Rear-arranged rear-drive type three connection rod rear suspension frame rear axle structure for motor

A three-link, rear suspension technology, applied in the direction of suspension, elastic suspension, cantilever mounted on the pivot, etc., can solve the problems of unsatisfactory rear axle structure, complex structure, etc., to meet the requirements of force transmission and Strength requirements, the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below with regard to specific accompanying drawings.

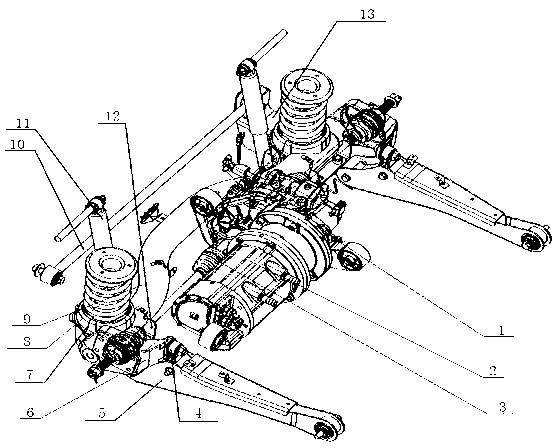

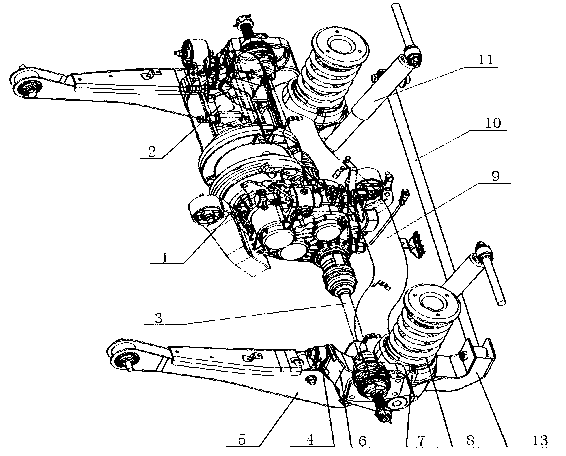

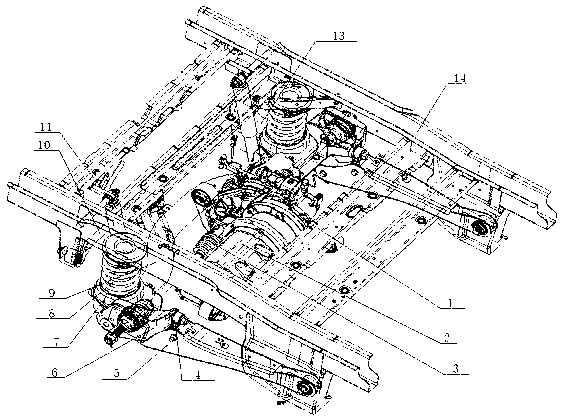

[0013] Such as figure 1 with figure 2 Shown is a motor rear drive type three-link rear suspension rear axle structure, including a shaft joint 6, a motor 2, a transmission 1, a drive shaft 3, a shock absorber 11, a pipe beam 9, a lower longitudinal arm 5 and a thrust Rod 10; the output shaft of the motor 2 is connected to the input end of the transmission 1, the output end of the transmission is connected to the drive shaft 3 arranged horizontally, and the two ends of the drive shaft are connected in series to the shaft joint 6 through gears, the shaft One side of the joint is fastened to the lower longitudinal arm 5 through the connecting bracket 4, and a hole is opened at the lower left corner of the other side of the shaft joint 6; The position protrudes backward, and the protruding part of the pipe beam can avoid the mutual interference between the pipe be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com