Low-permeability coal high-pressure gas cycle pulse fracturing anti-reflection experimental method

A high-pressure gas, circulating pulse technology, applied in permeability/surface area analysis, measurement device, suspension and porous material analysis, etc., can solve the problems of insignificant anti-reflection effect, limited anti-reflection range, and difficult to discharge high-pressure water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

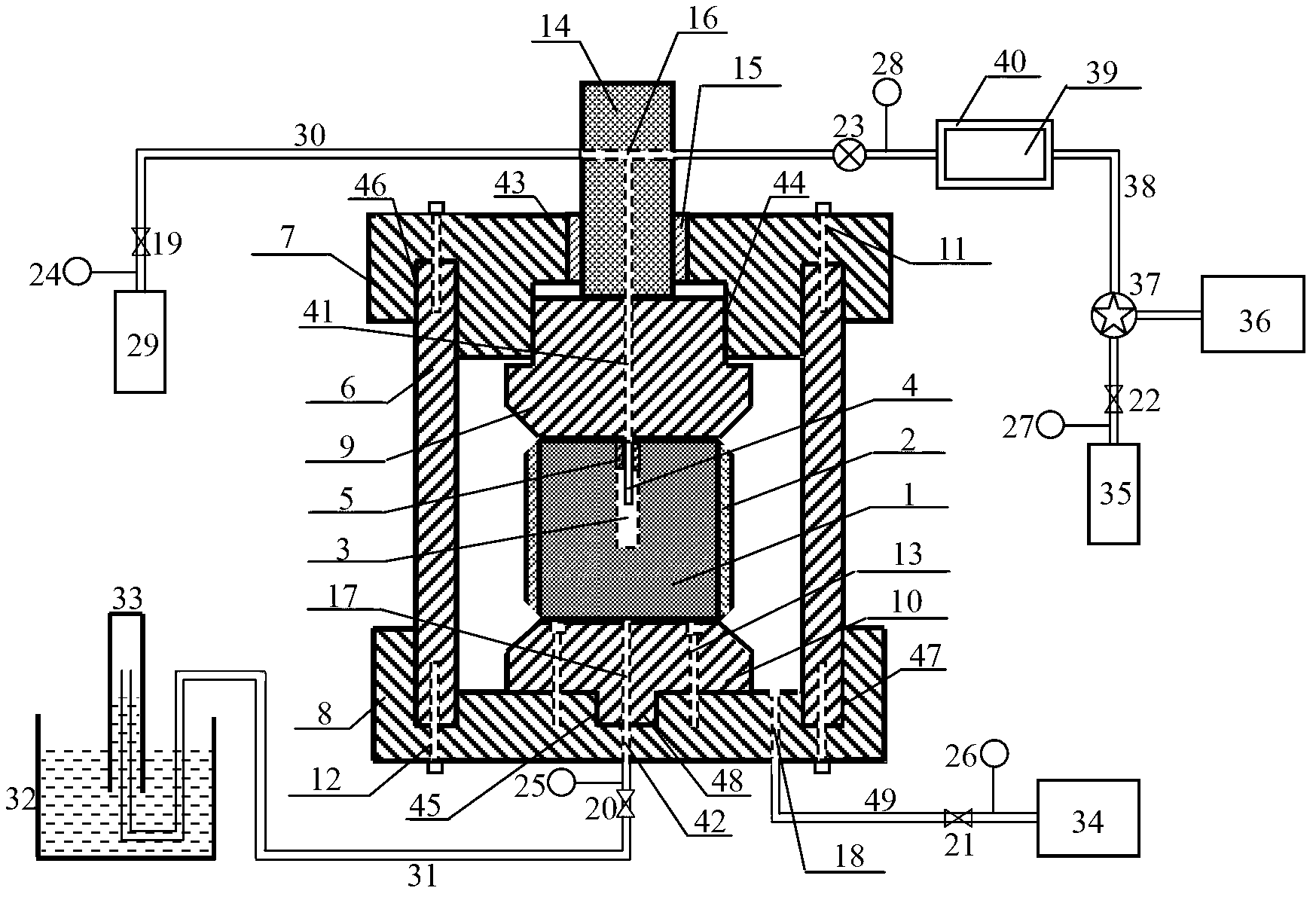

[0029] like figure 1 , figure 2 As shown, a low-permeability coal high-pressure gas circulation pulse fracturing anti-reflection experimental method, the experimental method uses a low-permeability coal high-pressure gas circulation pulse fracturing anti-permeability experimental device, specifically includes the following steps:

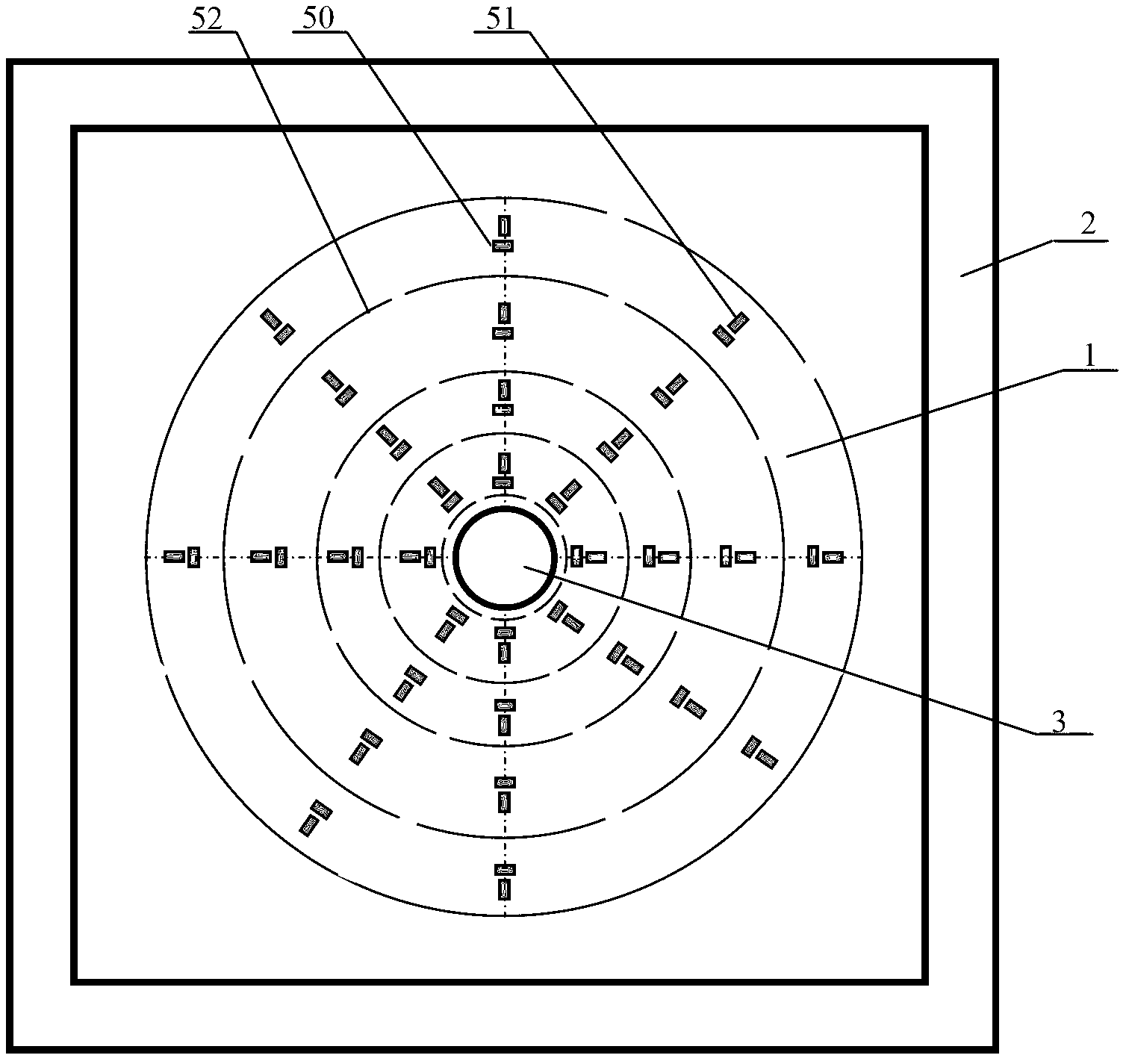

[0030] Step 1: Install the monitoring components

[0031]After the upper and lower end surfaces of the coal sample are polished smooth with sandpaper, a monitoring element is installed on the end surface, and the monitoring element is a circular segmented conductive coil 52 or a strain gauge; At the center of the circle, 5 groups of hoop segmented conductive coils 52 with different radii are pasted with high-strength resin glue. Each group of hoop segmented conductive coils 52 consists of 6 to 12 arc-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com