Centrifugal fan

A technology of centrifugal fans and blades, which is applied to components of pumping devices for elastic fluids, non-variable pumps, machines/engines, etc. It can solve the problems that it is difficult to promote air circulation and improve air volume characteristics, and achieve Excellent air volume characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

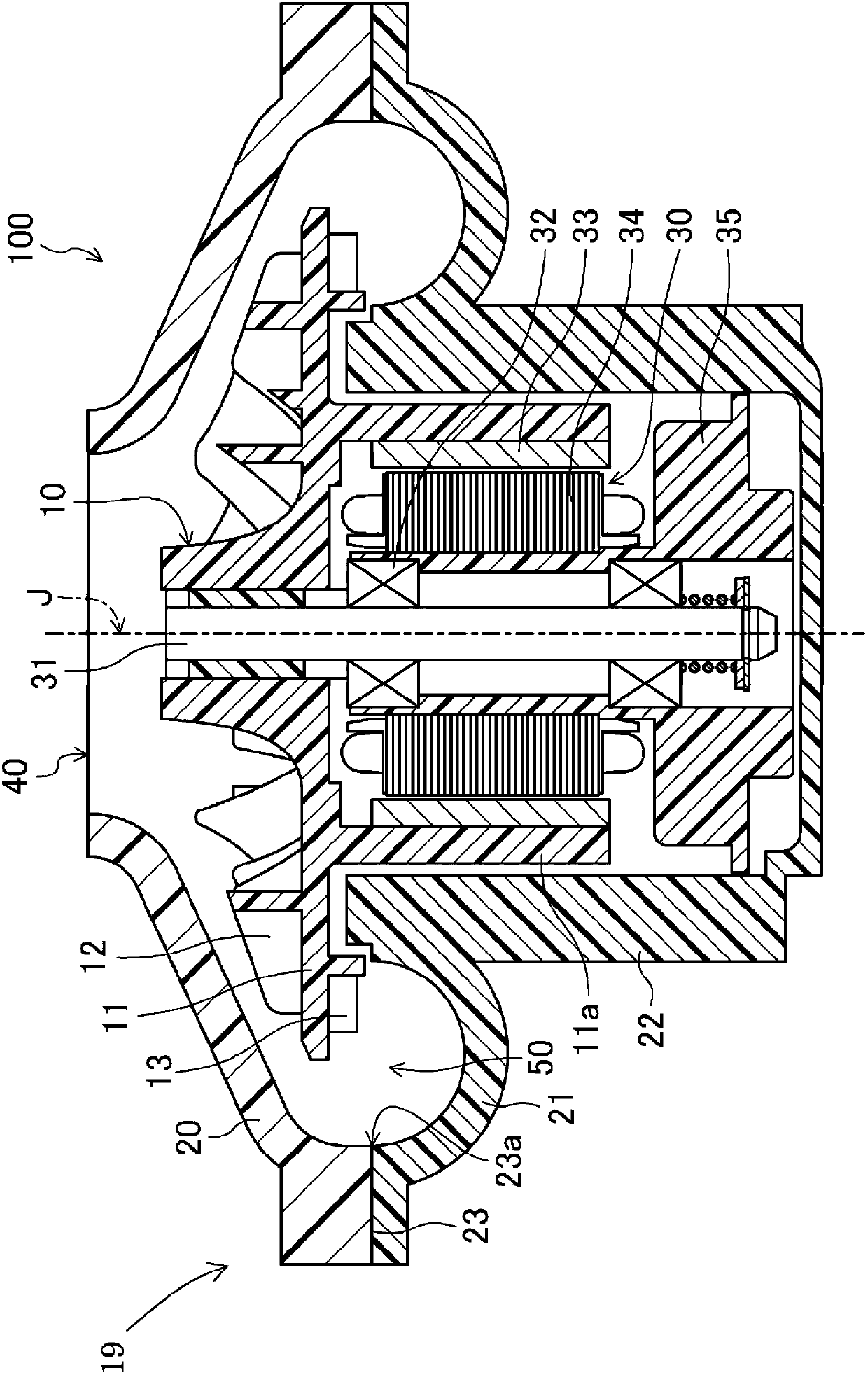

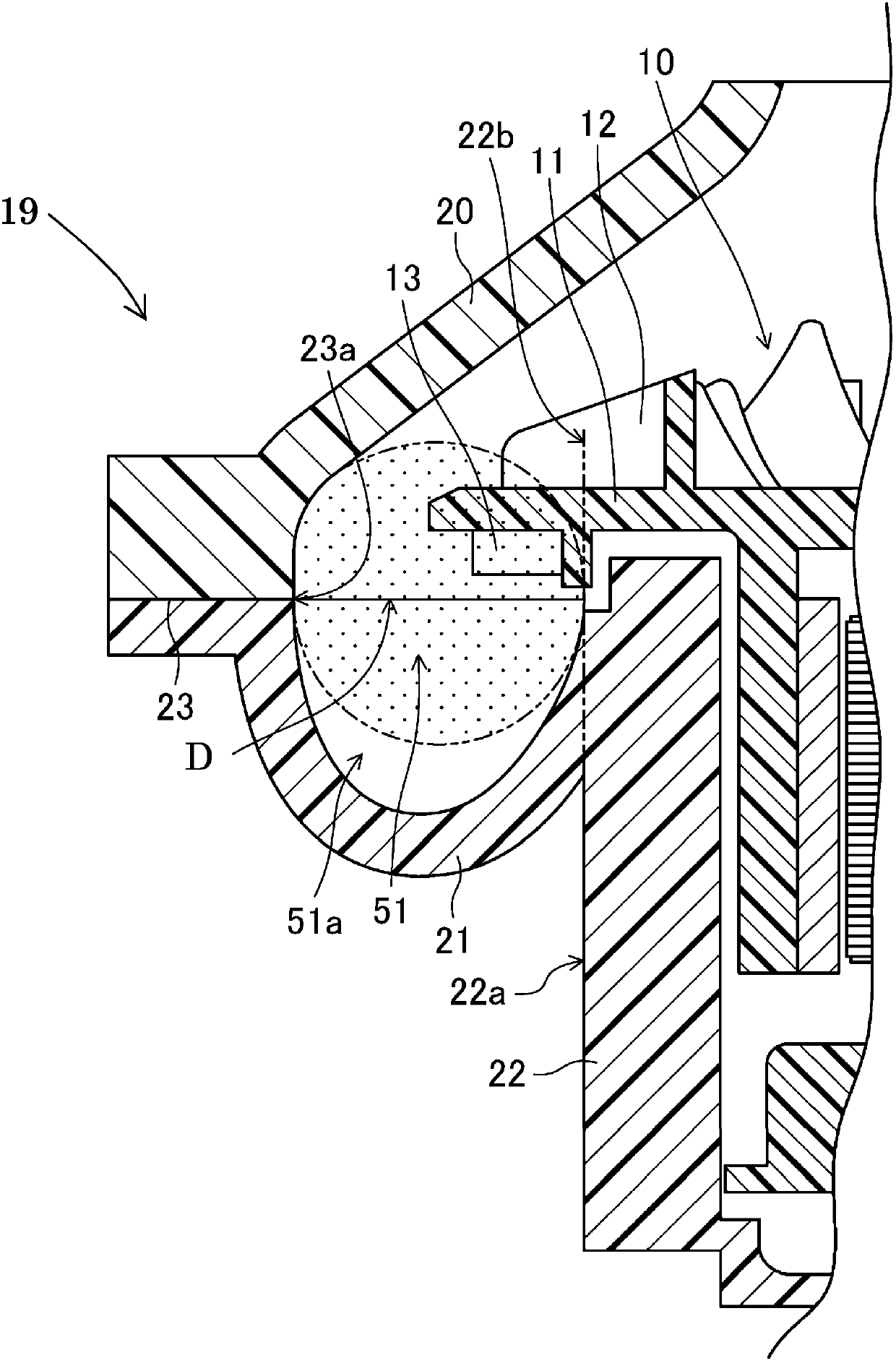

[0019] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. In addition, in the description of this embodiment, the direction parallel to the rotation axis is referred to as "axial direction", the direction perpendicular to the rotation axis is referred to as "radial direction", and the direction toward the circumference of the rotation axis is referred to as "radial direction". Called "peripheral". Then, the shape and positional relationship of each part will be described with the direction along the axial direction being the up-down direction and the impeller side being up with respect to the motor. In addition, the present invention is not limited to the following embodiments. Appropriate changes can be made without departing from the effects achieved by the present invention. And it can also be combined with other embodiments.

[0020] figure 1 It is a cross-sectional view which schematically shows the structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com