Closed loop testing method of power plant side automatic voltage control system

A closed-loop testing and control system technology, applied in the direction of electrical testing/monitoring, etc., can solve the problems of economical operation of the power system and the far-reaching goals of reliable power supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

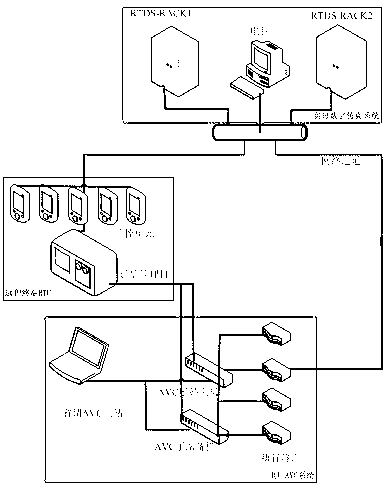

Image

Examples

Embodiment 1

[0043]Embodiment 1. Pulse width setting test of the reactive power regulating device of the unit: This test is one of the parameter setting tests. In this test, important parameters such as unit signal output interval, maximum signal width, minimum signal width and slope in "reactive power output setting" are set by adjusting the output pulse width of the AVC substation, so as to accumulate experience for field tests and parameter tuning.

Embodiment 2

[0044] Embodiment 2. Reactive power distribution adjustment performance test between units: This test is one of the basic function tests. Set the "busbar voltage regulation" mode of the AVC system to test the rationality of the reactive power distribution of each unit during the adjustment process of the AVC substation, that is, test four distribution methods, such as: equal power factor reactive power distribution, equal margin reactive power distribution , equal-capacity reactive power distribution, reactive power average distribution, and check the distribution effect of various reactive power distribution methods.

Embodiment 3

[0045] Embodiment 3. Unit reactive power reverse modulation test: This test is one of the basic function tests. Test the ability of the AVC system to adjust the reactive power out-of-limit inversion and allocate the reactive power reasonably. First set the "busbar voltage regulation" mode, the master station sends an instruction to demagnetize until the reactive power of the unit exceeds the lower limit, and check the reactive power reverse regulation process of the AVC sub-station device. Or, the master station sends an instruction to increase the magnetization until the reactive power of the unit exceeds the upper limit, and check the reactive power inversion process of the AVC sub-station device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com