Jig plate surface automatic change device used for automobile wire harness production line

A technology for automobile wiring harness and jig board, which is applied in the direction of manufacturing tools and workbenches, can solve problems such as affecting work efficiency, wasting manpower, time, and being unsuitable for automated production, and achieves the effect of saving manpower and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

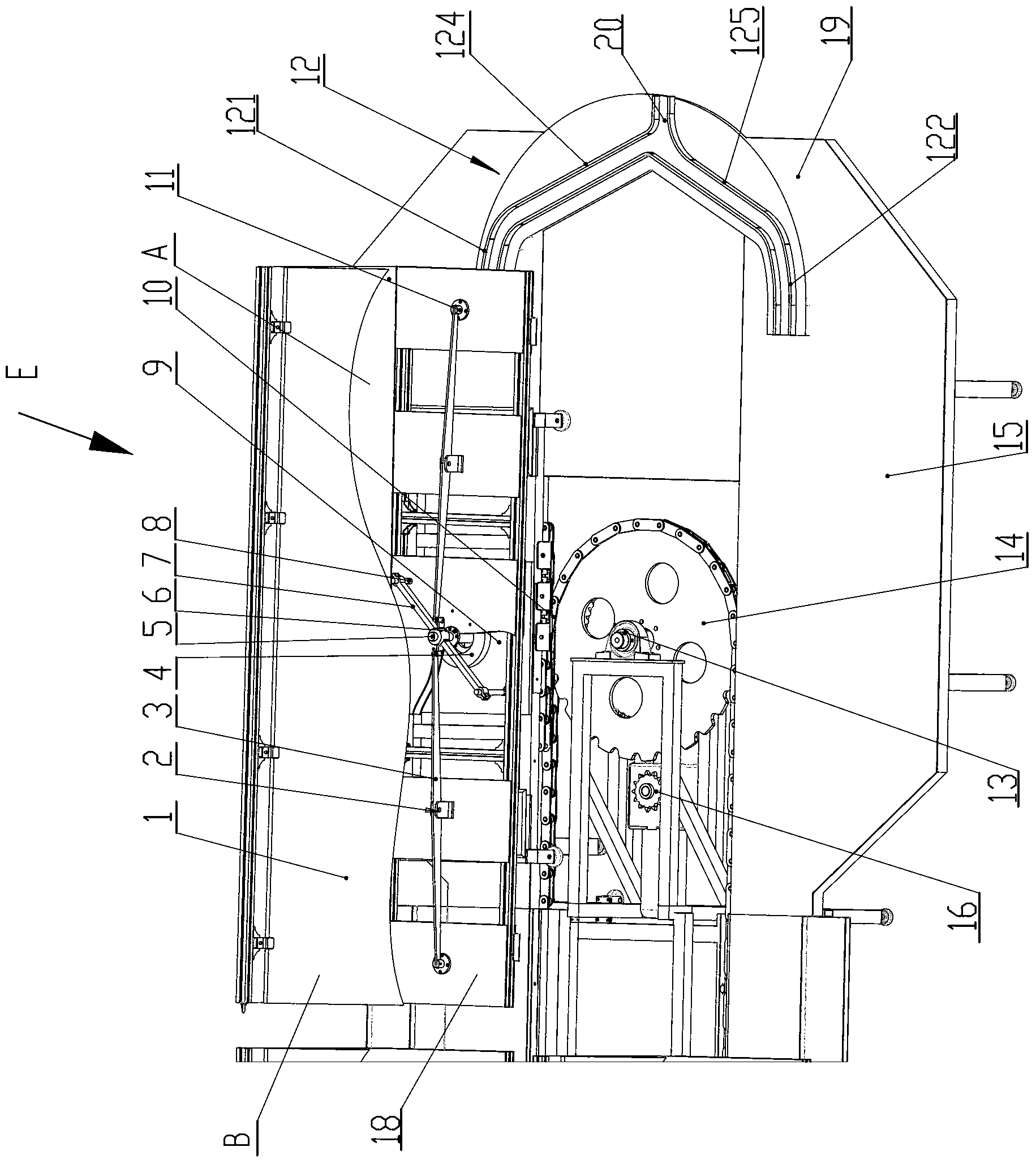

