Anti-poking angle spring lock

A marble lock and angle technology, applied in the field of locks, can solve problems such as inability to reset, and achieve the effect of improving the anti-dialing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

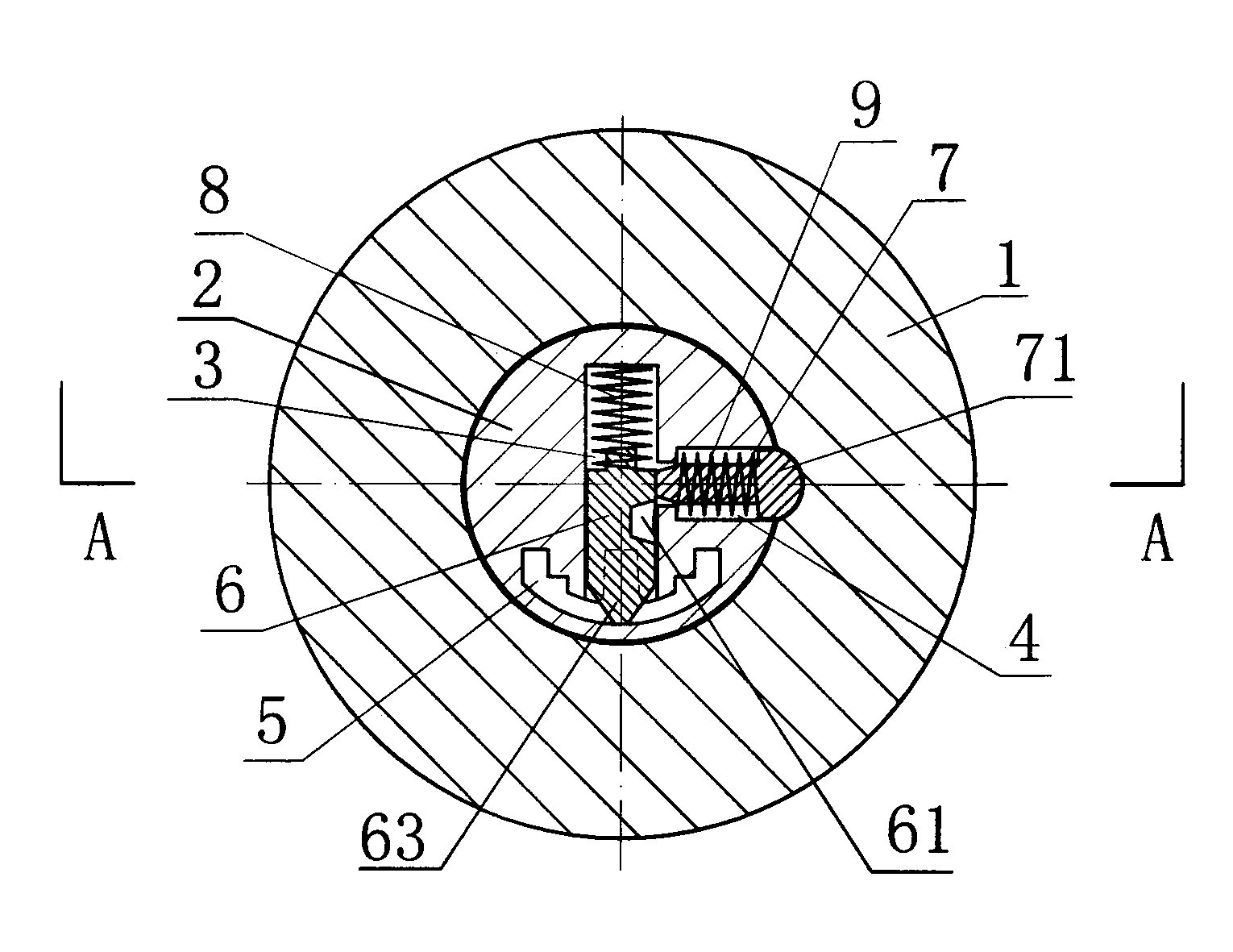

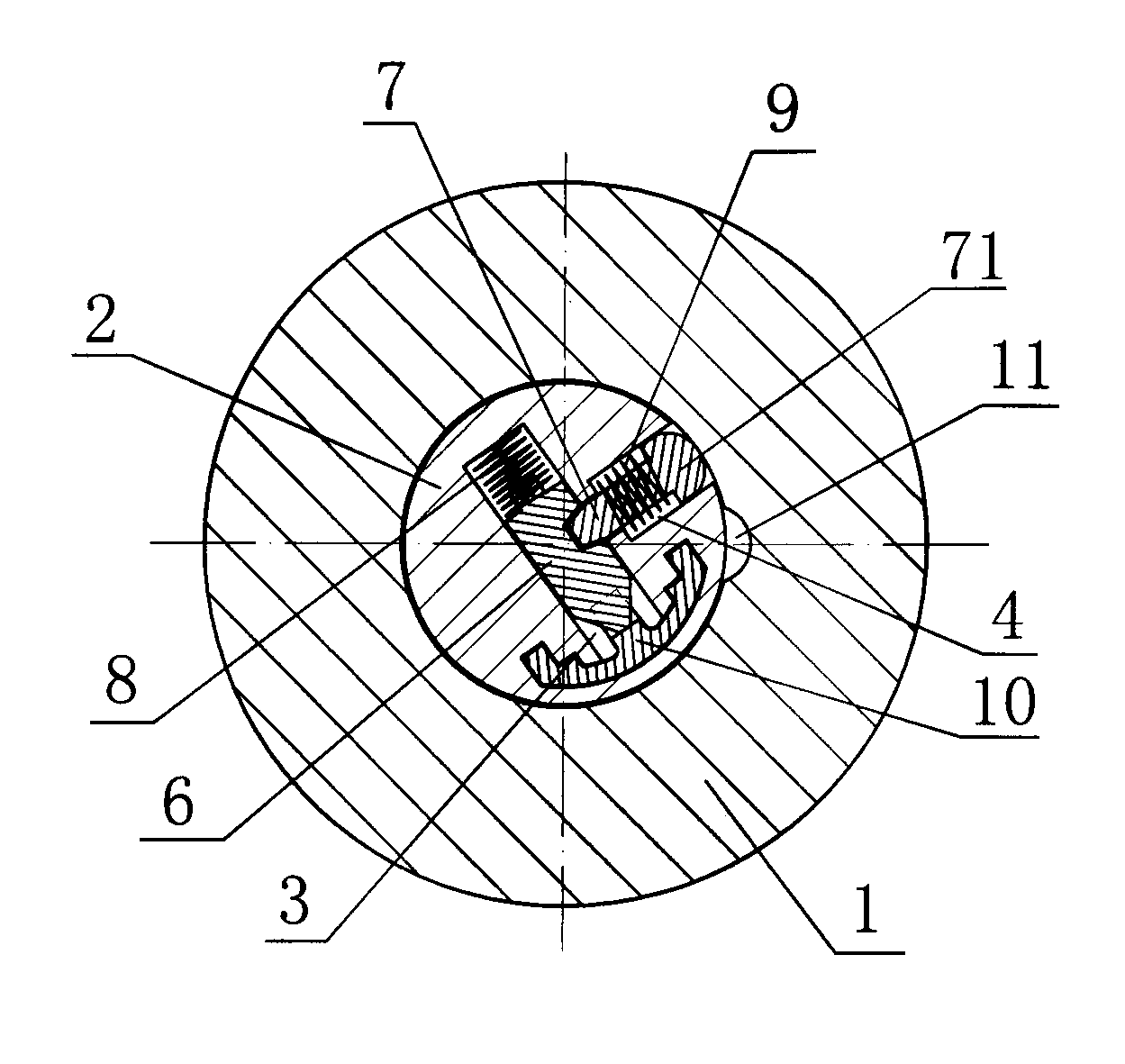

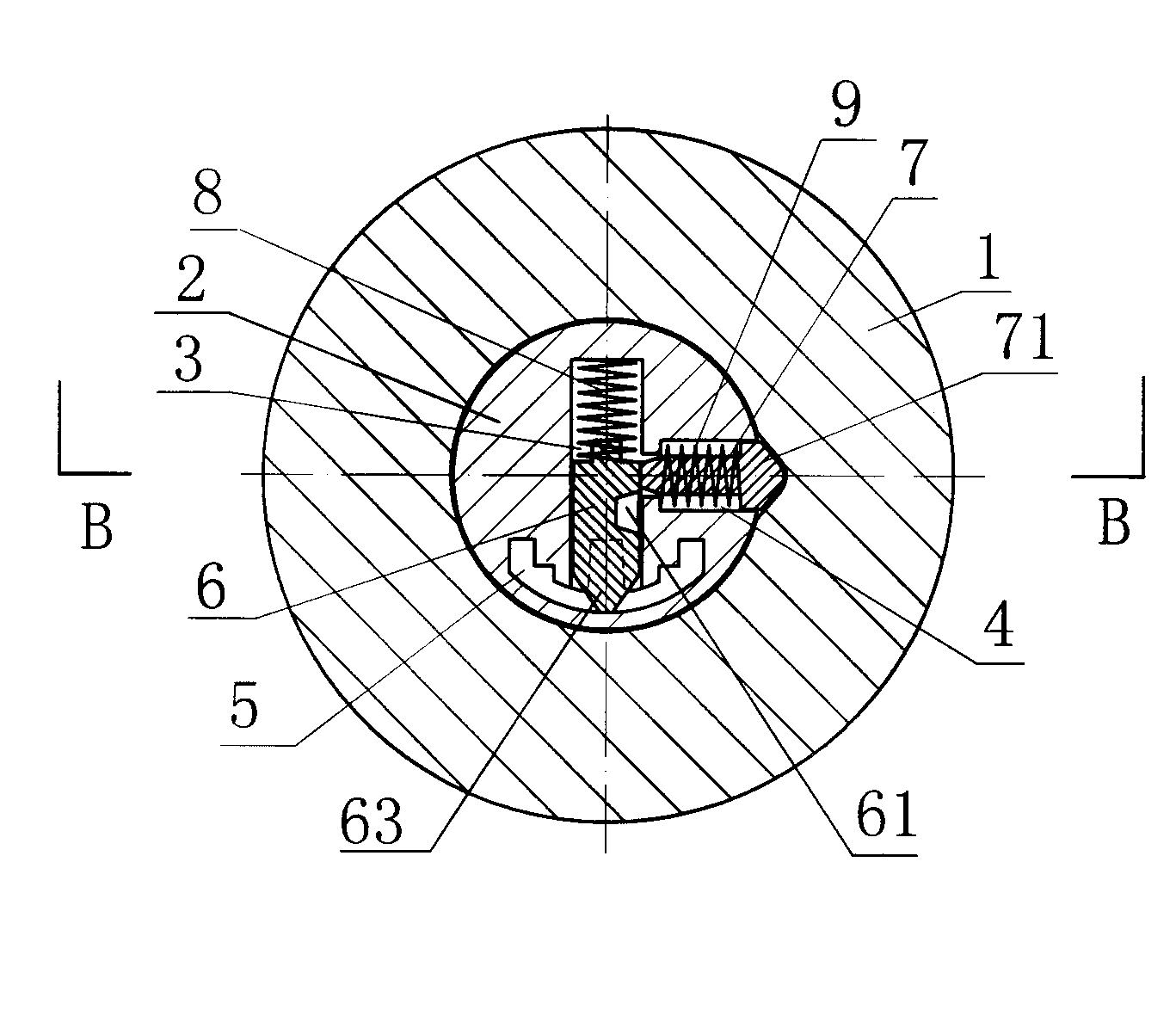

[0020] Referring to Figures 1 to 3, the anti-dialing angle tumbler lock of Embodiment 1 is composed of a lock body 1 and a lock cylinder 2 arranged in the lock body 1, wherein the lock cylinder 2 is provided with five groups along the axial direction of the lock cylinder 2. Arranged pinholes, each group of pinholes is composed of angle pinholes 3 and side sliding pinholes 4 arranged along the radial direction of the lock core 2 and the axes are perpendicular to each other, wherein the angle pinholes 3 are formed by the center of the lock core 2 The axis is formed by extending radially to both sides, one end of which communicates with the axial keyhole 5 located at the edge of the lock core 2, and the other end is a closed end; The radial extension of the lock core 2 is formed, one end of which communicates with the angle pin hole 3 , and the other end penetrates the outer wall of the lock core 2 .

[0021] Referring to Figures 1 to 5, the angle pinhole 3 is provided with an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com