Liquid consumption device and method

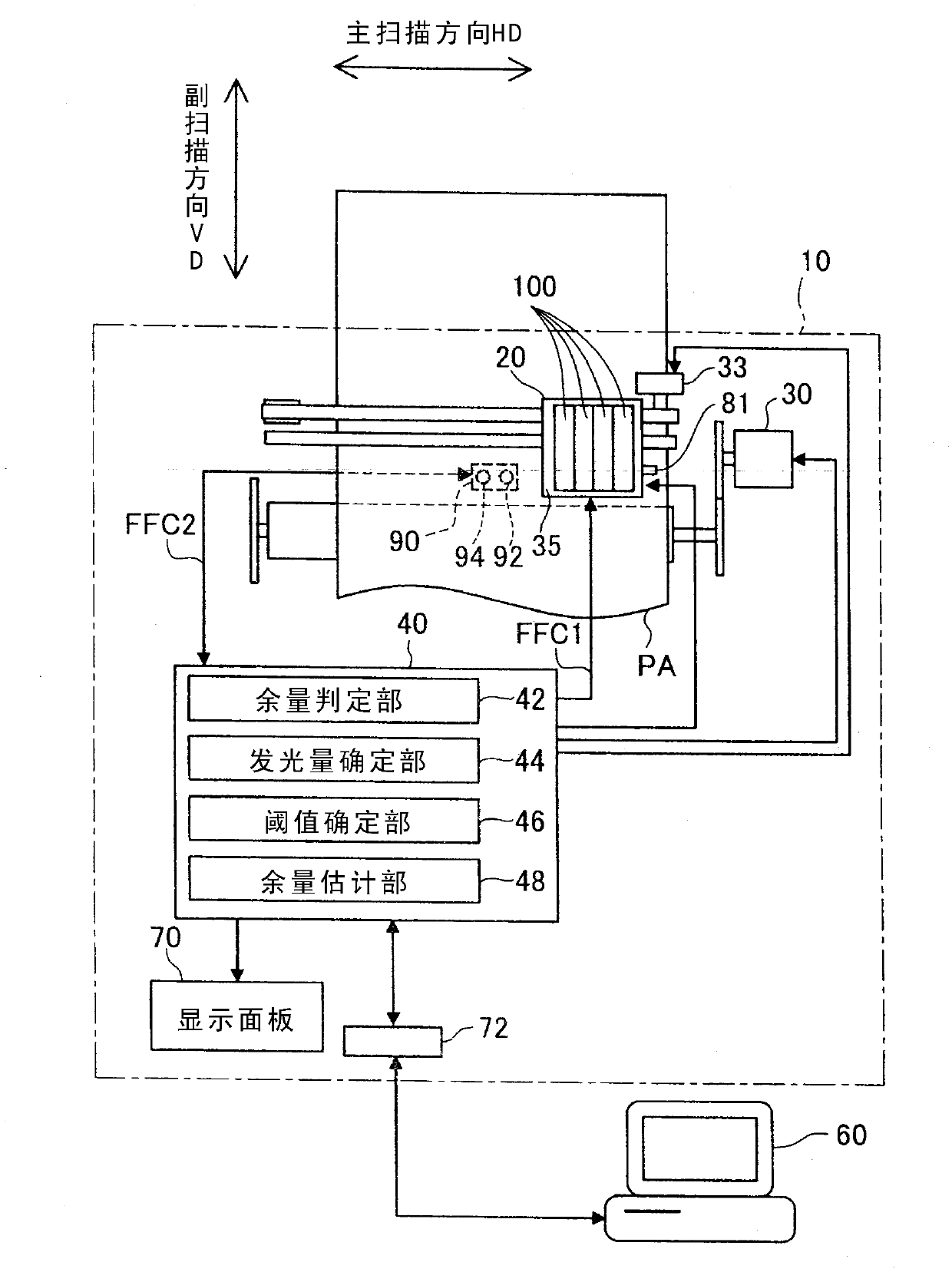

A liquid consumption device, liquid technology, applied in printing and other directions, can solve problems such as error expansion, inability to correctly detect ink remaining state, and decrease in reflected light quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Deformed example 1

[0164] exist Figure 12 In the threshold determination processing shown, the threshold is calculated based on the bottom value corresponding to the light emission amount determined by the light emission amount determination processing. On the other hand, for example, the output voltage of the detection unit 90 corresponding to the reflected light from the reflector 81 may be set to a predetermined voltage, and the amount of light emitted from the light emitting unit 92 may be set to measure the amount of light emitted. Corresponding to the valley value to calculate the threshold. That is, the bottom value determined by the light emission amount determination processing and the bottom value used as the calculation reference of the threshold value in the threshold value determination processing may be different bottom values.

Deformed example 2

[0166] In the above-described embodiment, the light shielding film 50 is provided on the central portion of the bottom surface of the prism 170, but the light shielding film 50 may be omitted. In this case, for each ink cartridge 100, it is available at one location instead of two Figure 7 Valley values shown.

Deformed example 3

[0168] In the above-described embodiments, the higher the amount of received light, the lower the output voltage of the detection unit 90 . On the other hand, the voltage output from the detection unit 90 may be increased as the amount of received light increases. In this case, all the “bottom values” described as the lowest output voltage of the detection unit 90 in the above-described embodiments can be understood as the highest “peak values” of the output voltage of the detection unit 90 . In addition, in this case, the above formula (1) can be expressed as the following formula (1b).

[0169] V2=V1×(PD2 / PD1)×(Vref2 / Vref1)…(1b)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com