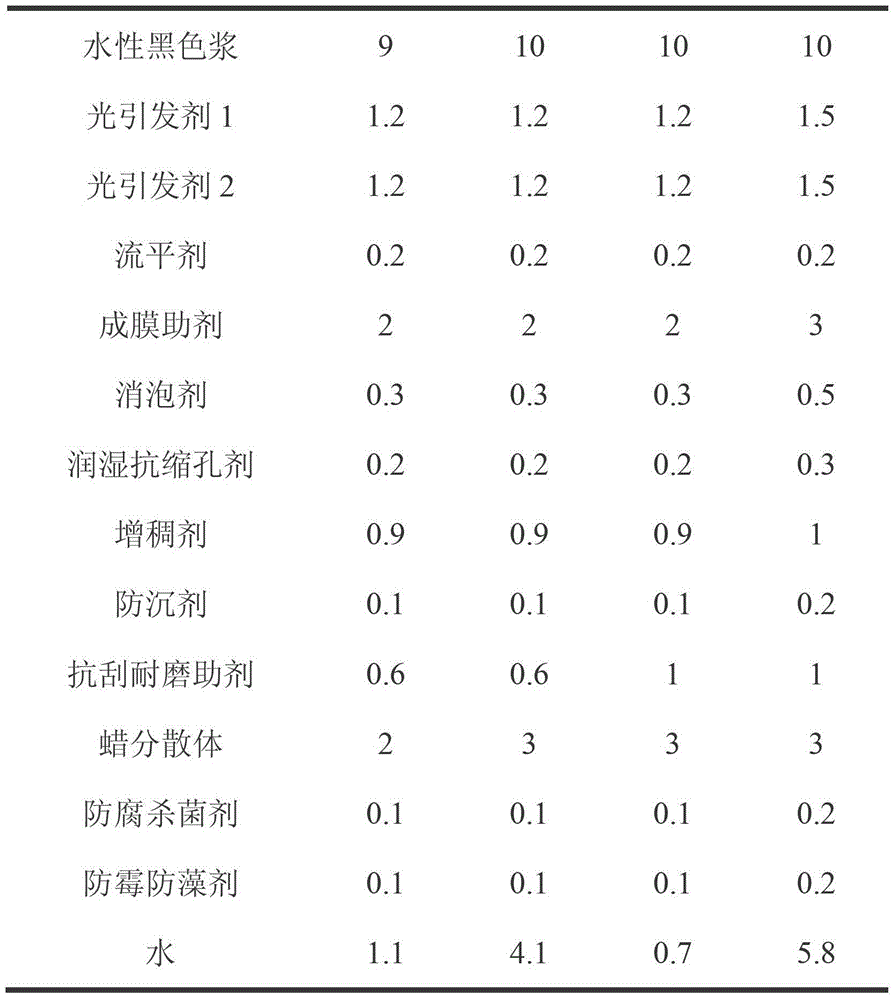

Embodiment 1-4

[0038] Embodiment 1-4 concrete preparation method is:

[0039] (1) Add aliphatic PUA to the dispersing tank, then add PH regulator, stir and disperse for 5 minutes;

[0040] (2) Add substrate wetting agent, defoamer, dispersant and water-based black paste in sequence, stir and disperse for 10 minutes;

[0041] (3) Choose another container to add 1 part of film-forming aid, photoinitiator 1 and photoinitiator 2 and stir evenly, slowly add to the dispersion tank, and stir for 10 minutes;

[0042] (4) Slowly add part of the premix of water and the rest of the film-forming aid, and stir for 15 minutes;

[0043] (5) Add leveling agent, defoamer, wetting and anti-cratering additive, thickener, anti-sedimentation agent, anti-scratch and wear-resistant additive, and wax dispersion in the dispersion tank in turn, and stir for 20 minutes;

[0044] (6) Finally, mix the remaining amount of water with antiseptic and fungicide, anti-mildew and anti-algae agent, and slowly add it to the di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com