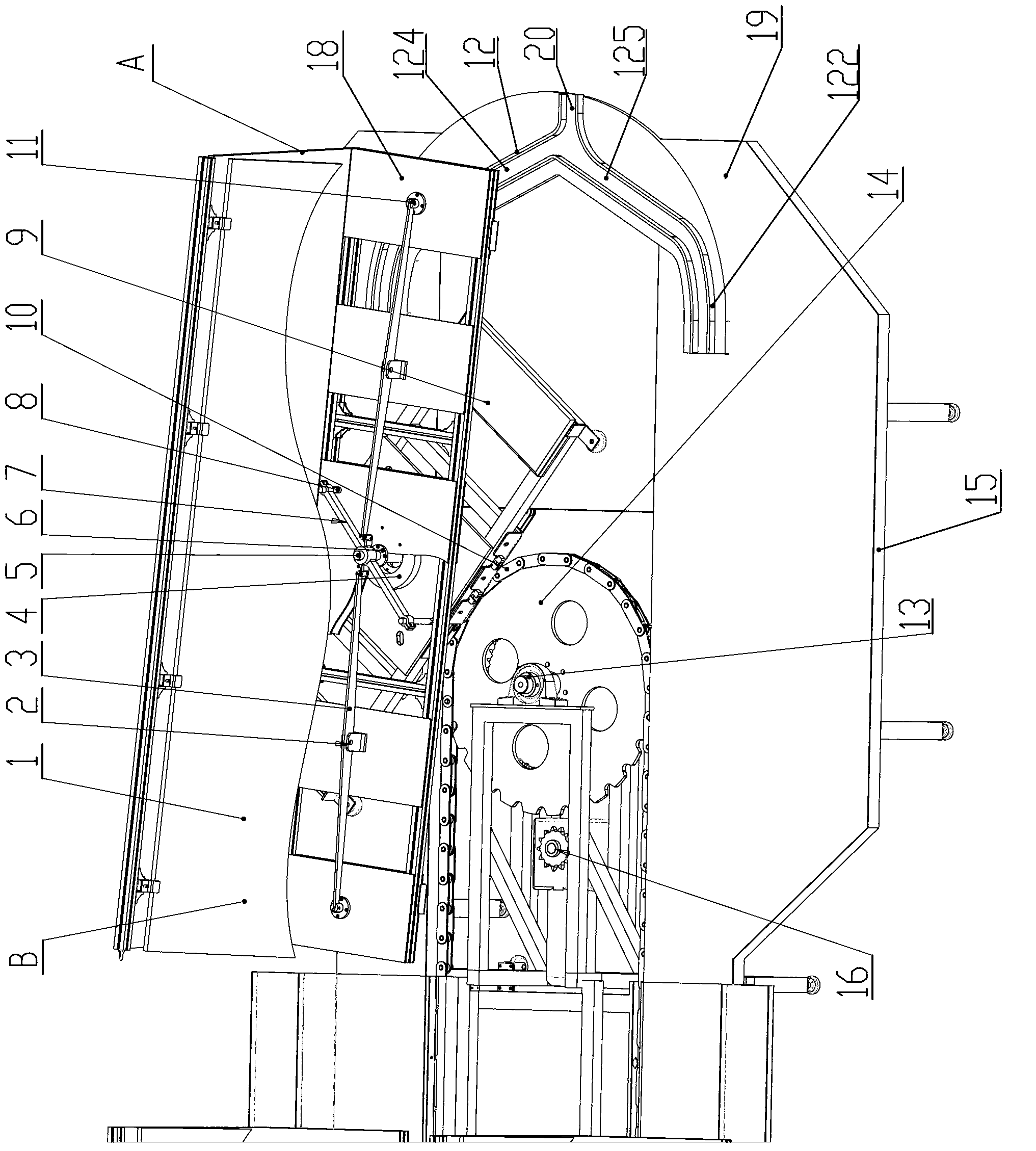

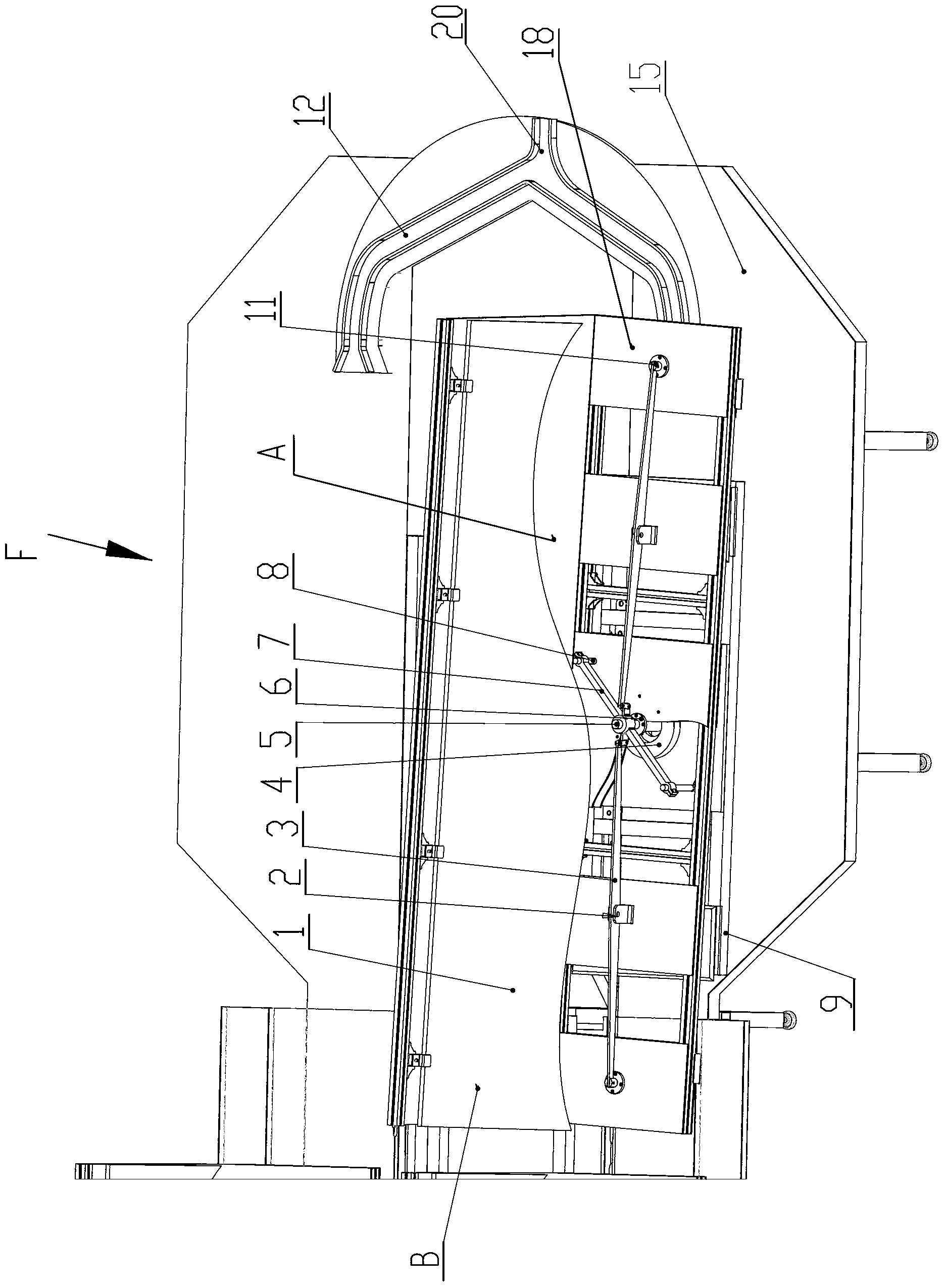

[0020] Figure 1-7 It shows a schematic diagram of the overall structure of an automatic fixture board surface changing device used in the automobile wiring harness production line in different states of pin pulling, surface changing, and locking pins during the surface changing process and its application in the automobile wiring harness production line. Figure 8 It is a structural schematic diagram of the guide chute and the drive sprocket part of the jig plate in the present invention. As shown in the figure, the line body of the above-mentioned production line is provided with a bar-shaped workbench 15, and along the longitudinal centerline 23 of the workbench, horizontally positioned drive sprockets 14 are arranged at its two ends, and a drive sprocket 14 is provided around the drive sprocket 14. The meshed chain 10 and the plurality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com