Trolley line support and manufacturing method thereof

A manufacturing method and a trolley wire technology, which are applied in the field of supports, can solve the problems of material consumption, poor stability, and large structural deformation of the trolley wire support, and achieve the effects of saving materials and labor costs, and improving stability and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

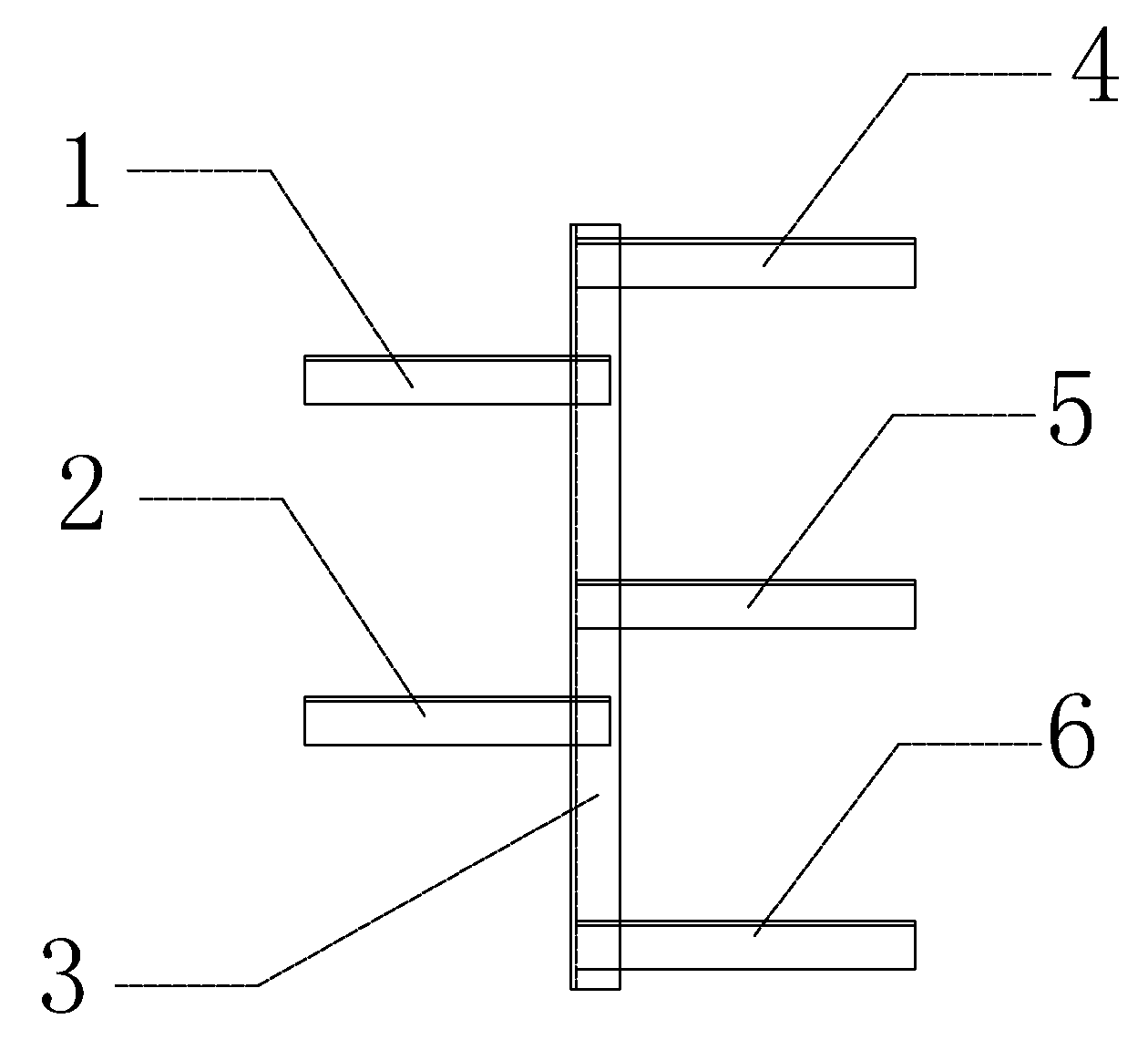

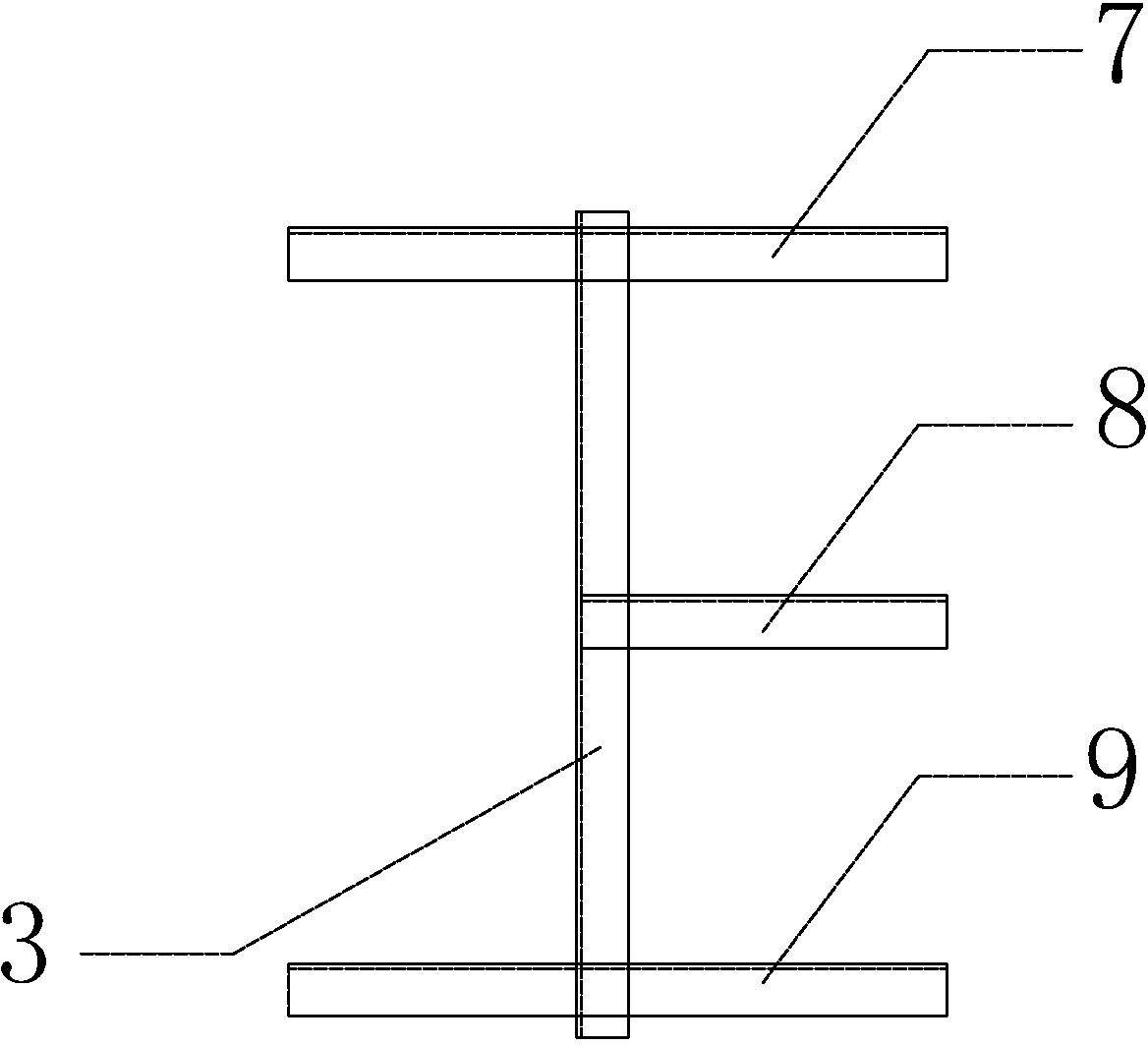

[0035] A trolley wire support for a crane power supply line, comprising an angle steel column 3, an upper angle steel beam 7, a middle angle steel beam 8 and a lower angle steel beam 9, characterized in that:

[0036] Described angle steel column 3 is the angle steel of side length 10cm, and length is 785mm;

[0037] The middle angle steel beam 8 is an angle steel with a side length of 10 cm and a length of 355 mm, one end of which is solidly welded to the middle part of the angle steel column 3, and the other end is provided with a connecting hole;

[0038] Described upper angle steel beam 7 and lower angle steel beam 9 are two side length 10cm angle steels, and length is 630mm, and the middle part of described two angle steels is fixedly welded on the upper and lower two ends of described angle steel column 3 respectively, makes all The distance from the middle angle steel beam 8 to the upper angle steel beam 7 and the lower angle steel beam 9 is equal, which is 350mm, and t...

Embodiment 2

[0040] A method for manufacturing a trolley wire support, characterized in that it comprises the following steps:

[0041] a. Select and cut angle steel

[0042] Select an angle steel with a side length of 10cm, and cut four angle steels of the required length: the angle steel column 3 is 785mm, the middle angle steel beam 8 is 355mm, the upper angle steel beam 7 and the lower angle steel beam 9 are each 630mm;

[0043] b. Assemble and weld the bracket

[0044] One end of the middle angle steel beam 8 is assembled and welded on the middle part of the angle steel column 3, and the other end is provided with a connecting hole; , the lower two ends; also include the ends of the upper angle steel beam 7 and the lower angle steel beam 9 to be arranged on the same side as the middle angle steel beam 8 to be provided with connecting holes.

[0045] c. Calibration bracket

[0046] Correct the bracket so that the distance from the middle angle steel beam 8 to the upper angle steel b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com