Permanent magnet coupling mechanism between shafts

A permanent magnetic coupling and inter-shaft technology, applied in the direction of electromechanical devices, electromechanical transmission devices, electrical components, etc., can solve problems such as difficult to accurately ensure two-axis alignment, scattered magnetic field distribution, complex structure and operation, etc., to reduce adjustment Displacement, concentricity requirements are reduced, and the effect of wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

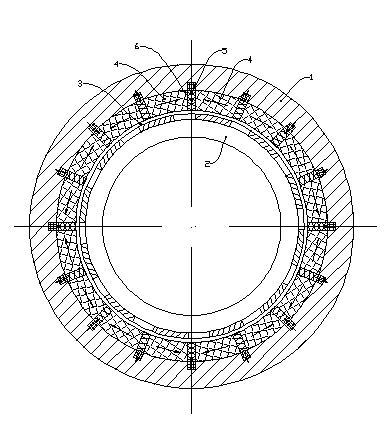

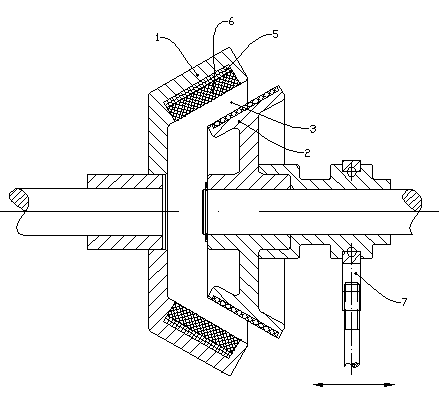

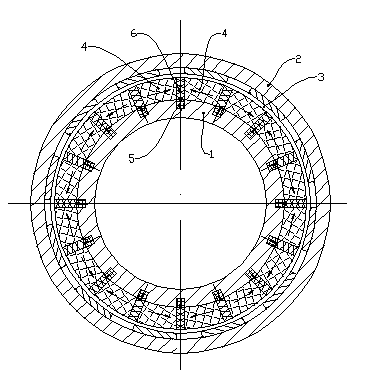

[0016] As shown in the figure, the inter-shaft permanent magnetic coupling mechanism of the present invention includes a coaxially arranged permanent magnet rotor 1 and a conductor rotor 2. Permanent magnets and conductors are respectively distributed on the permanent magnet rotor 1 and the conductor rotor 2. The permanent magnet rotor 1 There is a conical air gap 3 between the conductor rotor 2; the permanent magnet on the permanent magnet rotor 1 includes a main magnet 4 and an auxiliary magnet 5; a plurality of main magnets 4 are distributed along the circumference, and are arranged between adjacent main magnets 4 There are magnetizers 6 made of magnetically permeable materials; the auxiliary magnets 5 are located on the side of each magnetizer 6 away from the conductor rotor 2; Direction) is located in the circumferential direction of the permanent magnet rotor, and the magnetic pole direction of the adjacent main magnet 4 (indicated by the arrow direction in the figure) is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com