Axial vernier device for lens with flexible ring piece structure

A technology of fine-tuning device and flexible ring, which is applied in the direction of photolithography exposure device, installation, micro-lithography exposure equipment, etc., can solve the problems of low adjustment accuracy, small carrying capacity, small adjustment stroke, etc., and achieve real-time adjustment ability, large Bearing capacity, effect of compensating tilt error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

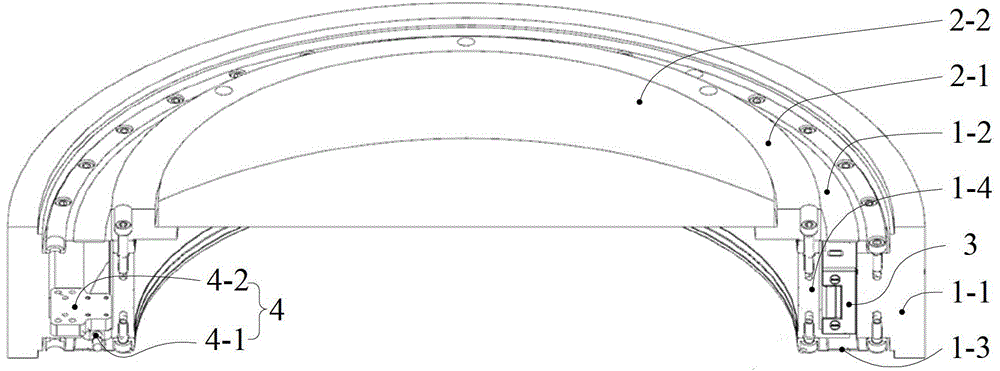

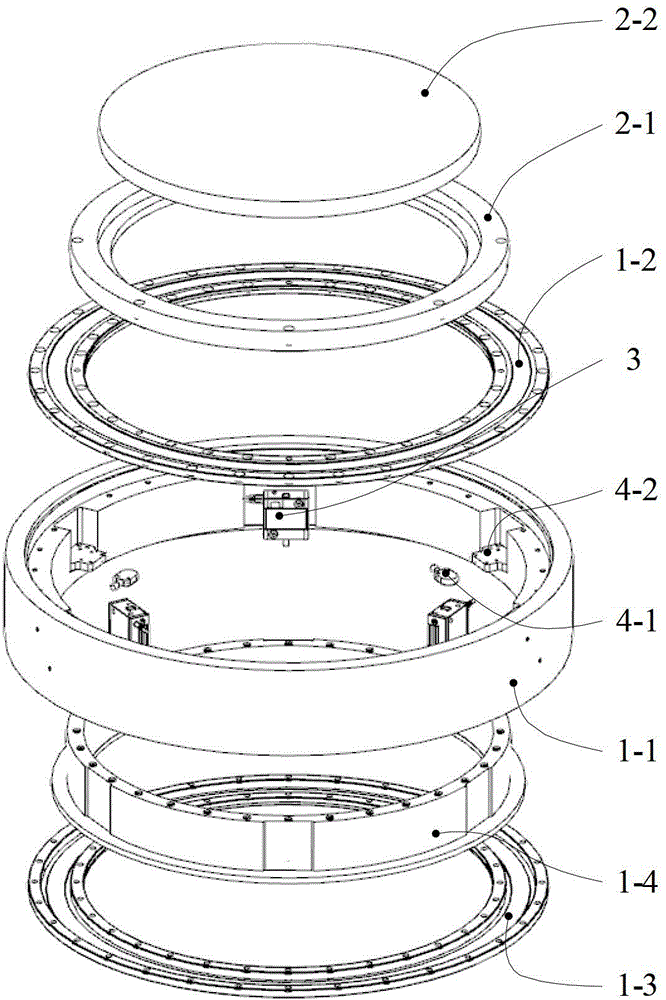

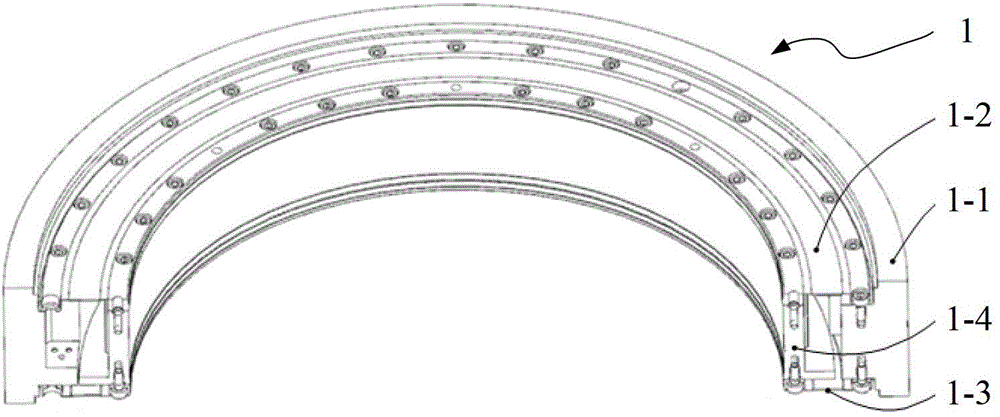

[0025] See attached figure 1 And attached figure 2 A lens axial fine-tuning device with a flexible ring structure of the present invention includes an axial fine-tuning assembly 1, a lens assembly 2, three micro-displacement drivers 3 and three micro-displacement sensor assemblies 4; the lens assembly 2 includes a mirror frame 2 -1 and lens 2-2, the micro-displacement sensor assembly 4 includes a micro-displacement sensor 4-1 and a sensor connecting plate 4-2, and the axial fine-tuning assembly 1 includes a lens barrel 1-1, an upper flexible ring sheet 1-2, The lower flexible ring sheet 1-3 and the driving ring 1-4; this device is for adjusting the axial relative position of the lens 2-2. The lens barrel 1-1 is the basis for the installation of the whole fine-tuning device, the lens barrel 1-1 and the upper flexible ring piece 1-2, the lower flexible ring piece 1-3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com