LED backlight driving circuit, driving method of LED backlight driving circuit and liquid crystal display device

A technology of backlight driving circuit and LED light bar, applied in static indicators, instruments, etc., can solve the problems of not being able to provide short-circuit protection for LED light bars, and the inability to identify LED backlight driving circuits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

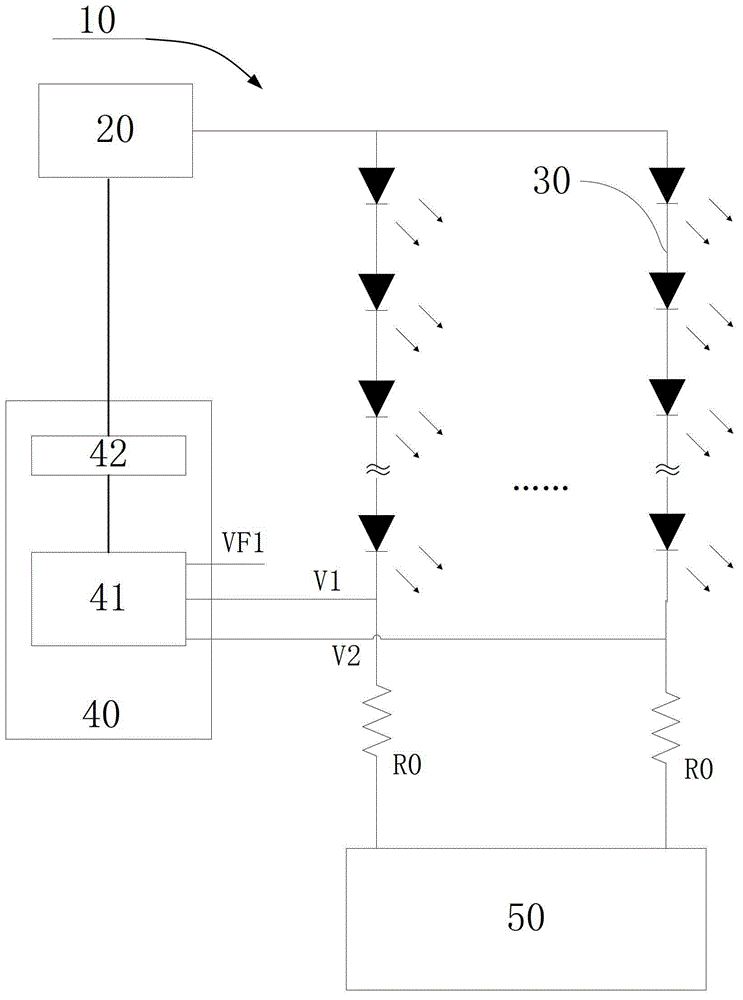

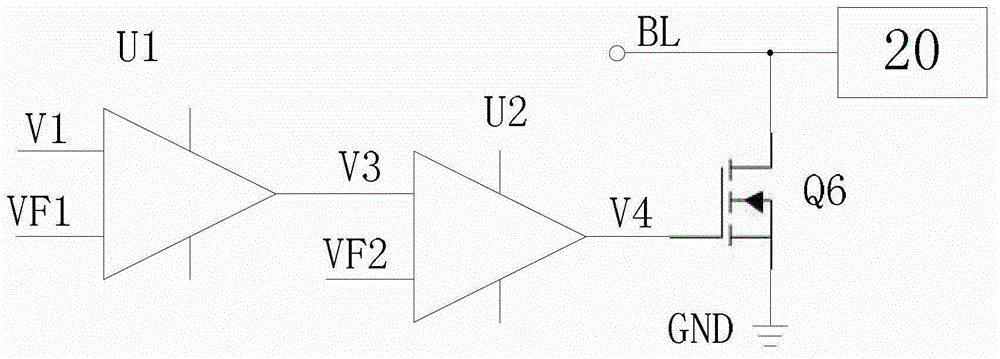

[0058] like figure 1 , 2 As shown, the comparison unit in this embodiment includes a subtractor U1, a first input terminal of the subtractor U1 is coupled to the feedback voltage V1; a second input terminal thereof is coupled to the first reference voltage VF1. The difference between the feedback voltage and the first reference voltage VF1 can be directly output through the subtractor U1, so that the subsequent drive unit only needs to judge whether the difference exceeds a preset deviation value, and if it exceeds, the drive power supply module is turned off.

