Handheld stirring rod and processing method thereof

A hand-held stirring and stirring rod technology, which is used in excitation or armature current control, home appliances, applications, etc., can solve problems such as damage to the motor and operation accidents of the cutter head, and achieve the effect of simple operation, safe and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

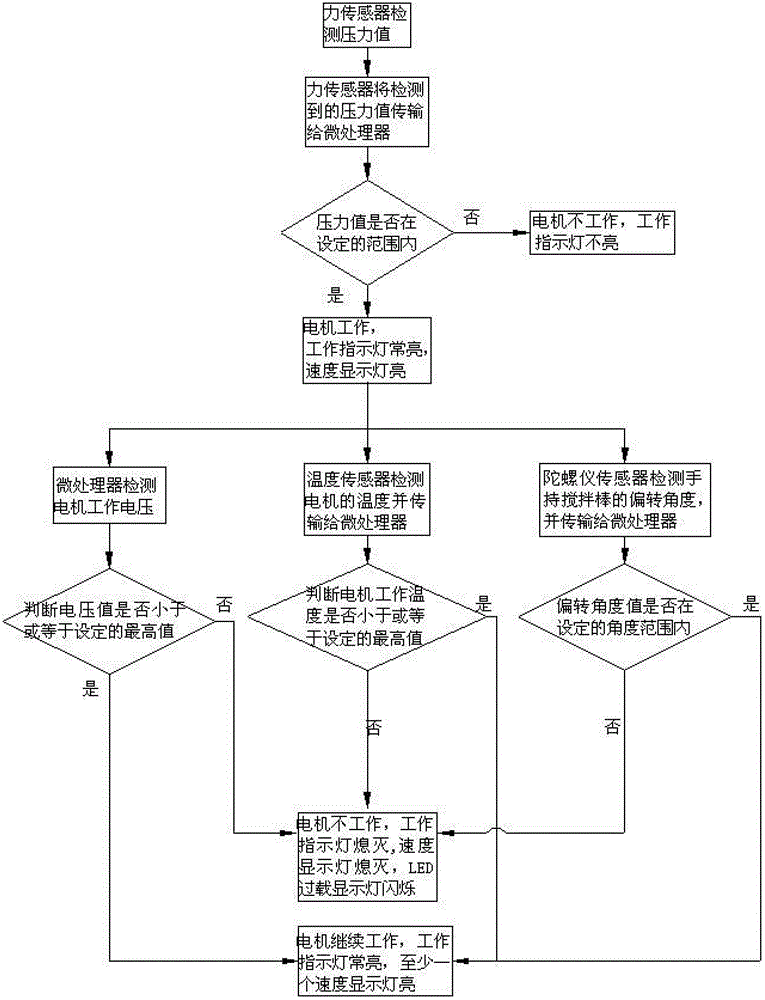

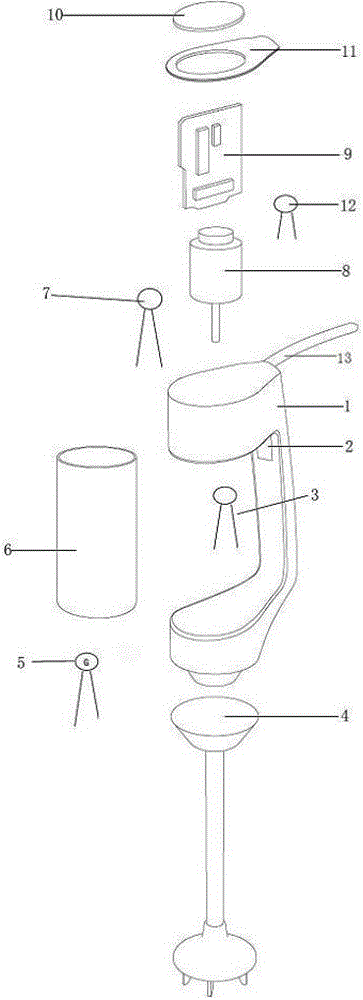

[0023] Design idea of the present invention is:

[0024] 1. A force sensor is used as an actuator of the hand-held stirring rod control system. A signal proportional to the applied force is generated by the force sensor, and the motor uses this signal to start the motor and adjust the speed. When a force of 100mN or more is applied to the force sensor, the motor will be activated, and when a force of 500mN is applied to the force sensor, the motor will reach the maximum speed. In this way, the user can obtain the desired speed continuously without presetting the speed.

[0025] 2. Adopt a motor with a speed sensor, and adjust the speed through the power of the motor. The rotational speed of the motor is directly proportional to the pressure applied by the user's finger on the switch.

[0026] 3. Use LED lights to display the power of the motor, and use flashing lights to show whether the motor is overloaded.

[0027] 4. A temperature sensor is used on the body of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com