Air control system for power take-off with single-h control and its application method

An air control system and power take-off technology, which is applied in the direction of tilt-bearing moving vehicles, etc., can solve the problems of low practicability and can not ensure safe driving power take-off, etc. The effect of safe parking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

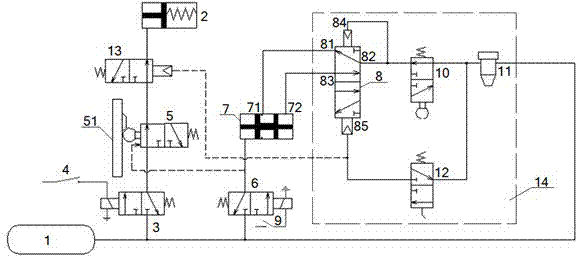

[0044] A single H-operated power take-off pneumatic control system capable of taking power from vehicles, including air reservoir 1, power take-off 2, power take-off solenoid valve 3, power take-off switch 4, low gear control valve 5, parking solenoid valve 6, The middle cylinder 7, the parking switch 9, the high-end shielding valve 13 and the rear auxiliary box single H control system 14. The rear auxiliary box single H control system 14 includes a single H valve 8, a stop valve 10, a pressure limiting valve 11 and a handle control valve 12;

[0045] The air reservoir 1 communicates with the air inlet of the power take-off 2 after passing through the power take-off solenoid valve 3, the low-range control valve 5, and the high-end shielding valve 13 (the air inlet of the power take-off 2 and the control of the power take-off 2 The rod cavity of the cylinder is connected), the output shaft of the power take-off 2 is connected with the gear pump; the air reservoir 1 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com