Universal liquid concentration supersonic-detection method and universal liquid concentration supersonic-detection device

A liquid concentration, detection device technology, applied in measurement devices, material analysis using sonic/ultrasonic/infrasonic waves, instruments, etc., can solve the problems of large data storage, external interference and false detection, temperature influence, etc., to achieve detection accuracy High, simple structure and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

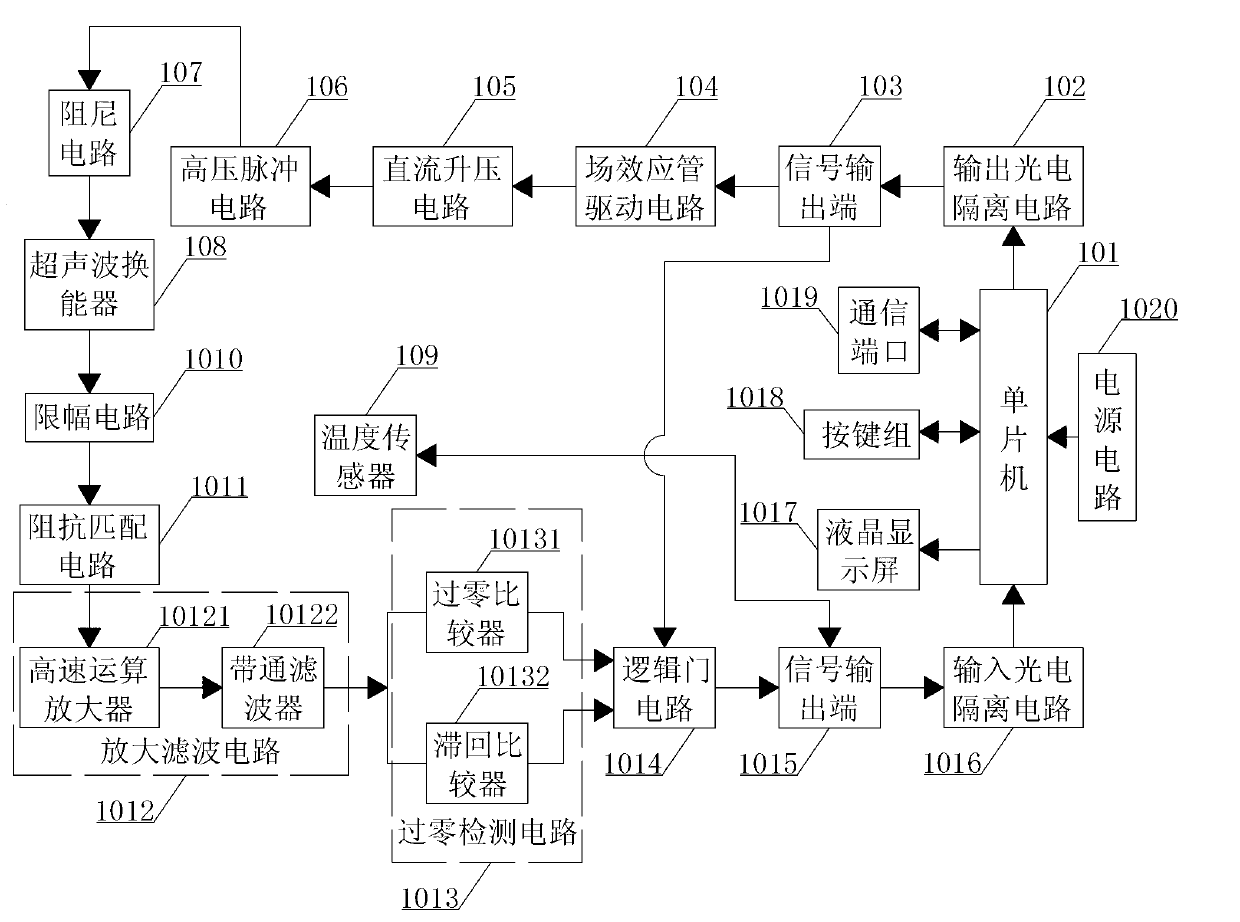

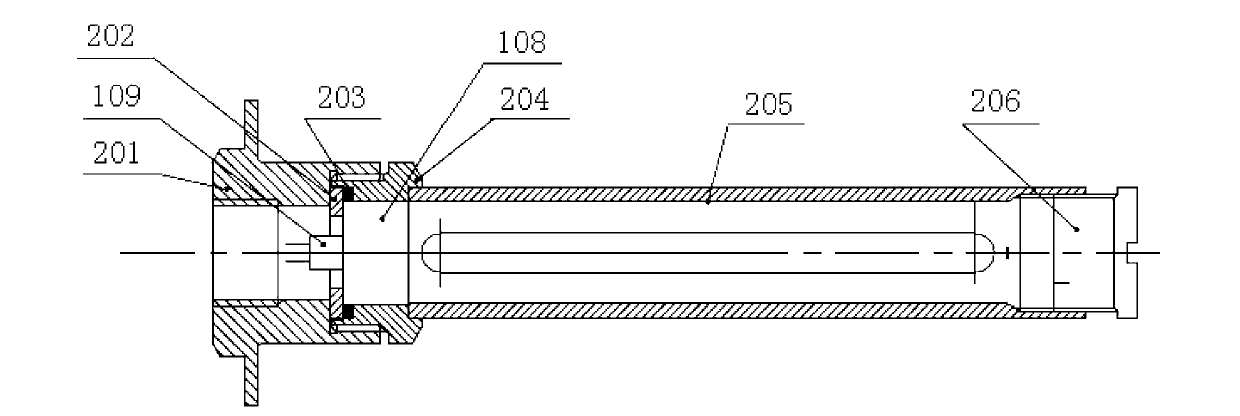

Embodiment Construction

[0028] The present invention will be further described below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, the drawings only show some but not all of the contents related to the present invention.

[0029] In this embodiment, the general-purpose ultrasonic liquid concentration detection method specifically includes the following steps:

[0030] Step S101, performing acoustic time sampling for different solvents and solutes at different temperature points, and analyzing the sampling results to obtain the corresponding relationship between acoustic time and temperature and solution concentration, wherein the acoustic time refers to the ultrasonic wave in a fixed sound path. on the propagation time.

[0031] Since the speed of sound i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com