Grading and branching streaming flotation method of tungsten ore

A branch series flow and flotation technology, applied in flotation, solid separation, etc., can solve the problems of lower flotation index, affect the purity and overall quality of concentrate, and slow flotation rate, so as to improve the separation index and improve The effect of flotation technical indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

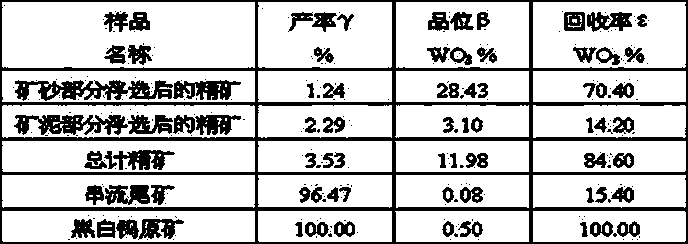

Embodiment 1

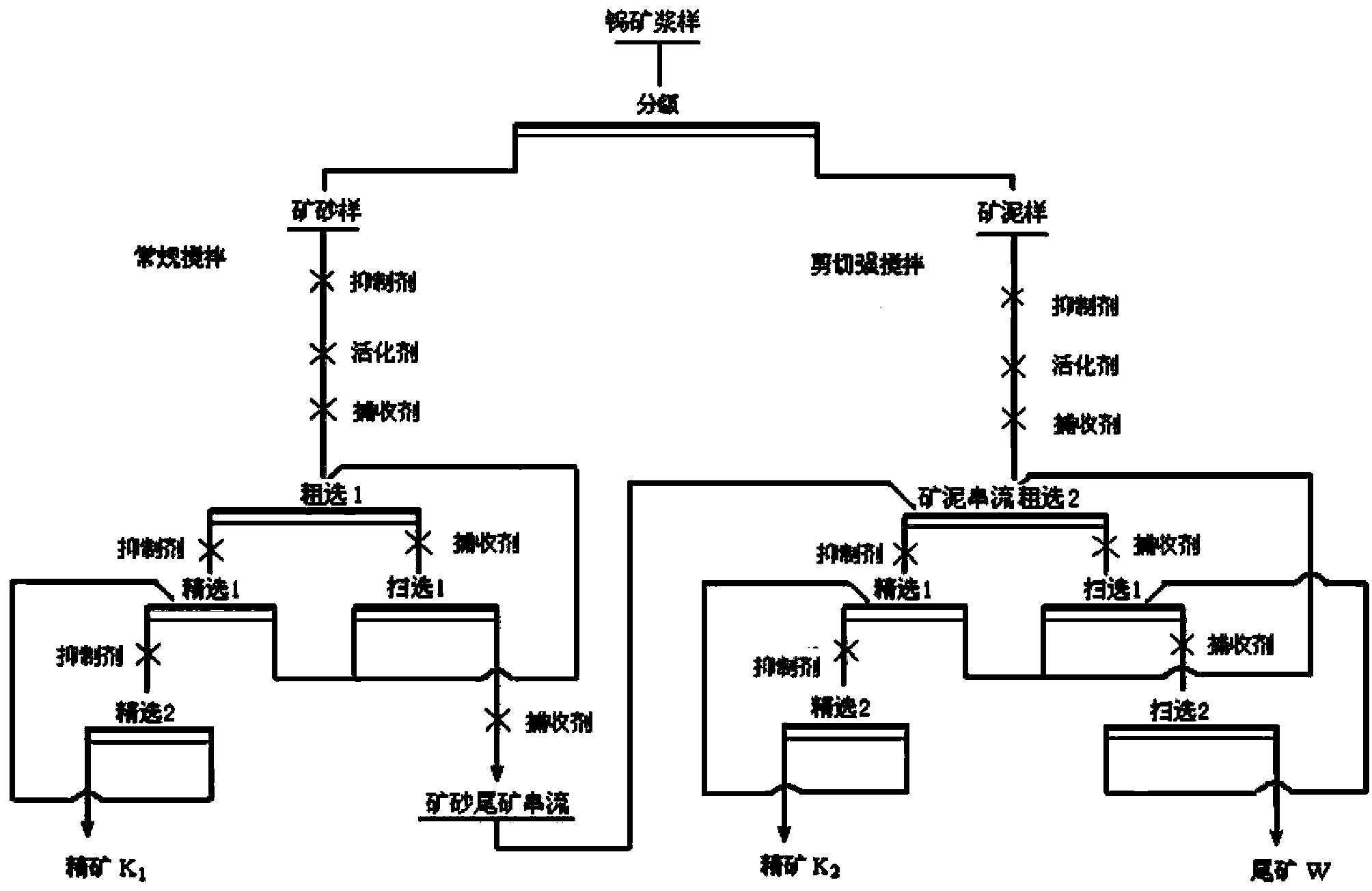

[0035] like figure 1 Shown, the graded branch serial flow flotation method of a kind of tungsten ore of the present invention, it comprises the following steps:

[0036] 1) Firstly, the tungsten ore is finely ground to a particle size smaller than 0.074mm, and the yield accounts for 85%;

[0037] 2) Adjust the finely ground tungsten ore into slurry, and then use hydrocyclone classification equipment to divide it into the ore part with high flotation speed and the slime part with low flotation speed. The yield of the ore part is 95%, and the ore part is The particle size is 0.10mm; the slime yield is 5%, and the particle size of the slime part is 0.010mm;

[0038] 3) Auxiliaries need to be added before partial flotation of ore and a conventional mixer is used. Auxiliaries include water glass 2800g / t, aluminum sulfate 550g / t, activator lead nitrate 500g / t, chelating collector 300g / t, fatty acid Collector 45 / t, water glass and aluminum sulfate stirring time of the present inven...

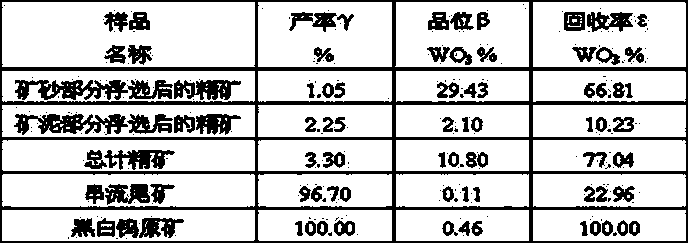

Embodiment 2

[0043] A kind of graded branch series flow flotation method of tungsten ore of the present invention, it comprises the following steps:

[0044] 1) First, the tungsten ore is finely ground to a particle size smaller than 0.074mm, and the yield accounts for 95%;

