Compound chemical coal dust suppressant and preparation method thereof

A compound type, dust suppressant technology, applied in the field of environmental pollution control, can solve unseen problems, achieve the effects of flexible use, suppression of coal dust flying, and prevention of dust flying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

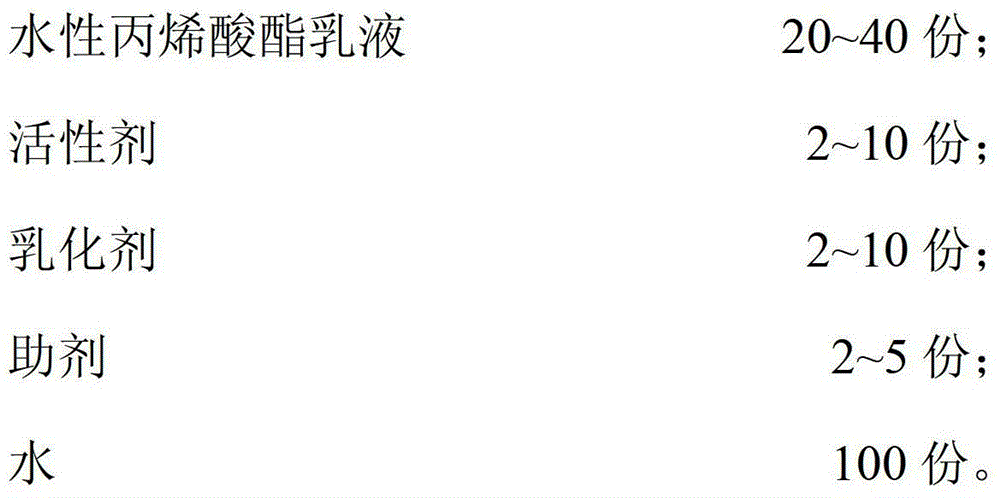

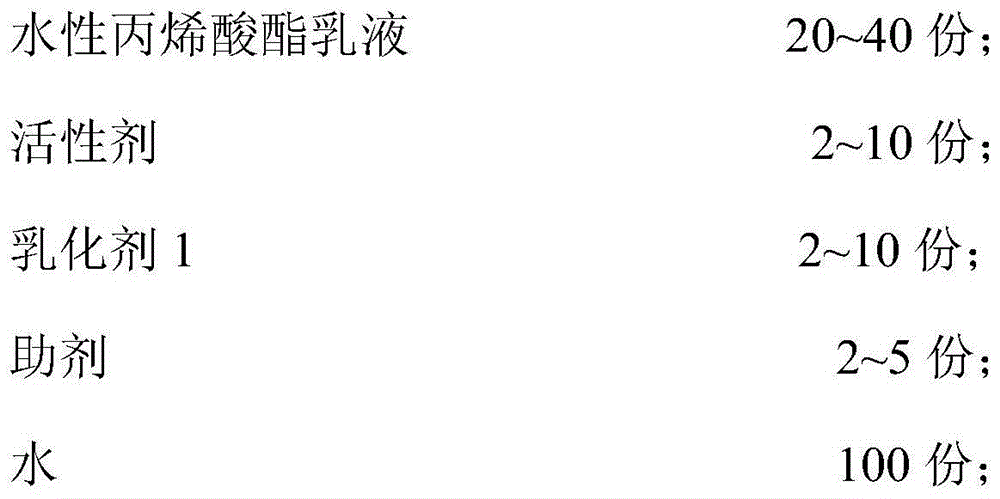

[0030] Prepare the preparation method of compound type coal dust chemical dust suppressant of the present invention, comprise the steps:

[0031] At first prepare aqueous acrylic ester emulsion, comprise the following steps:

