Light source module

A light source module and light collection technology, applied in the field of optical devices, can solve the problem of low brightness and achieve the effect of high collimation and high forward brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

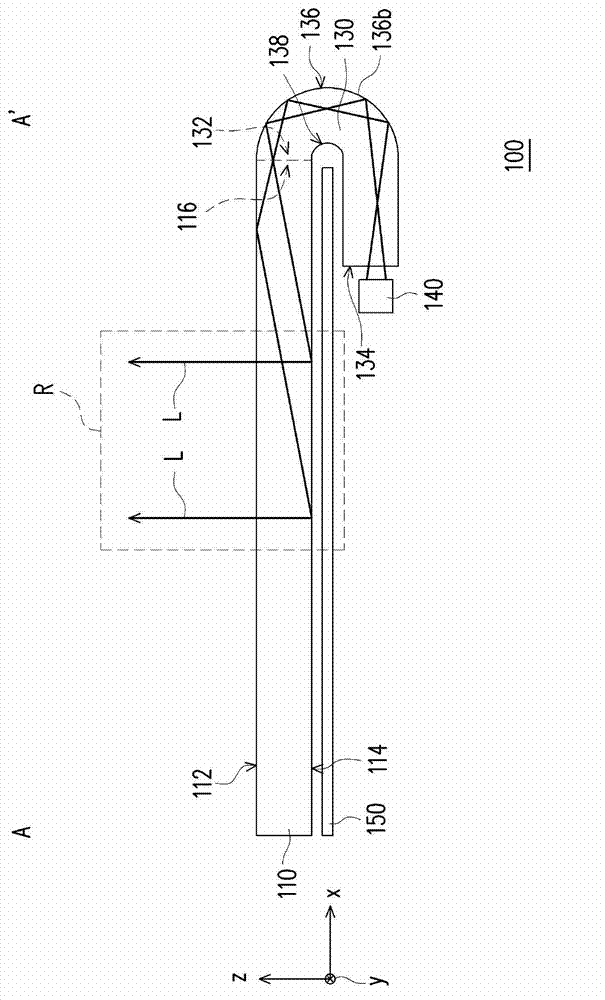

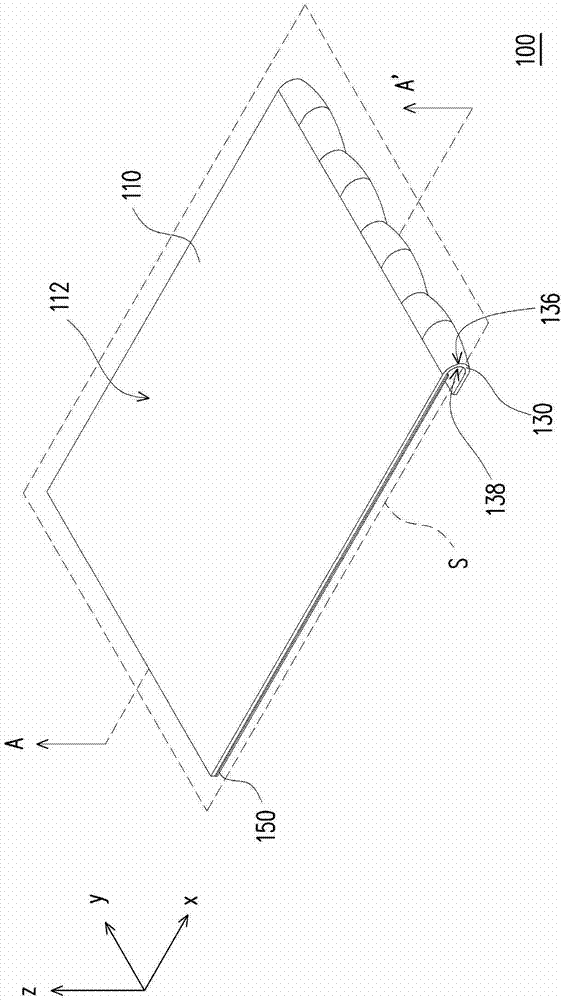

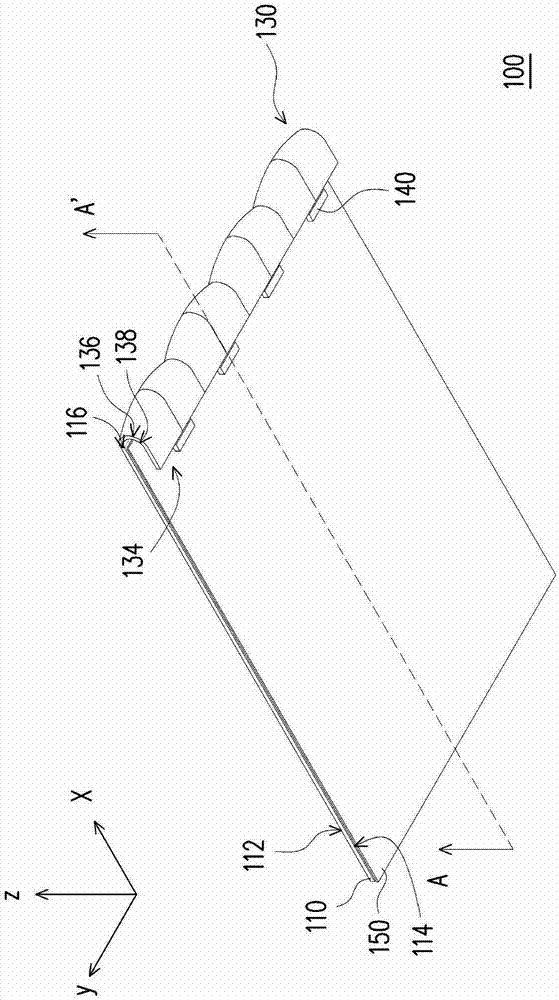

[0081] figure 1 It is a schematic cross-sectional view of the light source module according to the first embodiment of the present invention. figure 2 for figure 1 Stereoscopic view of the light source module. image 3 for figure 1 Stereoscopic view of the light source module. especially, figure 1 yes figure 2 and image 3 Schematic cross-sectional view along section line AA'. Please refer to figure 1 , figure 2 and image 3 , the light source module 100 of this embodiment includes a light guide plate 110 , at least one light collecting structure 130 and at least one light emitting element 140 . figure 2 and image 3 Four light-collecting structures 130 and four light-emitting elements 140 are shown as representatives. One light-collecting structure 130 corresponds to one light-emitting element 140. However, the present invention does not limit the number of light-collecting structures 130 and light-emitting elements 140. The numbers of light-collecting structu...

no. 2 example

[0093] Figure 10 It is a schematic cross-sectional view of the light source module according to the second embodiment of the present invention. Figure 11 for Figure 10 Stereoscopic view of the light source module. Figure 12 for Figure 10 Stereoscopic view of the light source module. especially, Figure 10 With Figure 11 and Figure 12 Schematic cross-sectional view along section line BB'. Please refer to Figure 10 , Figure 11 and Figure 12 , the light source module 100B of this embodiment is similar to the light source module 100 of the first embodiment, so the same components are denoted by the same reference numerals. The main difference between the light source module 100B of this embodiment and the light source module 100 of the first embodiment is that the light collection structure 130B of this embodiment is different from the light collection structure 130 of the first embodiment. In addition, the light source module 100B of this embodiment further i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com