[0059] The driving unit includes a comparator U2, the first input terminal of the comparator U2 is coupled to the output terminal of the subtractor U1; the second input terminal of the comparator U2 is coupled with a second reference voltage VF2;

[0060] The second reference voltage VF2 is equal to the preset deviation value, and when the output voltage of the subtractor U1 is greater than the second reference voltag...

Embodiment 2

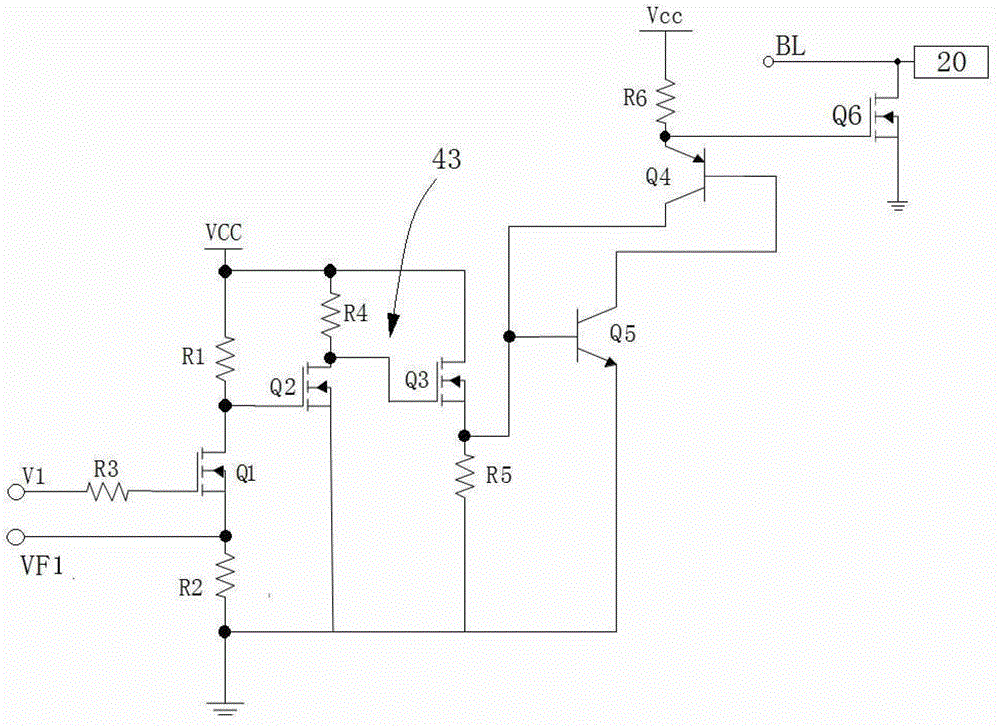

[0064] like figure 1 , 3 As shown, the comparison unit in this embodiment includes a first controllable switch Q1, a first resistor R1, a second resistor R2 and a third resistor R3; the source of the first controllable switch Q1 is coupled to A reference high-level signal VCC, the drain of which is coupled to the ground terminal of the LED backlight drive circuit through the second resistor R2; the feedback voltage V1 is coupled to the gate of the first controllable switch Q1 through the third resistor R3; the second A reference voltage VF1 is coupled to the drain of the first controllable switch Q1; the source of the first controllable switch Q1 is also coupled to an inverter 43, and the output terminal of the inverter 43 is coupled to the drive unit ;

[0065] The inverter 43 includes a second controllable switch Q2, a third controllable switch Q3, a fourth resistor R4, and a fifth resistor R5;

[0066] The source of the second controllable switch Q2 is coupled to the ref...

Embodiment 3

[0077] like Figure 4 Shown, a kind of driving method of LED backlight driving circuit, described LED backlight driving circuit comprises LED light bar, drives the power supply module of LED light bar, and described driving method comprises steps:

[0078] A: Connect the voltage dividing resistor R0 in series at the output end of the LED light bar; preset the first reference voltage VF1 and the deviation value;

[0079] The first reference voltage VF1 is greater than or equal to the maximum voltage at both ends of the divider resistor R0 when the normal LED light bar is at maximum brightness;

[0080] B: The voltage at both ends of the voltage dividing resistor R0 is compared with the first reference voltage VF1 as a feedback voltage, and if the difference between the feedback voltage and the first reference voltage VF1 exceeds a preset deviation value, the power supply module is controlled to be turned off.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com