Ladder for mounting dynamic compactor arm frame

A technology for the installation of a dynamic tamping machine, which is applied to ladders, buildings, building structures, etc., and can solve problems such as increased safety hazards of booms, hidden dangers of ladders, and influence of booms by force, so as to eliminate potential safety hazards and be easy to use , Easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0028] For the convenience of description below, the "outside" referred to below refers to the direction toward the outside of the paper, and the "inner" refers to the direction toward the inside of the paper, which is consistent with the outer and inner directions of the drawings themselves.

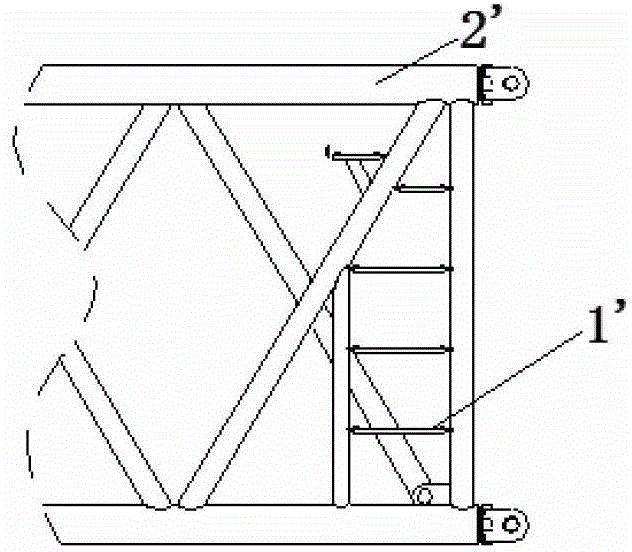

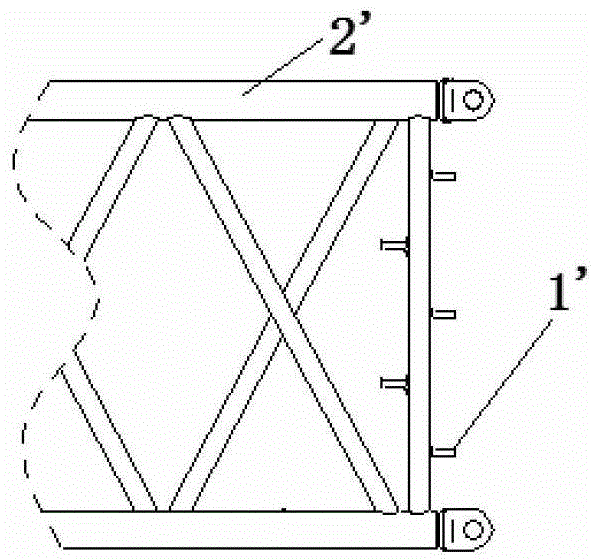

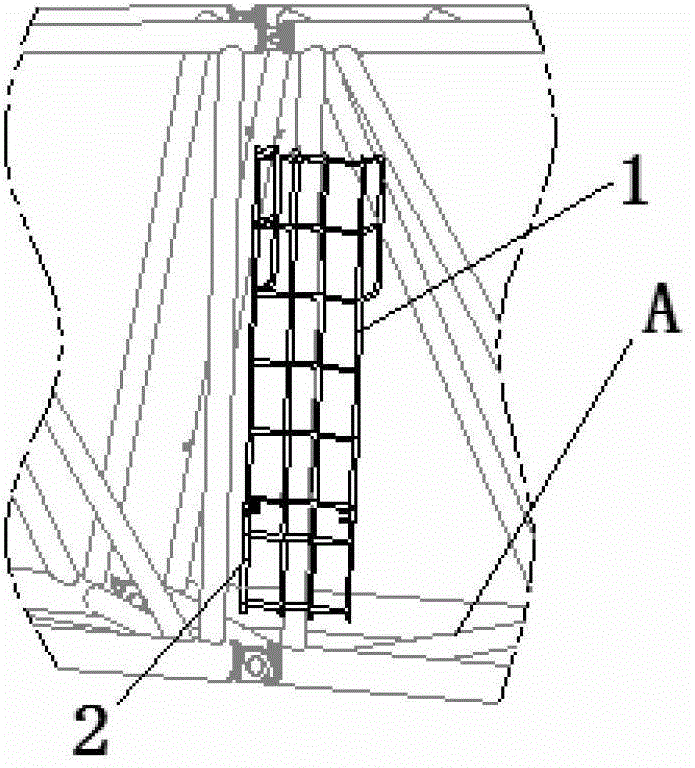

[0029] like Figure 3-Figure 5 As shown, the ladder provided by the present invention for installing the arm frame of the dynamic tamping machine includes a guardrail ladder 1, several first section ladders 2 and a first detachable connector 3, wherein: the guardrail ladder 1 and each first section ladder 2 A second detachable connecting piece 4 is provided respectively, through which the guardrail ladder 1 and each first step ladder 2 can be connected to the boom section A of the boom frame of the dynamic compaction machine. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com