An array deployment device for integral puncture steel needles

An integral puncture and steel needle technology, which is used in deburring devices, textiles and papermaking, fiber processing, etc., can solve the problems of inability to use super-long steel needles for placement, and cannot meet the overall puncture process, reducing labor intensity and improving. The degree of automation, the effect of achieving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in combination with specific embodiments.

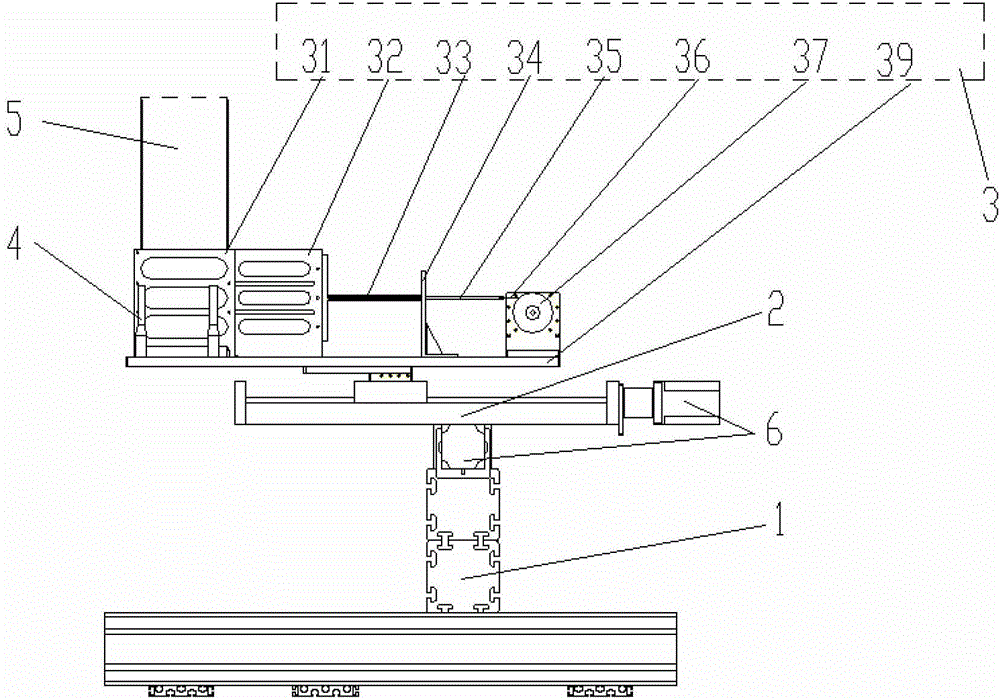

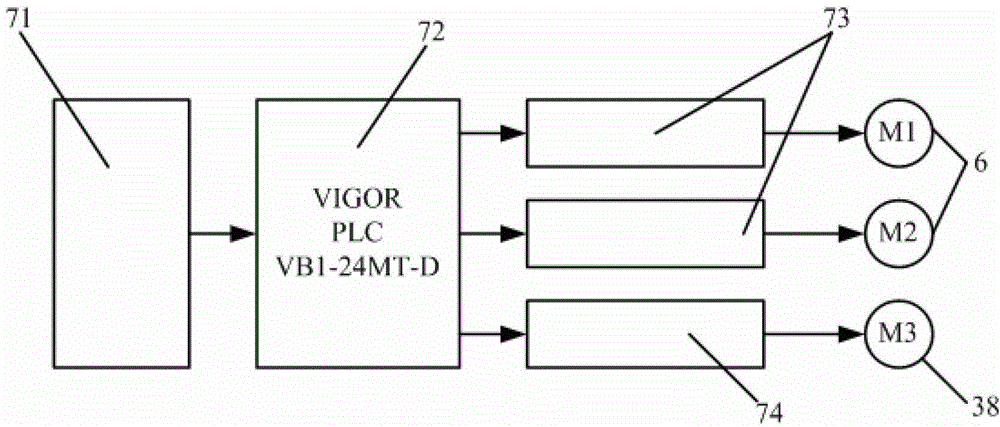

[0028] Such as figure 1 As shown, a whole puncture steel needle array deployment device of the present invention includes a control system, multiple cross lasers 4 and a frame 1 with a workbench, the frame 1 is provided with an X-Y mobile platform 2, and the The X-Y mobile platform is provided with a puncture needle deployment mechanism 3; the X-Y mobile platform 2 includes two sets of orthogonal linear modules, and the linear modules are driven by an AC servo motor 6 fixed on the connecting flange through a shaft coupling.

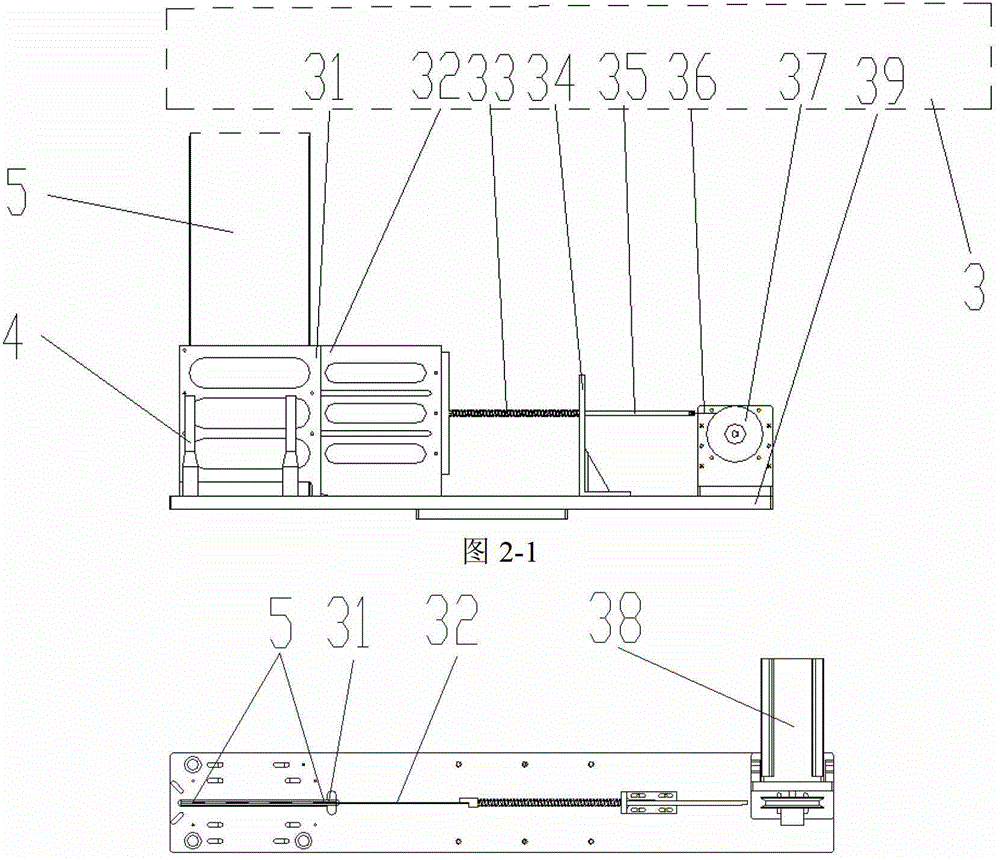

[0029] Such as figure 1 with diagram 2-1 As shown, the puncture needle deployment mechanism 3 includes a base plate 39, the base plate 39 is fixed on the slider of the X-Y mobile platform 2, and one end above the base plate 39 is provided with a closed-loop stepping motor 38, and the closed-loop stepping motor The output end of the motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com