Butt-joint adjusting device of steel bar cage

A technology for adjusting devices and reinforcing cages, which is applied in the directions of transportation and packaging, load hanging elements, etc., to achieve the effects of convenient disassembly, enhanced stability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

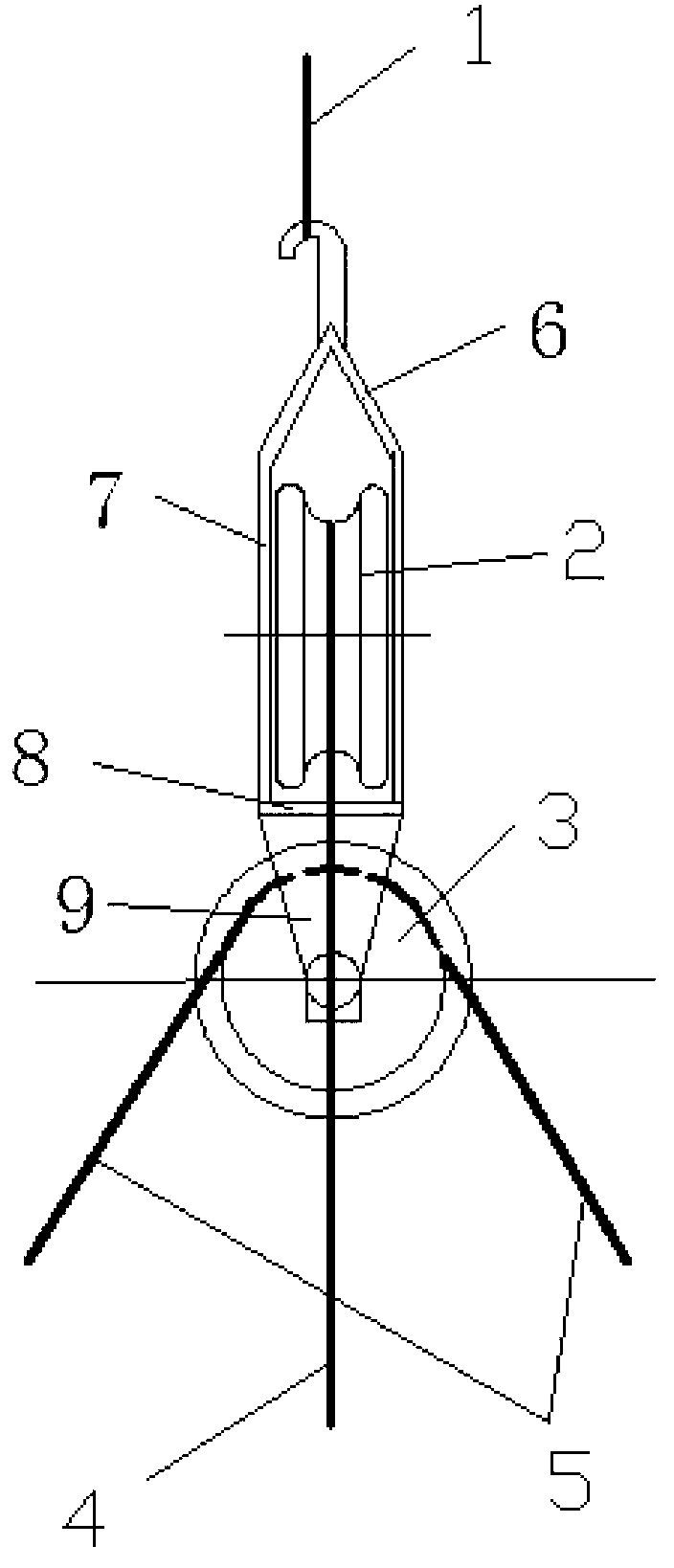

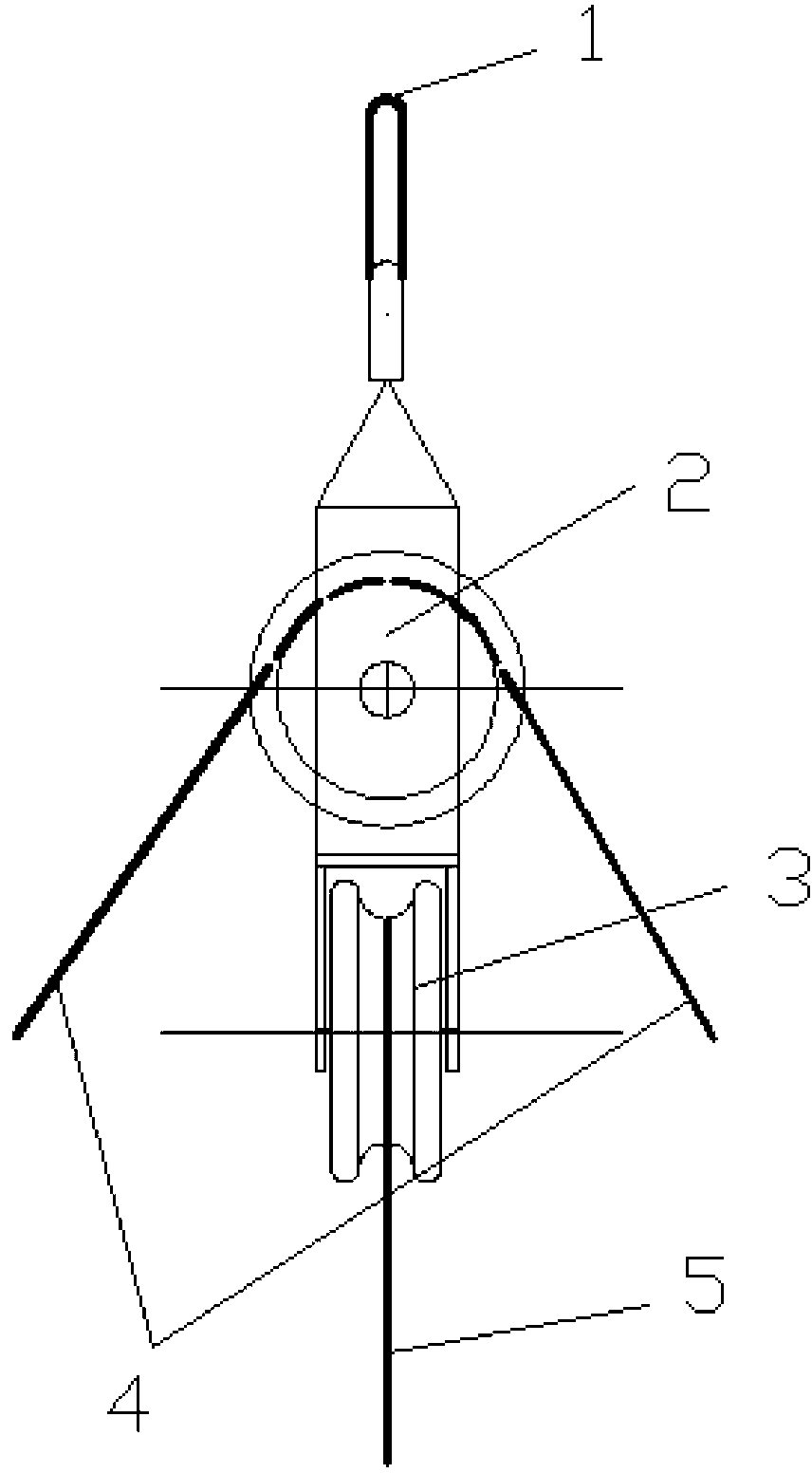

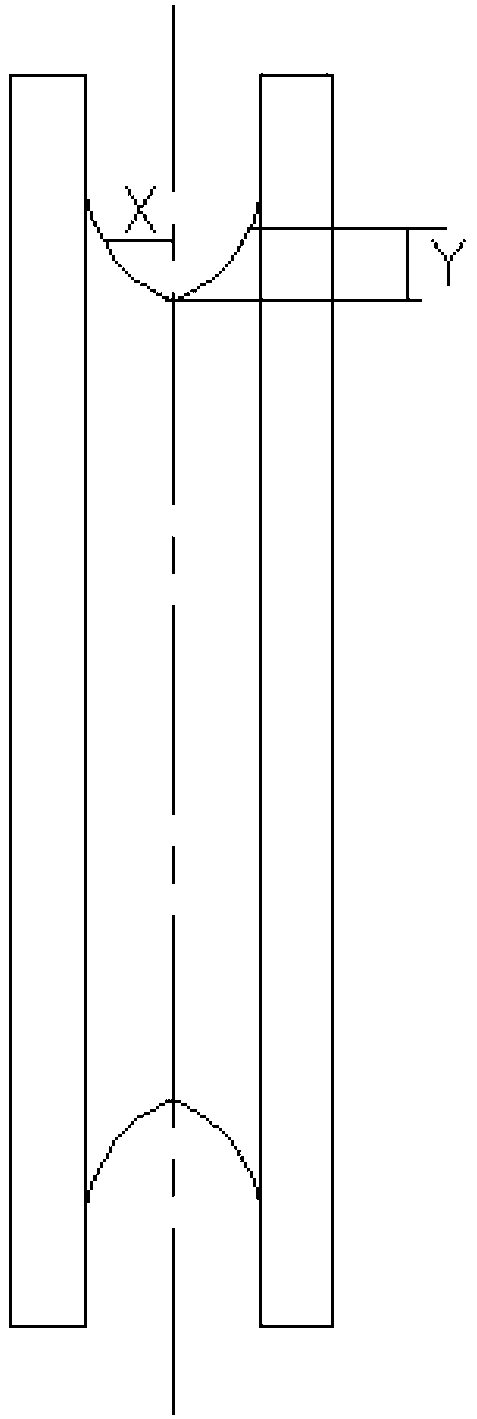

[0027] Such as figure 1 , figure 2 and image 3 As shown, a steel cage docking adjustment device includes a first pulley 2, a hook, a second pulley 3, and a pulley fixing device. The hook is arranged on the top of the pulley fixing device, and the pulley fixing device is sequentially provided with inclined Plate 6, the first vertical plate 7, connecting plate 8, the second vertical plate 9; There are two inclined plates 6, and the two inclined plates 6 form an inverted V-shaped structure; the angle between the two inclined plates 6 can be 45-60°, within this range, the slant plate 6 is the safest, if the angle is too large and the weight of the hoisted steel cage is too large, the connection between the two slant plates 6 is easy to be torn apart, resulting in Scrapping of the entire device; if the angle is too small, the length of the slant plate 6 needs to be lengthened, resulting in waste of resources. This embodiment preferably selects 45°, which saves the most material...

Embodiment 2

[0031] Same as embodiment 1, the difference is that the angle between the two inclined plates 6 is 50°, and the radius R of the first pulley steel wire 4 is 4mm.

Embodiment 3

[0033] Same as embodiment 1, the difference is that the angle between the two inclined plates 6 is 60°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com