Unidirectional-stitch sewing machine

A sewing machine and stitching technology, which is applied in the field of sewing machines, can solve the problems of inconvenient threading and unsightly appearance of stitches, and achieve the effects of convenient threading, beautiful appearance and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described below in conjunction with accompanying drawing.

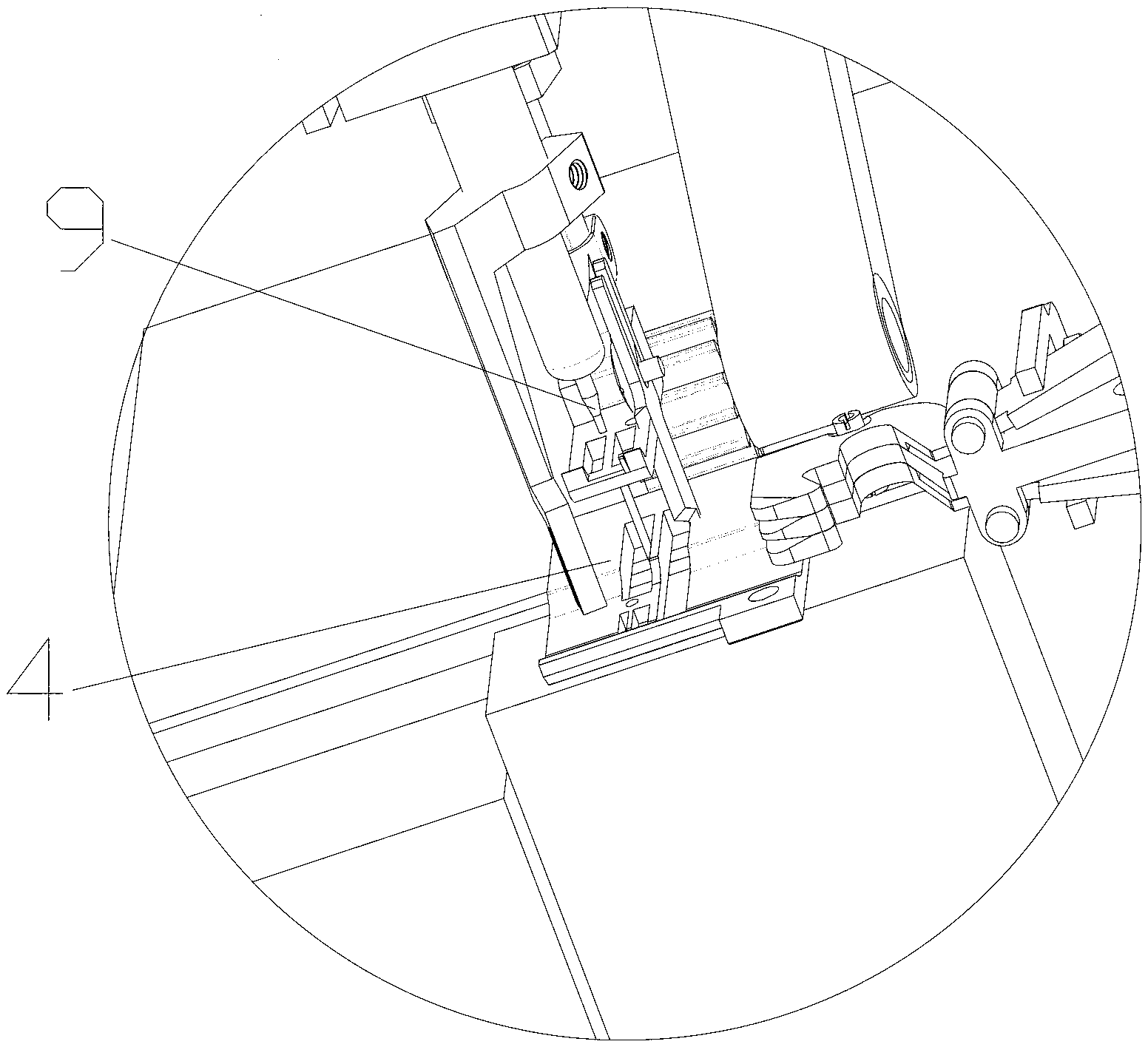

[0017] as attached figure 1 , 2 Shown is a one-way stitch sewing machine according to the present invention, including a frame 1, a sewing machine head 2 including a plurality of parts including sewing needles 3 and a needle plate 4, and a transmission mechanism for controlling the sewing of the head (not shown in the figure), the needle plate 4 is provided with an installation hole 5 and a cloth running groove 6, and the needle plate 4 is also provided with a concave platform 7, and the concave platform 7 is provided with a ring-shaped sewing Pinhole 8; the upper side of the needle plate 4 is connected with a baffle plate 9; the baffle plate 9 is located beside the sewing needle hole 8; the baffle plate 9 is arc-shaped; the gap between the baffle plate 9 and the needle plate 4 The space is a threaded connection fixedly connected by screws; the screws are hexagon socket head cap screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com