[0045] 2) Adjust the finely ground tungsten ore into slurry, and then use hydrocyclone classification equipment to divide it into the ore part with high flotation speed and the slime part with low flotation speed. The yield of the ore part is 55%, and the ore part The particle size is 0.10mm; the slime yield is 45%, and the particle size of the slime part is 0.001mm;

[0046] 3) Auxiliaries need to be added before partial flotation of ore and a conventional mixer is used. Auxiliaries include water glass 3500g / t, aluminum sulfate 300g / t, activator lead nitrate 700g / t, chelating collector 500g / t, fatty acid Collector 20 / t, water glass and aluminum sulfate stirring time of the present invention need about seven minutes,...

Embodiment 3

[0051] A kind of graded branch series flow flotation method of tungsten ore of the present invention, it comprises the following steps:

[0052] 1) First, the tungsten ore is finely ground to a particle size smaller than 0.074mm, and the yield accounts for 75%;

[0053] 2) Adjust the finely ground tungsten ore into slurry, and then use hydrocyclone classification equipment to divide it into the ore part with high flotation speed and the slime part with low flotation speed. The yield of the ore part is 70%, and the ore part The particle size is 0.10mm; the slime yield is 30%, and the particle size of the slime part is 0.01mm;

[0054] 3) Auxiliaries need to be added before partial flotation of ore and a conventional mixer is used. Auxiliaries include water glass 1500g / t, aluminum sulfate 700g / t, activator lead nitrate 300g / t, chelating collector 200g / t, fatty acid Collector 80 / t, water glass and aluminum sulfate stirring time of the present invention need about seven minutes, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com