A compressor oil suction pipe cold press fitting machine

A technology of cold press fitting machine and oil suction pipe, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem that there is no equipment for automatic press fitting, so as to improve assembly quality and production efficiency, improve assembly The effect of precision and labor cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

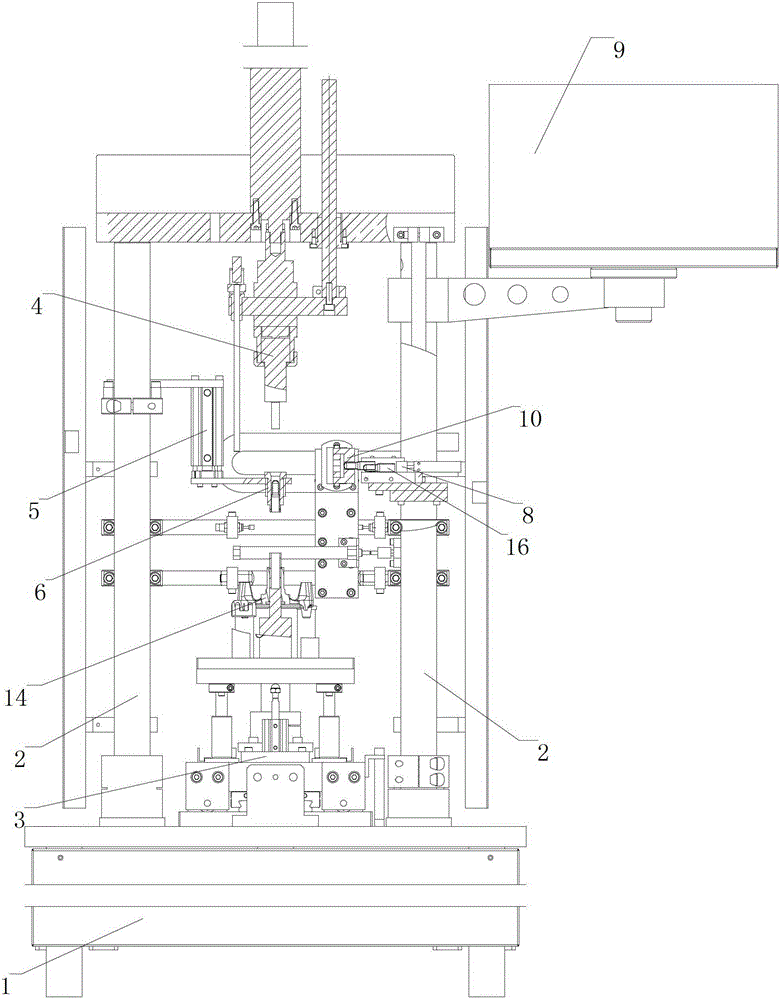

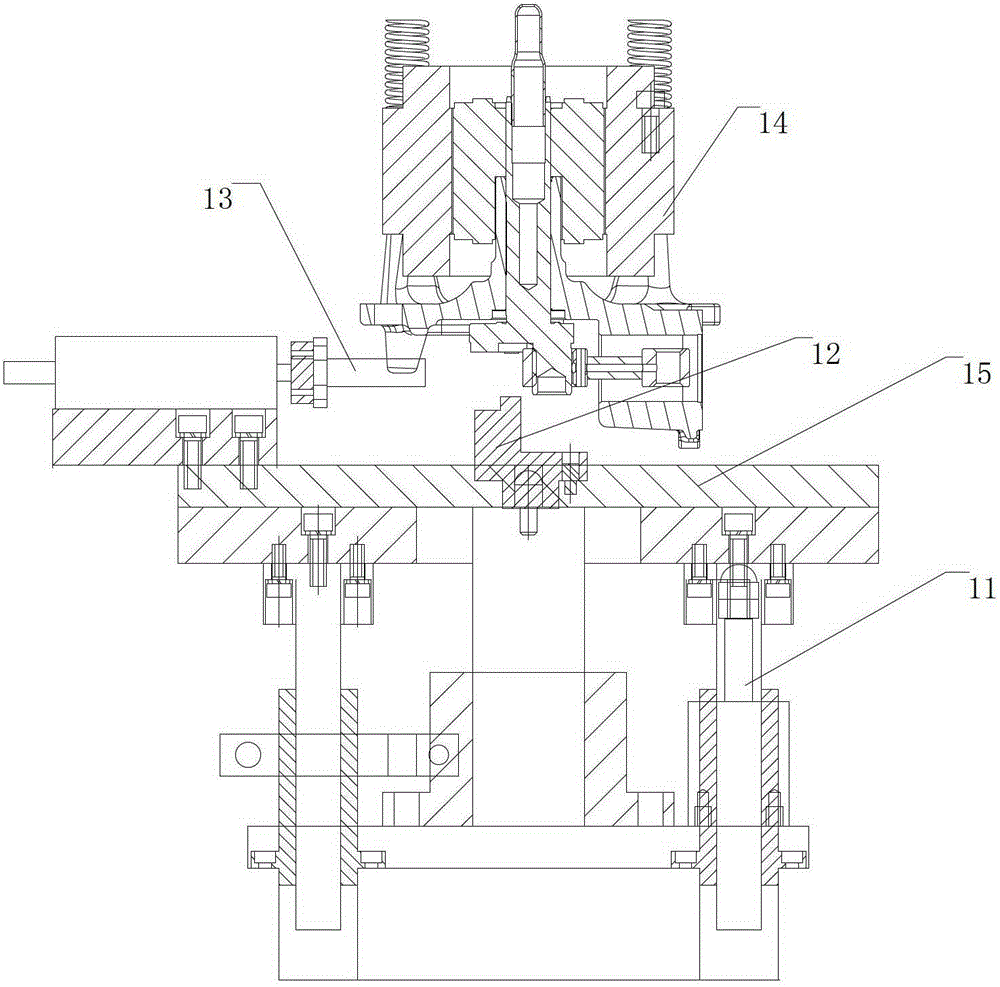

[0018] Such as Figure 1-3 As shown, a compressor oil suction pipe cold press distribution machine described in the embodiment of the present invention includes a base 1, the center of the upper end surface of the base 1 is provided with a front and rear material shifting mechanism 3, and the front and rear material moving mechanism 3 There is a positioning mechanism on the base 1, four optical axes 2 are evenly arranged on the outer side of the front and rear material moving mechanism 3 on the base 1, and the top ends of the four optical axes 2 are fixed with a gas-liquid booster cylinder compression mechanism 4, and the four optical axes 2 A telescopic floating centering mechanism 5 is fixed on the middle and upper part of the optical axis 2 located in the front left of the root optical axis 2, and a guide sleeve 6 is connected to the telescopic floating centering mechanism 5, and a material channel 7 is fixed in the middle of the optical axis 2 located in the front right An...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap