Industrialized assembly type special-shaped column steel structure frame-eccentric support system

A technology of steel structure frame and industrialized assembly, applied in the direction of building structure, construction, etc., can solve problems such as brittle failure of rigid beam-column joints, and achieve the effect of reducing fire, avoiding environmental pollution, and increasing clear height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention is described in detail below in conjunction with accompanying drawing:

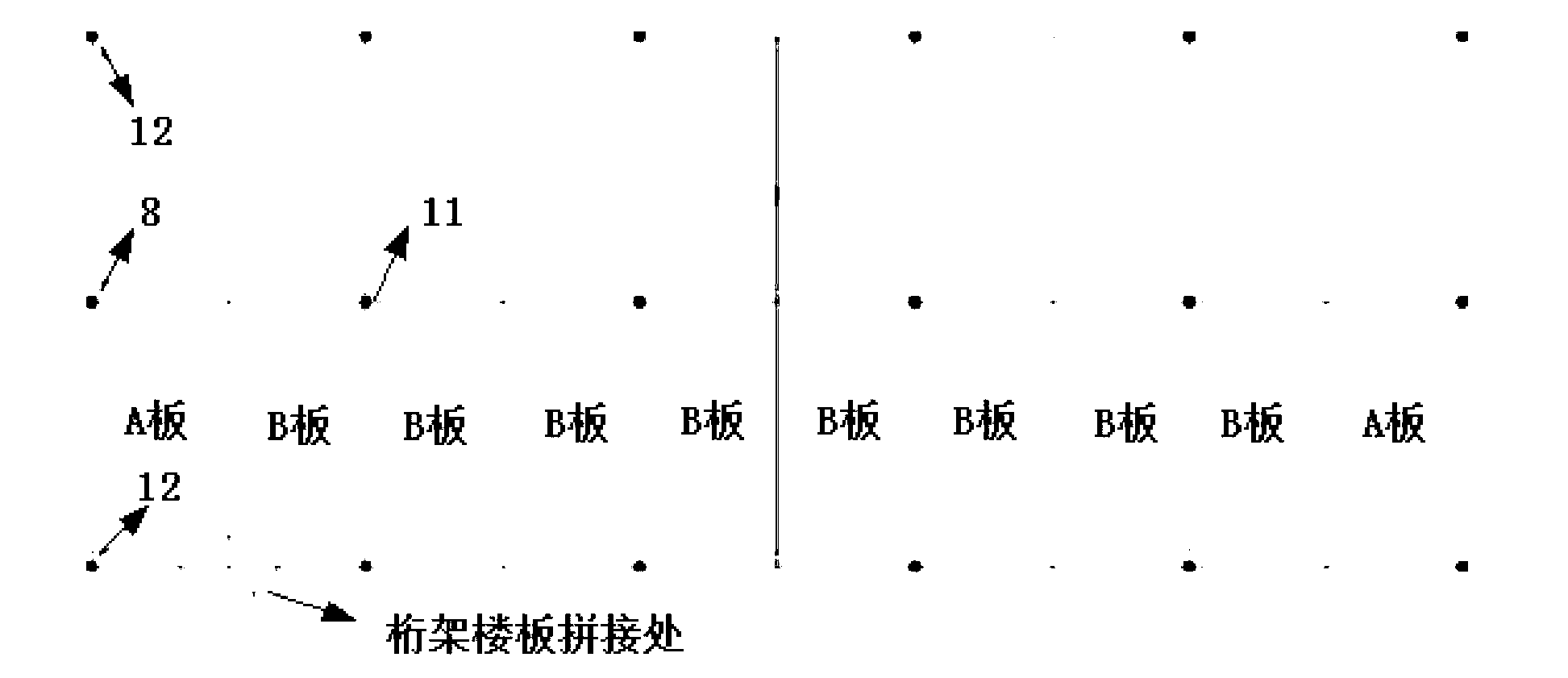

[0057] as attached figure 1 As shown, the assembled truss plate of the present invention is spliced with the assembled column in the manner of ABB···BBA.

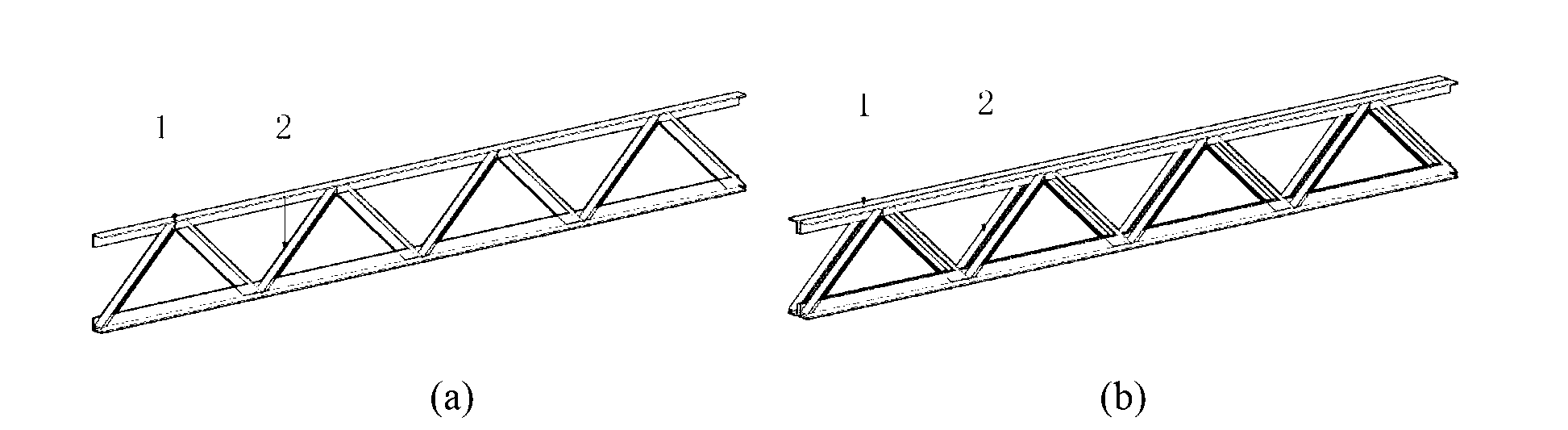

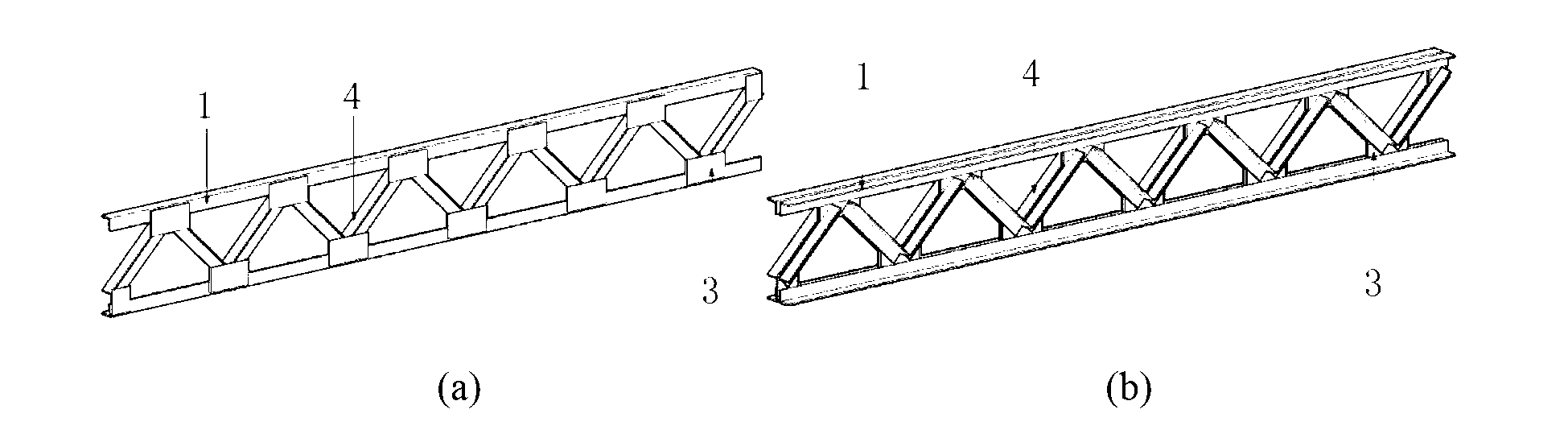

[0058] as attached Figure 4 As shown, in the industrialized assembled special-shaped column steel structure frame-eccentric support frame system described in the present invention, the involved beam is a truss beam composed of channel steel and angle steel splicing, including upper and lower chords 5 and webs 4, wherein the upper and lower The chord 5 is made of channel steel, and the web 4 is made of angle steel, which is divided into single-channel steel beams and double-channel steel beams. The single-channel steel beams are provided with connecting holes at intervals of a fixed distance, so that the two pieces can be bolted together when the plates are spliced. Single-channel steel beams are spliced into double-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com