Rotation type three-proofing insulator

An insulator and rotary technology, applied in the field of rotary three-proof insulators, can solve the problems of enhanced insulator flashover grounding, large manpower consumption, material and financial resources, economic losses, etc., and achieves stable and reliable operation, reduced manpower, and scientific design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

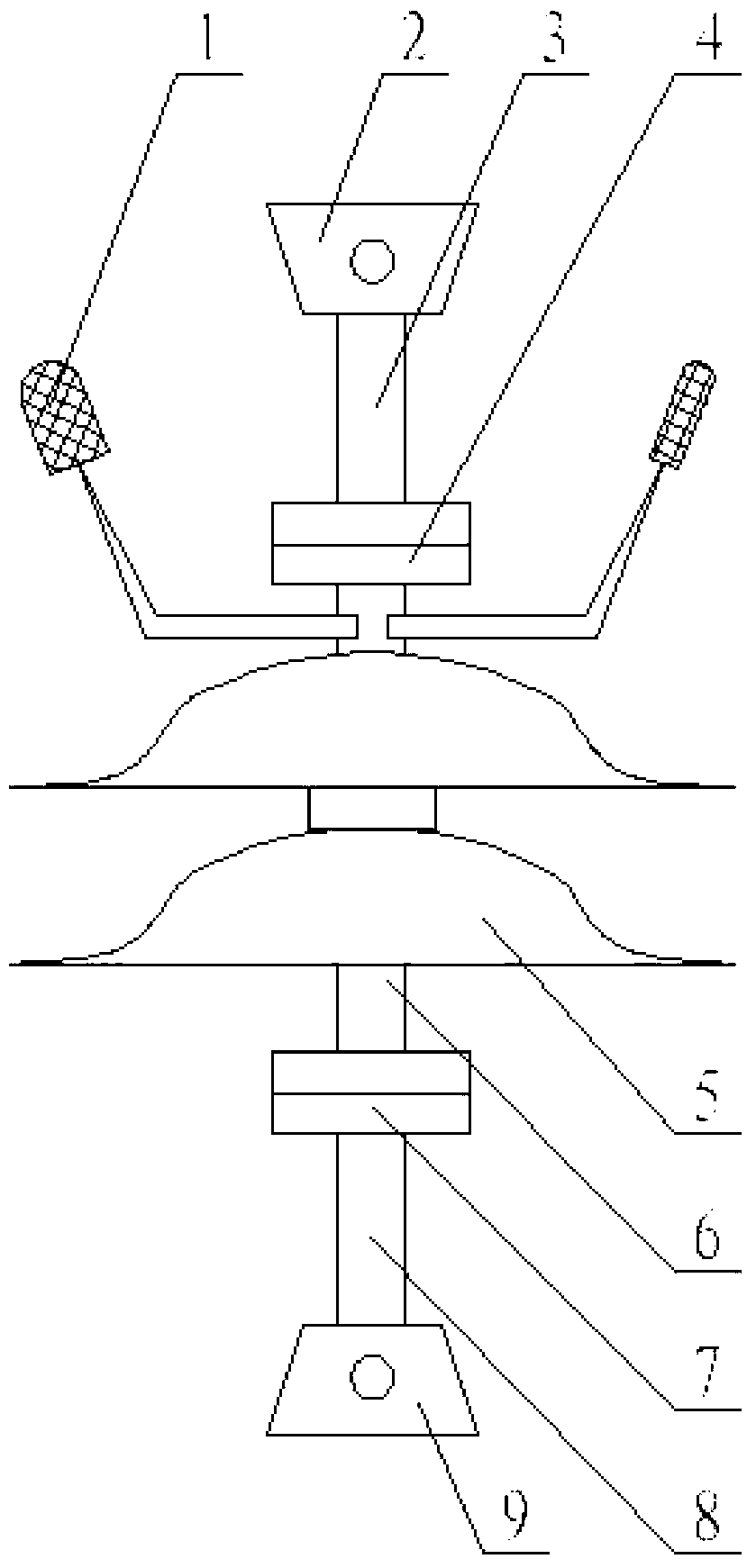

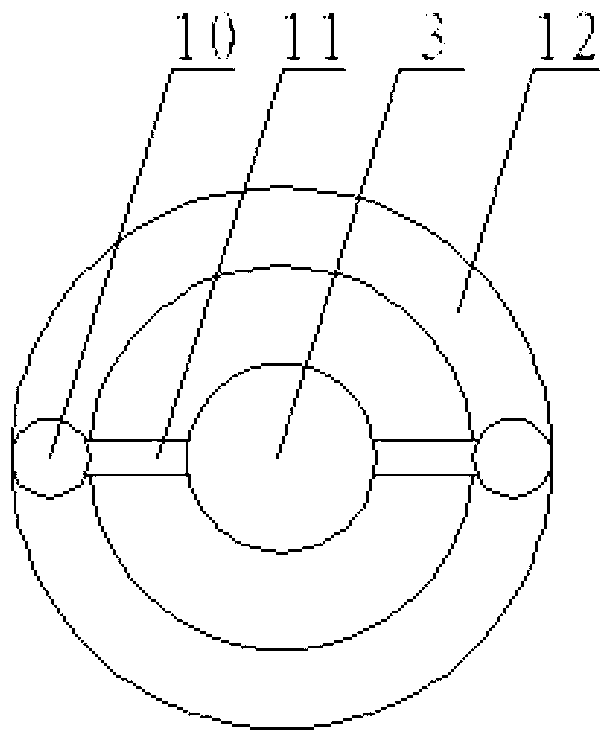

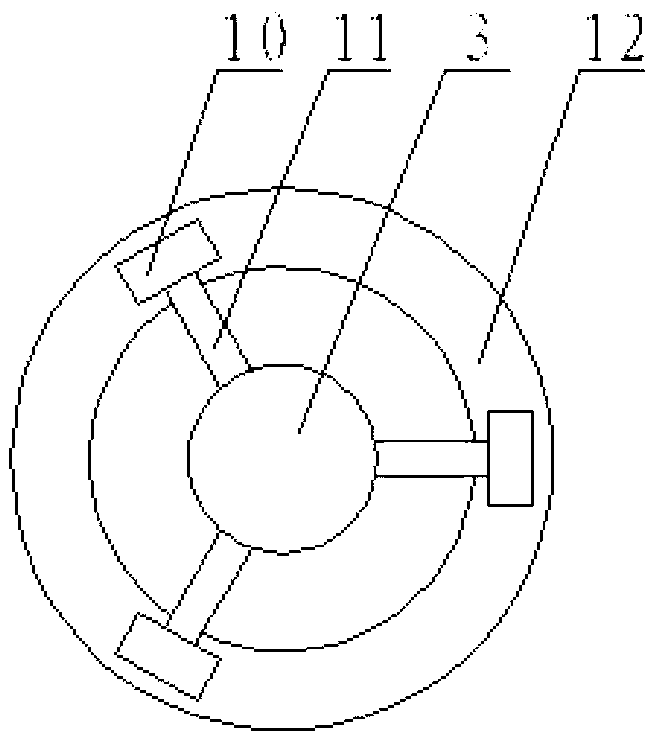

[0022] A rotary three-proof insulator includes a fixed handle 2, a suspension shaft, an insulator shed 5 and a suspension handle 9. The innovation of the present invention is: the fixed handle is installed on the upper end of the upper suspension shaft 3, and the lower end of the upper suspension shaft is rotatably installed in an upper rotation shaft 4, and the specific installation method is: an annular slide rail is arranged in the upper rotation shaft Slot 12, the lower end of the upper suspension shaft is evenly distributed along the circumferential direction with a set of slide rail bead shafts 11, each slide rail bead shaft is connected with a slide rail bead 10, and all slide rail beads are slidably insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com