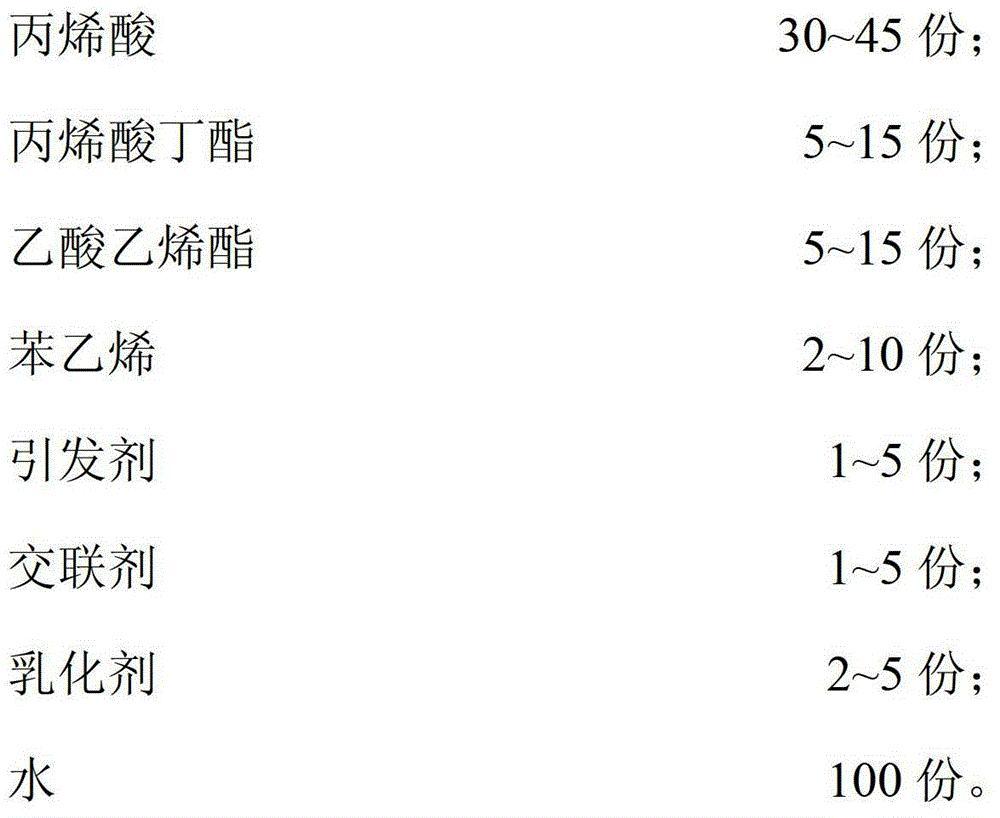

[0032] 30-45 parts by mass of acrylic acid, 5-15 parts of butyl acrylate, 5-15 parts of vinyl acetate, and 2-10 parts of styrene are mixed in proportion to form a mixed solution for later use. Add 100 parts by mass of water and 2 to 5 parts of emulsifier into a reaction kettle equipped with a stirrer, a thermometer, a reflux condenser and a feeding device, stir and heat in a water bath. When the temperature rises to 65-80°C, add 1-5 parts of the initiator, and at the same time, drop the above-mentioned mixed solution from the dropping funnel, control the dropping speed, and complete the dropping within 2-3 hours. Keep warm for 1 hour, then add 1 to 5 parts of cross-linking agent, stir for 1 hour, then cool down and discharge. The appearance of the prod...

Embodiment 1

[0039] 30 parts by mass of acrylic acid, 5 parts of butyl acrylate, 15 parts of vinyl acetate and 2 parts of styrene are mixed in proportion to form a mixed solution for later use. Add 100 parts of water, 2 parts of the mixture of emulsifier sodium dodecylbenzenesulfonate and OP-10 in a ratio of 1:1 to the reaction kettle equipped with a stirrer, a thermometer, a reflux condenser and a feeding device, stir and use Water bath. When the temperature rises to 65°C, add 1 part of the initiator ammonium persulfate and potassium persulfate, and at the same time, add the above mixed solution dropwise from the dropping funnel, control the dropping rate, and complete the dropwise addition within 2 hours. Insulate for 1 hour, then add 1 part of cross-linking agent N,N-methylenebisacrylamide, stir for 1 hour, then cool down and discharge to obtain water-based acrylate emulsion.

[0040] Then, utilize above-mentioned product aqueous acrylate emulsion to prepare composite type coal dust du...

Embodiment 2

[0043] 45 parts by mass of acrylic acid, 10 parts of butyl acrylate, 5 parts of vinyl acetate, and 6 parts of styrene were mixed in proportion to form a mixed solution for later use. Add 100 parts of water and 3 parts of emulsifier sodium lauryl sulfate into a reaction kettle equipped with a stirrer, a thermometer, a reflux condenser and a feeding device, stir and heat with a water bath. When the temperature rises to 80°C, add 3 parts of 30% hydrogen peroxide as the initiator, and at the same time, drop the above mixed solution from the dropping funnel, control the dropping speed, and complete the dropping within 3 hours. Keep warm for 1 hour, then add 1 part of cross-linking agent ethylene glycol dimethacrylate and divinylbenzene, stir for 1 hour, cool down and discharge to obtain water-based acrylate emulsion.

[0044] Then, utilize above-mentioned product aqueous acrylate emulsion to prepare composite type coal dust dust suppressant:

[0045] Add 100 parts by mass of water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com