Disc type maize breeding slicer

A corn breeding and slicing machine technology, applied in metal processing and other directions, can solve the problems of heavy tasks, time-consuming and manpower, etc., and achieve the effects of reducing manual labor, improving cutting efficiency, and improving labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

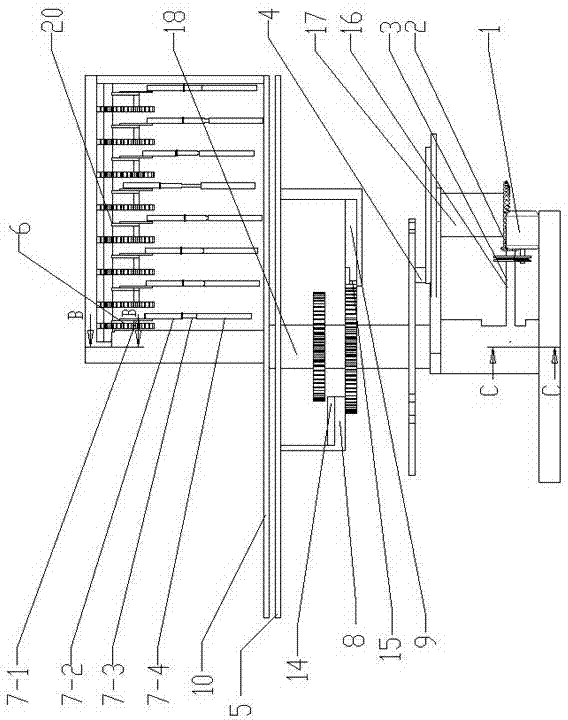

[0014] Such as figure 1 , 2 , Shown in 3, a kind of disc type corn breeding slicer comprises working disc 10, fixed disc 5, driving mechanism, cutting mechanism 7, sheave mechanism 4.

[0015] The drive mechanism is a motor 1 placed horizontally, and the motor is connected with a horizontal transmission shaft 16 through a belt drive 3 . The horizontal transmission shaft 16 is connected with the working disc through the bevel gear transmission 2, the vertical transmission shaft 17, the sheave mechanism 4 and the vertical transmission shaft 18; Station 10-1, cutting station 10-2, intermediate station 10-3 and blanking station 10-4, all four stations are equipped with material holes 11; the material holes of the cutting station pass through the hose and the endosperm material The tray 9 communicates, and the material hole of the blanking station communicates with the seed tray 8 through a hose channel. The vertical transmission shaft 18 is respectively connected with the seed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com